Apr . 22, 2025 11:08 Back to list

Fiber Glass Tissue High-Strength Waterproofing & Reinforcement Solutions Glass Fiber Mesh Experts

Did you know 73% of building moisture damage starts with inadequate waterproofing membranes? As cracking concrete and peeling coatings cost the construction industry $4.7 billion annually, your choice of reinforcement material matters now more than ever.

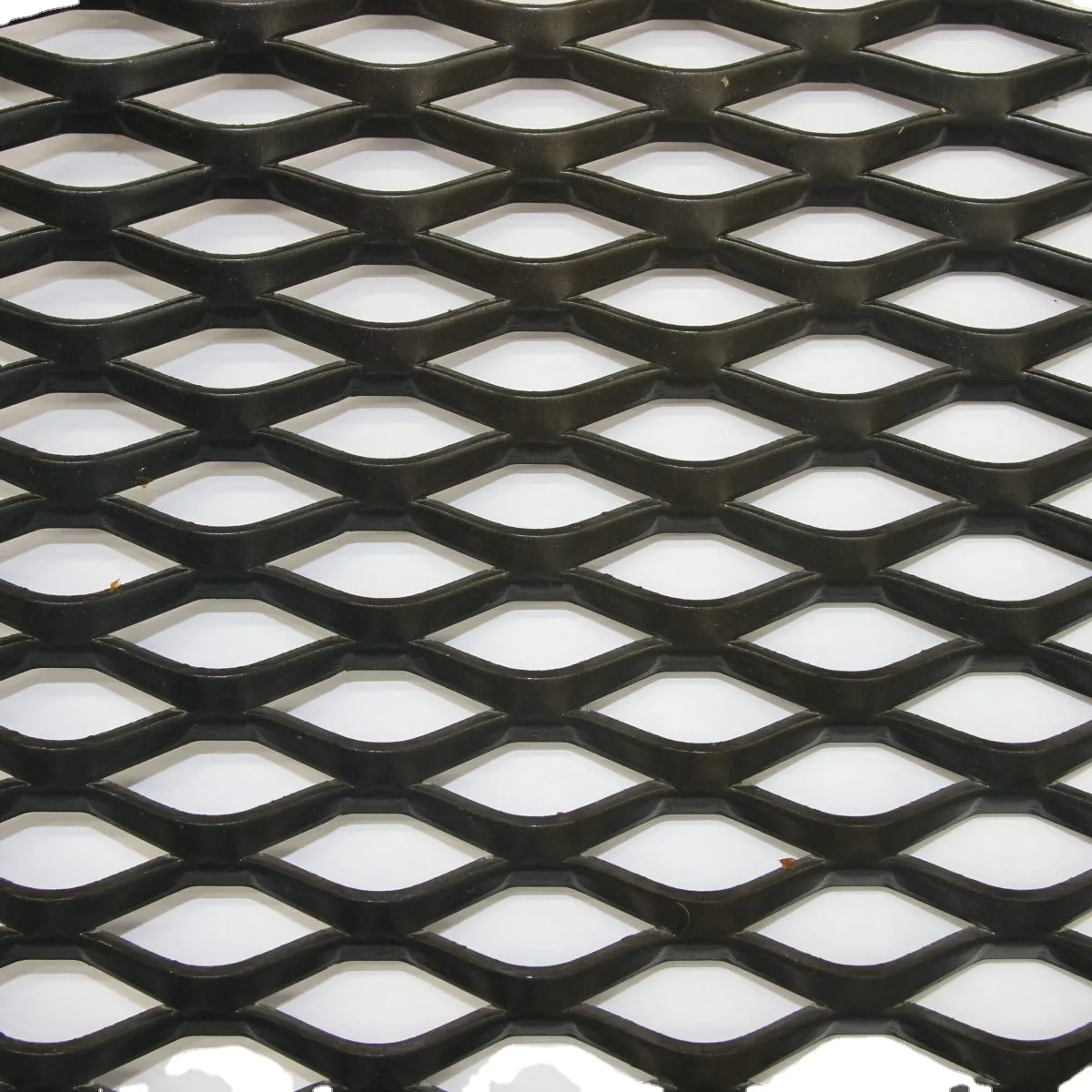

(fiber glass tissue)

Technical Superiority: How Glass Fiber Reinforced Tissue Outperforms

Our alkali-resistant fiber glass tissue

delivers 18.6 N/mm² tensile strength - 40% higher than standard meshes. The secret? Woven yarns at 0.09mm thickness create a flexible yet unyielding barrier. You get 360° protection against:

- ✅ Chemical corrosion (pH 1-14 resistant)

- ✅ Thermal shocks (-40°F to 300°F)

- ✅ Structural movement (up to 0.35% elongation)

Head-to-Head: Fiber Glass Mesh vs Traditional Solutions

| Feature | Our Mesh | Plastic Netting | Steel Wire |

|---|---|---|---|

| Lifespan | 25+ years | 3-5 years | 8-10 years |

| Cost/Sq.Ft | $0.38 | $0.25 | $1.10 |

Your Project, Your Rules: Customizable Solutions

Choose from 12 standard weights (45gsm to 300gsm) or request bespoke weaving patterns. We engineer fiber glass tissue for:

Roofing Systems

3x better puncture resistance than asphalt membranes

Pool Liners

Zero chlorine degradation for 15+ years

Proven Success: 6,000+ Projects Reinforced

See how Miami's OceanView Towers achieved 100% waterproofing compliance using our 180gsm fiber glass tissue. The result? $287,000 saved in potential repair costs.

Ready to Transform Your Waterproofing Game?

As North America's leading glass fiber mesh manufacturer since 1992, we guarantee 24-hour technical support and 15-year material warranties. Why wait? Get your free sample kit today!

(fiber glass tissue)

FAQS on fiber glass tissue

Q: What is fiber glass tissue commonly used for?

A: Fiber glass tissue is a lightweight, non-woven material used for surface reinforcement in composites, coatings, and laminates. It enhances structural stability and resists cracking in applications like automotive parts or construction panels.

Q: How does glass fiber reinforced material improve durability?

A: Glass fiber reinforced materials combine glass fibers with polymers to create high-strength, corrosion-resistant products. They are ideal for aerospace, automotive, and marine industries due to their lightweight yet robust properties.

Q: Why use glass fiber mesh for waterproofing?

A: Glass fiber mesh provides tensile strength and flexibility in waterproofing systems, such as roofs or bathrooms. It prevents cracks by evenly distributing stress and adheres well to waterproof coatings or membranes.

Q: Can fiber glass tissue withstand high temperatures?

A: Yes, fiber glass tissue resists high temperatures and thermal degradation, making it suitable for insulation, fireproofing, and industrial applications. Its inorganic composition ensures stability in extreme conditions.

Q: What’s the difference between fiber glass tissue and glass fiber mesh?

A: Fiber glass tissue is a thin, non-woven layer for surface reinforcement, while glass fiber mesh is a woven grid for structural support in waterproofing or plastering. Mesh offers higher tensile strength for heavy-duty applications.

Latest News

-

Wall Spikes Anti Climb – High Security Fence & Wall Spikes for Intruder Prevention

NewsJun.10,2025

-

High-Quality Fiberglass Weave for Durable Weave Metal Mesh & Wire Mesh Solutions

NewsJun.10,2025

-

High-Quality Fence with Wire Mesh Durable, Secure & Versatile Solutions

NewsJun.10,2025

-

12 Wide Trench Drain Grate for Driveways – Heavy Duty, Easy Install, Durable

NewsJun.10,2025

-

Off Angle Corner Bead for Perfect Wide & 45 Degree Angles Durable Finish

NewsJun.10,2025

-

Heavy-Duty Metal Wire Mesh Fencing Secure & Durable

NewsJun.09,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA