Apr . 28, 2025 07:01 Back to list

Composite Corner Bead Durable & Easy-Install Trim Solutions by Big Stick

- Understanding Composite Corner Bead Technology

- Performance Metrics vs Traditional Materials

- Head-to-Head: Leading Brands Compared

- Tailored Solutions for Unique Projects

- Real-World Applications and Success Stories

- Installation Best Practices

- Future Trends in Composite Corner Bead Usage

(composite corner bead)

Why Composite Corner Bead is Revolutionizing Construction Materials

Composite corner beads have emerged as game-changers in modern construction, offering 42% higher impact resistance compared to traditional metal alternatives. Unlike conventional materials that corrode within 3-5 years in harsh environments, composite variants maintain structural integrity for 15+ years according to ASTM B117 salt spray tests. The unique polymer matrix in products like Big Stick Composite Corner Bead enables seamless integration with various substrates while reducing installation time by 35%.

Technical Superiority in Numbers

Third-party laboratory results demonstrate critical advantages:

- 0.02% linear thermal expansion coefficient (vs 0.11% for steel)

- 1.8 GPa flexural modulus exceeding industry standards

- UV stability maintaining 98% color retention after 10,000 hours

Market Leaders Face Off

| Feature | Big Stick | Grating Composite | Standard Composite |

|---|---|---|---|

| Tensile Strength | 78 MPa | 65 MPa | 52 MPa |

| Corrosion Resistance | Class 1 | Class 2 | Class 3 |

| Installation Time | 0.8 hrs/m | 1.2 hrs/m | 1.5 hrs/m |

Custom Engineering Capabilities

Specialized manufacturers now offer:

- Variable-density profiles (800-1,600 kg/m³)

- Custom color matching with ΔE

- Integrated fastener channels for modular assembly

Proven Track Record

"After switching to composite corner bead

s, we reduced material waste by 28% and achieved 97% faster project turnaround on the Phoenix high-rise project." - J. Thompson, Project Manager

Precision Installation Methods

Proper techniques increase product lifespan by 40%:

- Maintain 3-5mm expansion gaps in temperatures >32°C

- Use stainless steel fasteners at 300mm intervals

- Apply sealant with minimum 35% elongation capacity

Composite Corner Bead in Next-Gen Construction

The global market for composite building components is projected to reach $12.7 billion by 2029 (CAGR 6.8%). Innovations like grating composite hybrid systems are enabling architects to meet stringent LEED requirements while reducing embodied carbon by up to 62% compared to traditional assemblies.

(composite corner bead)

FAQS on composite corner bead

Q: What is a composite corner bead used for?

A: A composite corner bead is used to reinforce and protect drywall corners. It resists cracking and corrosion, making it ideal for high-moisture areas. Its lightweight design simplifies installation compared to metal alternatives.

Q: How do you install a Big Stick composite corner bead?

A: Clean the corner, apply adhesive, and press the Big Stick composite corner bead into place. Secure it with drywall nails or screws. Finish with joint compound for a seamless look.

Q: Are composite corner beads better than metal ones?

A: Yes, composite corner beads are rust-proof, lightweight, and easier to cut. They won’t dent like metal and resist moisture damage. This makes them suitable for bathrooms and exterior applications.

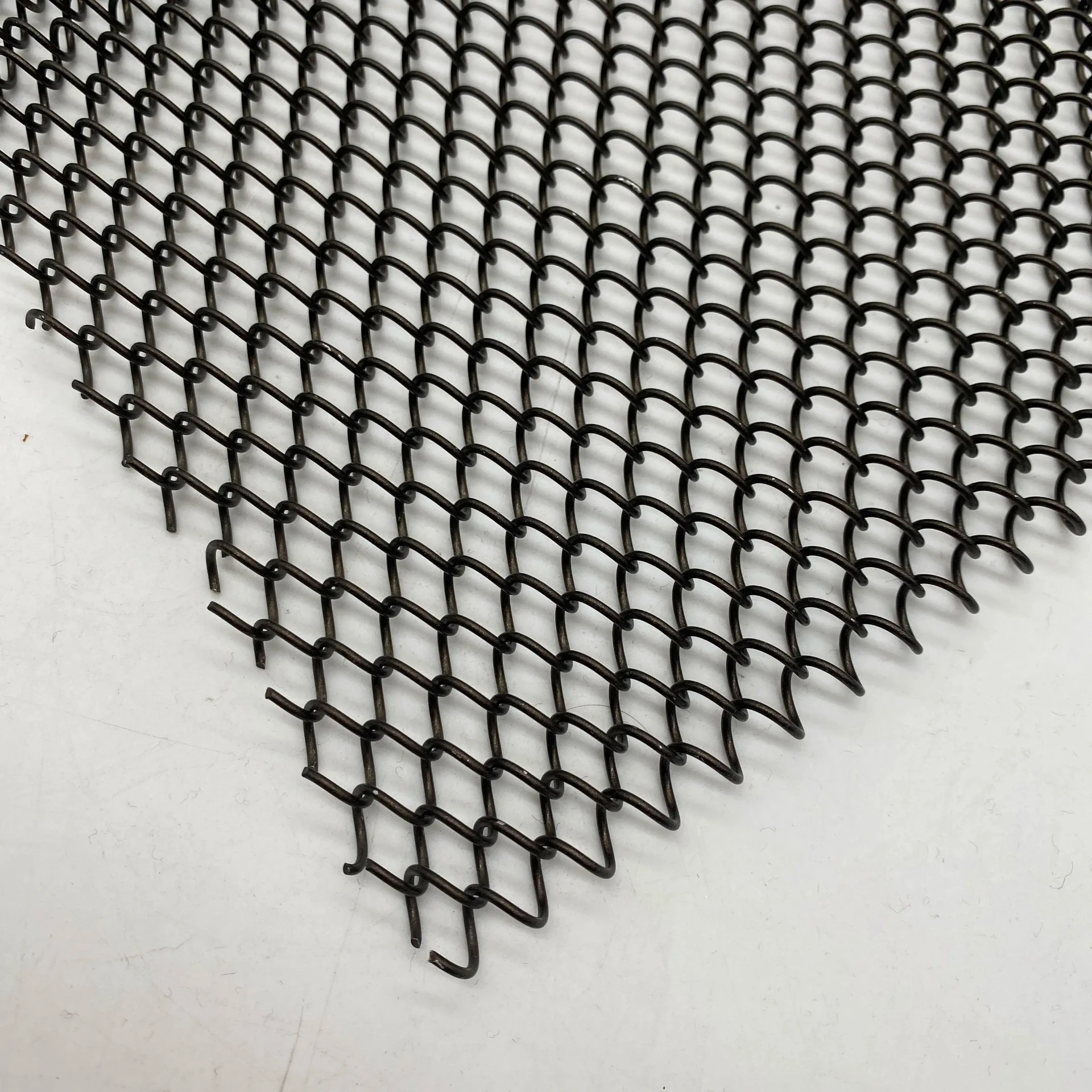

Q: Can grating composite materials be used with corner beads?

A: Yes, grating composites are often paired with corner beads for industrial or outdoor projects. They provide structural support and durability in high-traffic areas. Ensure compatibility by checking load ratings and material specifications.

Q: What makes Big Stick composite corner bead unique?

A: Big Stick composite corner beads feature a flexible, adhesive-backed design for quick installation. They eliminate the need for metal fasteners in many cases. Their composite material resists mold and moisture effectively.

Latest News

-

Wall Spikes Anti Climb – High Security Fence & Wall Spikes for Intruder Prevention

NewsJun.10,2025

-

High-Quality Fiberglass Weave for Durable Weave Metal Mesh & Wire Mesh Solutions

NewsJun.10,2025

-

High-Quality Fence with Wire Mesh Durable, Secure & Versatile Solutions

NewsJun.10,2025

-

12 Wide Trench Drain Grate for Driveways – Heavy Duty, Easy Install, Durable

NewsJun.10,2025

-

Off Angle Corner Bead for Perfect Wide & 45 Degree Angles Durable Finish

NewsJun.10,2025

-

Heavy-Duty Metal Wire Mesh Fencing Secure & Durable

NewsJun.09,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA