Ago . 28, 2025 16:40 Voltar para a lista

Extending Lifespan of Heavy-Duty Channel Drain Covers

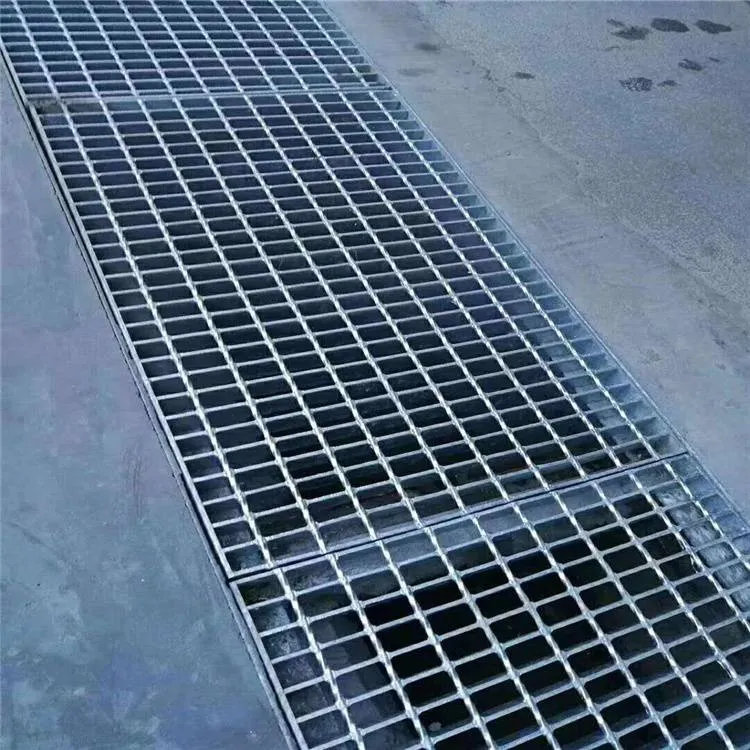

Robust drainage systems are fundamental infrastructure, silently managing water flow in demanding environments like industrial facilities, busy roadways, ports, and commercial driveways. Central to these systems are the visible and load-bearing components: the covers. Channel drain covers, including variants like trench grate covers e driveway drain grates, endure immense pressure, constant traffic, and harsh environmental conditions. Ensuring these critical components achieve their maximum operational lifespan is not just a matter of cost savings; it's essential for safety, functionality, and minimizing operational disruptions. For manufacturers supplying large quantities of these heavy-duty solutions, understanding and communicating longevity factors is paramount. This article details key strategies for maximizing the service life of channel drain grates and related covers.

Material Mastery for Channel Drain Grates

The foundation of longevity lies in the inherent properties of the material used. For channel drain grates destined for heavy-duty applications, material selection is non-negotiable. High-grade cast iron, particularly ductile iron, remains a premier choice due to its exceptional strength-to-weight ratio, impressive impact resistance, and inherent durability under repetitive loading. Ductile iron's ability to flex slightly under stress without fracturing makes it ideal for dynamic loads encountered on roads and industrial sites.

Precision casting techniques are crucial. Consistent wall thickness, freedom from casting defects like porosity or inclusions, and accurate dimensional tolerances ensure the channel drain grate can distribute loads effectively and fit perfectly within the channel frame. Surface treatment is the final defense. High-quality coatings, such as specialized epoxy paints or hot-dip galvanizing, provide a robust barrier against corrosion caused by water, de-icing salts, chemicals, and atmospheric pollutants. The integrity of this coating directly impacts the underlying metal's lifespan. Manufacturers committed to longevity invest heavily in controlled casting processes and rigorous coating specifications tailored to the expected environmental challenges.

Precision Installation of Trench Grate Covers

Even the most robust trench grate cover can fail prematurely if installation is subpar. Correct installation begins with meticulous preparation of the channel or trench itself. The supporting structure, typically concrete, must be level, stable, and capable of bearing the anticipated loads without settling or cracking. Settling beneath the frame is a primary cause of cover misalignment and failure.

O trench grate cover frame must be set accurately within this prepared structure. It needs to be level, securely embedded, and properly supported along its entire length. Any voids or uneven support create stress points where the trench grate cover can bend or crack under load. The gap between the frame and the surrounding paving must be correctly filled with appropriate flexible sealants to prevent movement and ingress of debris and water, which can undermine the foundation. Crucially, the trench grate cover itself must sit perfectly flush and level within its frame, with no rocking or protrusion. This ensures loads are transferred evenly across the frame and cover, preventing point loading and premature fatigue. Installation manuals provided by the manufacturer must be followed meticulously for optimal performance.

Proactive Maintenance for Channel Drain Cover Integrity

Longevity isn't solely about initial quality and installation; ongoing maintenance is vital. Regular inspection and cleaning form the core of preserving channel drain cover integrity. Debris accumulation – leaves, sediment, gravel, litter – is the primary enemy. It obstructs water flow, leading to pooling and potential overflow. More critically, trapped debris accelerates corrosion by holding moisture and corrosive agents against the metal. It can also physically jam the channel drain cover, preventing proper seating or making removal difficult, potentially damaging the frame or the cover itself during cleaning.

Scheduled cleaning routines, using appropriate tools, are essential. Inspections should look for signs of wear: coating damage, deformation or bending of the grate bars, cracks, and any loosening of the cover within the frame. Addressing minor issues like localized coating damage promptly with touch-up paint specified by the manufacturer can prevent accelerated corrosion. Ensuring that fixing mechanisms, remain secure and functional is also crucial for safety and preventing cover movement.

Optimizing Driveway Drain Grates for Traffic Loads

Driveway drain grates face unique challenges. They must handle not just static vehicle weights but dynamic loads, impact forces (like sudden braking or turning), and potentially high-frequency traffic cycles. Selecting the correct load class based on the specific driveway application is the first critical step. Under-specifying the driveway drain grate guarantees premature failure.

Design features also play a significant role. The pattern of the grate bars influences both strength and debris handling. Patterns offering larger open areas improve flow but require careful engineering to maintain load-bearing capacity. Bar thickness and depth are critical factors in stiffness and resistance to bending. The bearing surface area where the driveway drain grate rests on the frame should be sufficient to distribute the load effectively without excessive point pressure. For areas expecting very heavy or frequent traffic, reinforced designs, potentially with additional cross-bracing or thicker sections, may be necessary. Ensuring the frame design complements the grate, providing ample support, is equally important for the overall system's longevity under driveway conditions.

FAQs about Channel Drain Covers

What is the primary cause of premature failure in channel drain grates?

The most common causes are corrosion due to inadequate material quality or coating failure, physical damage from impact or overload, and improper installation leading to misalignment, rocking, or uneven load distribution. Regular inspection helps identify these issues early.

How often should trench grate covers be inspected and cleaned?

The frequency depends on the environment. High-traffic areas or locations prone to debris (like near trees) may require inspection and cleaning quarterly or even monthly. Less demanding sites might suffice with biannual checks. Always inspect after major storms or known impact events.

Can a damaged channel drain cover coating be repaired?

Yes, localized damage to the coating on a channel drain cover can often be effectively repaired. It's crucial to clean the damaged area thoroughly (remove rust), apply a suitable primer specified by the manufacturer, and then use the correct touch-up paint. This prevents corrosion from spreading under the coating.

What load rating is typically required for driveway drain grates?

The required load class for driveway drain grates depends on the vehicle types using the driveway. Residential driveways typically require Class C250 or D400 (EN 124). Driveways expecting delivery trucks or garbage trucks usually need Class E600 or F900. Always consult local regulations and a structural engineer for specific requirements.

Why is frame support critical for trench grate covers?

The frame provides the essential foundation for the trench grate cover. If the frame is inadequately supported, settles unevenly, or is installed incorrectly, the trench grate cover will not sit level. This leads to rocking, point loading, and ultimately bending, cracking, or failure of the cover under load, drastically reducing its lifespan. Proper frame bedding and support are non-negotiable.

Maximizing the lifespan of heavy-duty channel drain covers, trench grate covers, e driveway drain grates is a multi-faceted endeavor requiring attention from design through installation and ongoing care. It starts with selecting high-quality materials, like ductile iron, manufactured to precise standards with durable corrosion protection. Precision installation, ensuring a level, stable, and fully supported frame with the cover sitting perfectly flush, is critical to prevent stress points and premature failure. Implementing a proactive maintenance regime of regular inspection and thorough cleaning prevents debris buildup and allows for early detection and repair of minor issues like coating damage. Finally, selecting the correct load class and design, especially for high-traffic driveway drain grates, ensures the product is engineered to withstand the specific demands of its environment. By adhering to these principles, manufacturers and end-users alike can ensure these vital drainage components deliver decades of reliable, safe, and efficient service.

Últimas notícias

-

Proper Installation Methods for Aluminum Floor Grating

NotíciasAug.28,2025

-

Metal Mesh Corner Bead Impact Protection Benefits

NotíciasAug.28,2025

-

Installing Drywall Corner Molding Step-by-Step Guide

NotíciasAug.28,2025

-

Custom Shapes for Specialized Aluminium Plaster Beads

NotíciasAug.28,2025

-

Aluminium Walkway Mesh Providing Slip-Resistant Ventilation

NotíciasAug.28,2025

Nossa empresa possui excelentes designers de desenho de grades de aço CAD, que podem fornecer aos clientes um design de layout de grades de aço perfeito e atender melhor aos requisitos especiais dos clientes para produtos. Temos aderido ao princípio empresarial de "qualidade em primeiro lugar, cliente em primeiro lugar", com produtos de alta qualidade, preços razoáveis e o tempo de entrega mais rápido, oferecemos de todo o coração aos clientes uma gama completa de serviços! Bem-vindos, novos e antigos clientes para cooperar sinceramente e criar brilho juntos!

Contate-nos

BEM-VINDO À NOSSA EMPRESA!

Obrigado pelo seu interesse em nossos serviços! Se você tiver alguma dúvida ou quiser reservar um serviço, não hesite em nos contatar. Nossa equipe é dedicada a fornecer a você o mais alto nível de serviço e suporte, e estamos comprometidos em trabalhar com você para fazer do seu evento um sucesso.

E-mail de serviço

Telefone de serviço

Contate-nos

- Telefone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Endereço: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA