Sep . 19, 2025 10:45 Back to list

Wire Mesh Conveyor Belts: High Performance & Durability

Introduction to High-Performance Wire Mesh Conveyor Belts

In industrial automation, the efficiency and reliability of material handling systems are paramount. Wire mesh conveyor belts represent a critical component in numerous demanding applications, facilitating continuous product movement through various processing stages. Engineered for durability and versatility, these belts are indispensable in environments requiring high temperatures, corrosive conditions, precise product support, or efficient drainage and airflow. This comprehensive guide delves into the technical aspects, applications, and strategic considerations for deploying these essential industrial assets.

Our focus extends to advanced stainless steel variants, including 201, 304, 316L, and 310S, each selected for specific performance characteristics under extreme operational stresses. These materials ensure optimal performance across a spectrum of industrial sectors, from petrochemical and metallurgy to food processing and heat treatment. Understanding the intricate design, manufacturing precision, and tailored solutions available is key to optimizing operational efficiency and achieving long-term reliability in your industrial processes.

Current Industry Trends in Wire Mesh Belt Technology

The industrial landscape for wire mesh conveyor belts is continuously evolving, driven by demands for increased efficiency, sustainability, and adaptability. Key trends shaping this sector include:

- Emphasis on Advanced Materials: Beyond standard stainless steels, there's growing interest in specialized alloys and composite materials that offer superior performance in ultra-high temperatures, aggressive chemical environments, or specific wear resistance needs. The demand for 316L for enhanced corrosion resistance and 310S for extreme thermal stability continues to rise.

- Integration with Smart Manufacturing (Industry 4.0): Future mesh conveyor belt systems are being designed with compatibility for sensors and IoT devices. This enables real-time monitoring of belt tension, temperature, wear, and throughput, allowing for predictive maintenance and optimized operational parameters.

- Energy Efficiency: Manufacturers are developing lighter-weight designs and innovative weave patterns that reduce friction and power consumption without compromising strength. This focus on energy optimization contributes to lower operational costs and reduced environmental impact.

- Customization and Modularity: The trend towards highly specific processing requirements means a greater need for customized belt designs. Modular components and flexible manufacturing processes allow for quicker adaptation to unique application demands, including varying widths, pitches, and edge configurations.

- Enhanced Hygiene Standards: Particularly in food and pharmaceutical industries, there's a constant push for easily cleanable, sanitary wire conveyor belt designs that minimize bacterial harborage and comply with increasingly stringent regulatory standards such as FDA and USDA guidelines.

Manufacturing Process Flow of Wire Mesh Conveyor Belts

The production of high-quality stainless steel wire mesh conveyor belt involves a precise series of steps, ensuring structural integrity and optimal performance. Our manufacturing process emphasizes meticulous control from raw material selection to final quality assurance.

Process Steps:

-

Material Selection and Preparation: We utilize premium grades of stainless steel wire, including 201, 304, 316L, and 310S, sourced from certified mills. Each material offers distinct advantages:

- 201 Stainless Steel: Cost-effective, good strength, suitable for less corrosive environments.

- 304 Stainless Steel: Excellent general-purpose corrosion resistance, suitable for food processing and moderately high temperatures.

- 316L Stainless Steel: Superior corrosion resistance, especially against chlorides, ideal for marine, chemical, and pharmaceutical applications.

- 310S Stainless Steel: Exceptional high-temperature resistance (up to 1150°C), perfect for furnaces, heat treatment, and annealing processes.

-

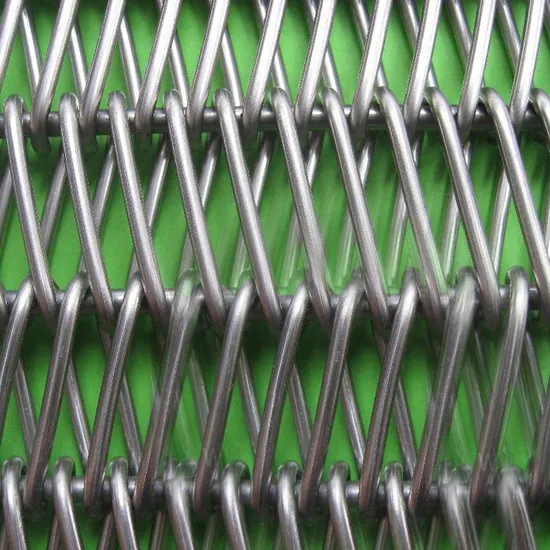

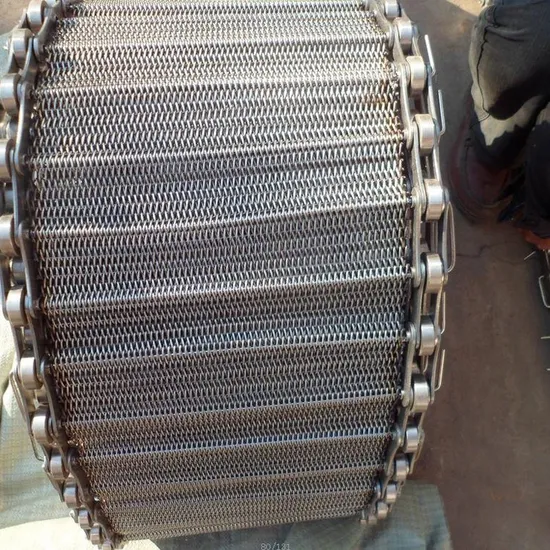

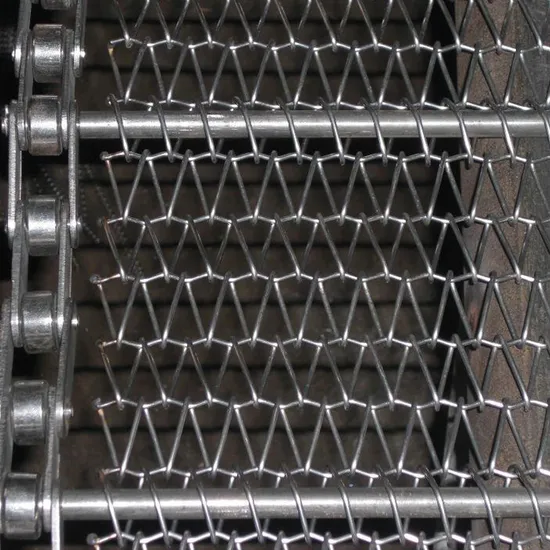

Weaving/Spiral Formation: For balanced weave or compound weave belts, precision machinery forms individual spirals. These spirals are then interlocked with connecting rods. For chain-driven belts, side chains are integrated during this stage.

Step 1: Wire Drawing & Annealing (to desired diameter) Step 2: Spiral Winding (forming individual coils) Step 3: Rod Insertion (interconnecting spirals) Step 4: Edge Finishing (welding, clinching, or self-edging) - Rod Insertion & Edge Finishing: Cross rods are inserted through the interlocked spirals, followed by precise welding or clinching of the rod ends to secure the belt structure and prevent unraveling. Various edge treatments are available, including welded, knuckled, or plate edges, depending on the application's specific requirements for strength and product retention.

- Welding & Assembly (for specific belt types): For some complex or heavier-duty wire mesh belts, additional welding processes, such as TIG or resistance welding, are employed to reinforce structural points or attach specific components like flights or side guards.

- Heat Treatment (Post-Fabrication): For belts operating under extreme thermal cycling or requiring enhanced metallurgical properties, a post-fabrication heat treatment (e.g., annealing or stress relieving) may be performed to improve ductility, reduce residual stresses, and optimize material grain structure.

- Surface Treatment & Cleaning: Belts may undergo passivation to enhance corrosion resistance by forming a protective oxide layer. Thorough cleaning removes any manufacturing residues, particularly crucial for food-grade applications.

- Quality Control & Testing: Each wire mesh conveyor belts undergoes rigorous inspection to meet international testing standards such as ISO 9001 for quality management and ASTM standards for material composition and mechanical properties. This includes visual inspection for defects, dimensional checks (width, length, pitch uniformity), tensile strength tests, and sometimes metallurgical analysis. Our belts are engineered for a typical service life exceeding 5 years under optimal conditions, often reaching 10-15 years with proper maintenance.

In typical application scenarios within the petrochemical and metallurgy industries, the precise control over material composition and fabrication ensures significant advantages such as energy saving through optimized belt weight-to-strength ratios, and unparalleled corrosion resistance, particularly with 316L and 310S variants, minimizing downtime and extending operational life.

Technical Specifications and Material Characteristics

Understanding the detailed technical specifications and material properties is crucial for selecting the optimal wire mesh conveyor belts for a given application. The following table outlines key parameters and material characteristics:

Typical Wire Mesh Conveyor Belt Specifications

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Material Grades | Stainless Steel (201, 304, 316L, 310S), High-Nickel Alloys | Specific to application |

| Wire Diameter | Diameter of the individual wires forming the mesh | 0.9 mm to 3.5 mm (0.035" to 0.138") |

| Spiral Pitch | Distance between centers of adjacent spirals | 5 mm to 30 mm (0.2" to 1.2") |

| Rod Pitch | Distance between centers of adjacent cross rods | 8 mm to 60 mm (0.3" to 2.4") |

| Belt Width | Overall width of the conveyor belt | 150 mm to 4000 mm (6" to 157") |

| Operating Temperature | Maximum continuous operating temperature | Up to 1150°C (2100°F) for 310S |

| Open Area Percentage | Ratio of open space to total surface area | 20% to 80% (variable by weave type) |

| Tensile Strength | Maximum stress the belt can withstand before breaking | Specific to material grade and weave pattern |

Comparative Material Properties for Wire Mesh Belts

| Stainless Steel Grade | Primary Advantage | Max Temp (Continuous) | Corrosion Resistance | Applications |

|---|---|---|---|---|

| 201 | Cost-effectiveness, good strength | ~700°C (1292°F) | Moderate | General conveying, low-corrosion environments |

| 304 | General-purpose, excellent strength | ~870°C (1600°F) | Good | Food processing, general heat treatment |

| 316L | Superior corrosion (especially chlorides) | ~925°C (1700°F) | Excellent | Chemicals, marine, pharmaceutical, demanding wash-down |

| 310S | Exceptional high-temperature resistance | ~1150°C (2100°F) | Good (oxidizing environments) | Furnace applications, brazing, sintering, glass annealing |

These specifications highlight the precise engineering involved in matching the right wire mesh belt to the operational demands. Custom configurations are routinely developed to meet unique client requirements, ensuring optimal fit and performance for specific applications like petrochemical reactors or metallurgy heat treatment furnaces.

Diverse Application Scenarios

The adaptability of wire mesh belts makes them indispensable across a wide array of industries. Their open structure, material resilience, and precise product support capabilities cater to challenging processing needs.

- Food Processing: For washing, drying, baking, freezing, cooling, and blanching. Belts made from 304 or 316L SS are ideal due to their hygiene, non-contaminating properties, and ease of cleaning. E.g., conveying pastries through baking ovens, freezing vegetables, or drying snacks.

- Heat Treatment: Used in annealing, brazing, sintering, quenching, and tempering furnaces. 310S SS is preferred for its high-temperature strength and oxidation resistance. E.g., carrying metal parts through continuous annealing furnaces, or glass items through lehr ovens.

- Glass & Ceramics: Essential for annealing, decorating, and firing processes. The smooth, flat surface ensures product stability and prevents marking.

- Chemical & Pharmaceutical: In washing, drying, or conveying products exposed to corrosive agents. 316L SS offers superior resistance to chemical attack. E.g., conveying chemicals through cleaning baths, or pharmaceutical products through sterile drying chambers.

- Electronics: For soldering, drying, and conveying delicate electronic components. Precise mesh apertures ensure stable transport of small parts.

- Automotive: Parts washing, heat treating, and conveying components during manufacturing.

- Recycling & Waste Management: For sorting, washing, and drying various materials, benefiting from robust construction and drainage capabilities.

Each application leverages specific characteristics of the wire conveyor belt, whether it's the open mesh for draining liquids, the heat resistance for thermal processes, or the smooth surface for delicate product handling.

Technical Advantages and Performance Enhancements

The inherent design and material properties of our wire mesh conveyor belts offer a multitude of technical advantages that contribute to enhanced operational performance and cost efficiency.

- Exceptional Temperature Resistance: Utilizing stainless steel grades like 310S allows continuous operation at temperatures up to 1150°C (2100°F), making them ideal for high-temperature furnace applications such as brazing, sintering, and annealing.

- Superior Corrosion Resistance: Materials such as 316L stainless steel provide robust protection against harsh chemicals, acids, and saline environments, significantly extending belt life in petrochemical, pharmaceutical, and water supply & drainage sectors.

- Optimized Airflow and Drainage: The open mesh structure facilitates efficient circulation of air or liquids, crucial for drying, cooling, washing, and freezing processes. This ensures uniform product treatment and reduces energy consumption by minimizing heat/cold loss.

- High Strength-to-Weight Ratio: Engineered weave patterns and material selections provide high tensile strength and load-bearing capabilities while maintaining a relatively low weight, reducing power requirements for the drive system and minimizing overall system strain.

- Easy to Clean and Maintain: The smooth, non-porous surface of stainless steel and the open design prevent product accumulation and allow for thorough wash-downs, meeting stringent hygiene standards. This reduces maintenance downtime and ensures product purity.

- Durability and Longevity: Built to withstand abrasive conditions and mechanical stresses, these belts offer extended service life, reducing the frequency of replacements and contributing to lower total cost of ownership.

- Product Stability and Precision: Uniform mesh opening and flat surfaces ensure stable transport of even small or irregularly shaped items, crucial for delicate product handling in electronics or glass manufacturing.

These advantages collectively translate into measurable benefits for our clients, including reduced operational costs, increased throughput, and enhanced product quality, solidifying the value proposition of high-performance mesh conveyor belt systems.

Vendor Comparison Considerations for Wire Conveyor Belts

Selecting the right supplier for wire conveyor belt systems is as critical as choosing the belt itself. Decision-makers should evaluate vendors based on several key criteria to ensure long-term value and operational reliability.

- Technical Expertise and R&D: A reputable vendor should demonstrate deep knowledge of material science, mechanical engineering, and specific industry applications. Look for evidence of ongoing R&D and innovative solutions to complex conveying challenges.

- Customization Capabilities: The ability to design and manufacture bespoke wire mesh belts tailored to unique dimensions, temperatures, loads, and environmental conditions is crucial. This includes variations in wire diameter, pitch, weave pattern, and edge configurations.

- Quality Assurance and Certifications: Verify that the vendor adheres to international quality management standards (e.g., ISO 9001) and material specifications (e.g., ASTM, ANSI). Certifications for specific industries (e.g., FDA compliance for food-grade belts) are also vital.

- Experience and Track Record: Longevity in the industry, a strong portfolio of successful projects, and positive customer feedback are indicators of reliability and proven performance.

- After-Sales Support and Warranty: Comprehensive warranty policies, readily available spare parts, and responsive technical support are essential for minimizing downtime and ensuring smooth operation throughout the belt's lifecycle.

- Cost-Effectiveness vs. Price: While initial cost is a factor, prioritize the total cost of ownership (TCO), which includes durability, energy efficiency, maintenance requirements, and potential for reduced downtime. A higher upfront investment in a superior wire mesh conveyor belts can yield significant long-term savings.

By thoroughly evaluating these factors, businesses can forge partnerships with suppliers who provide not just products, but holistic, reliable, and expertly supported conveying solutions.

Customized Solutions and Engineering Partnership

Recognizing that no two industrial applications are identical, we specialize in delivering highly customized wire mesh conveyor belts. Our engineering team works in close collaboration with clients to translate unique operational challenges into precisely engineered solutions.

Key Aspects of Our Customization Process:

- Material Optimization: Advising on the optimal stainless steel grade (201, 304, 316L, 310S) or specialized alloy based on temperature, corrosion, and load requirements.

- Design Modifications: Adapting belt dimensions (width, length), wire diameter, spiral and rod pitch to achieve desired open area, strength, and product support.

- Specialized Weave Patterns: Developing unique weave constructions (e.g., balanced weave, rod-reinforced, compound weave, conventional) to meet specific performance criteria like minimal elongation, enhanced product stability, or precise aperture size.

- Integrated Components: Incorporating flights, side guards, or special attachments directly into the belt design for precise product positioning, elevation, or containment.

- Edge Treatment Variations: Offering a range of edge finishes (e.g., welded, knuckled, plate edge, chain-driven) to ensure durability, prevent snagging, and maintain belt tracking.

- Engineering Consultation: Providing expert consultation during the design phase, including Finite Element Analysis (FEA) where necessary, to predict belt performance under specific load and environmental conditions, ensuring structural integrity and longevity.

This partnership approach ensures that each mesh conveyor belt is not just a component, but a perfectly integrated solution that enhances the overall efficiency and reliability of the client's production line.

Application Case Studies

Our experience in diverse industrial sectors has resulted in numerous successful deployments of custom wire mesh conveyor belts. Here are a few illustrative examples:

Case Study 1: High-Temperature Annealing Furnace

- Client: Leading Automotive Parts Manufacturer

- Challenge: Existing belts failed prematurely in continuous annealing furnaces operating at 1000°C (1832°F), leading to frequent downtime and high replacement costs.

- Solution: Engineered a robust wire mesh conveyor belts using 310S Stainless Steel with a custom, heavy-duty rod-reinforced balanced weave. The belt was designed to handle specific part geometries and weights without deformation.

- Outcome: Increased belt service life by over 300%, significantly reducing maintenance cycles and improving furnace throughput. The client reported enhanced product consistency due to stable conveying.

Case Study 2: Seafood Processing Wash-Down Line

- Client: Major Seafood Processing Plant

- Challenge: Required a hygienic and corrosion-resistant belt for washing, steaming, and cooling seafood, with exposure to saltwater and aggressive cleaning agents. Product adhesion was also a concern.

- Solution: Provided a 316L Stainless Steel wire mesh belt with a tight, smooth flat-wire weave to minimize product adhesion and ensure thorough drainage. The design facilitated quick and effective high-pressure wash-downs.

- Outcome: Achieved superior hygiene standards, reduced water consumption during cleaning, and eliminated belt corrosion issues. The client noted a significant improvement in operational uptime and product quality.

Case Study 3: Petrochemical Catalyst Drying

- Client: Global Petrochemical Corporation

- Challenge: Needed a highly durable and chemically resistant belt for conveying active catalysts through a drying oven, where particulate shedding and chemical interaction were critical concerns.

- Solution: Developed a specialized 316L wire mesh belt with an optimized open area for maximum airflow and minimal particle entrapment. The manufacturing process included enhanced passivation to fortify corrosion resistance.

- Outcome: The belt demonstrated exceptional longevity and maintained structural integrity under continuous chemical exposure and high temperatures. Product contamination was virtually eliminated, leading to higher quality catalyst production.

These case studies exemplify our commitment to providing tailored, high-performance wire conveyor belt solutions that address specific industrial demands and deliver tangible operational improvements.

Frequently Asked Questions (FAQ)

Q1: How do I select the correct material for my wire mesh conveyor belt?

A1: Material selection primarily depends on your operating temperature, the corrosiveness of the environment, and the mechanical loads. 304 SS is good for general use, 316L for high corrosion, and 310S for extreme high temperatures (up to 1150°C). Our technical team can assist in making the optimal choice based on your specific application parameters.

Q2: What is the typical lead time for a custom wire mesh belt?

A2: Lead times vary based on complexity, material availability, and current production schedules. Standard configurations typically range from 3-5 weeks, while highly customized or large-volume orders may require 6-10 weeks. We provide a detailed lead time estimate upon quotation.

Q3: Do your wire mesh conveyor belts come with a warranty?

A3: Yes, all our wire mesh belts are covered by a comprehensive warranty against manufacturing defects. The specific terms and duration depend on the product type and application, typically ranging from 12 to 24 months. Please refer to your sales agreement for precise warranty details.

Q4: What kind of after-sales support do you provide?

A4: We offer extensive after-sales support, including technical consultation, troubleshooting guides, spare parts supply, and, if necessary, on-site service. Our dedicated support team is available to assist with any operational queries or maintenance needs to ensure the longevity and optimal performance of your stainless steel wire mesh conveyor belt.

Lead Time, Fulfillment, and Warranty Commitments

We understand that timely delivery and reliable post-purchase support are crucial for our B2B partners. Our commitment to excellence extends beyond product quality to ensure a seamless client experience.

Lead Time & Fulfillment:

Our manufacturing processes are streamlined to optimize production and delivery. For standard wire mesh conveyor belts, typical lead times range from 3 to 5 weeks from order confirmation. Complex or highly customized solutions may require 6 to 10 weeks, depending on design intricacy and material availability. We employ robust logistics networks to ensure global fulfillment, providing transparent shipping updates throughout the process.

Warranty Commitments:

We stand by the quality and durability of our products. Each mesh conveyor belt is supplied with a standard warranty covering manufacturing defects and material integrity. The duration typically ranges from 12 to 24 months, contingent on the specific product configuration and its intended application. Detailed warranty terms are provided with every quotation and order confirmation, outlining covered aspects and conditions.

Customer Support:

Our dedicated customer support team is available to provide technical assistance, answer product queries, and facilitate any service needs. From initial consultation to post-installation support, we ensure our clients receive expert guidance and timely solutions. This commitment to ongoing support minimizes operational disruptions and maximizes the lifespan of your industrial investments.

Conclusion

The strategic selection and deployment of high-quality wire mesh conveyor belts are pivotal for optimizing industrial processing lines. By combining advanced material science with precision engineering, these essential components deliver unparalleled performance in challenging environments. From enhancing energy efficiency and resisting corrosion to ensuring precise product handling and extending service life, the benefits of robust wire conveyor belt systems are evident across a multitude of applications. Partnering with a specialist vendor capable of providing customized solutions, backed by rigorous quality assurance and comprehensive after-sales support, ensures that your investment translates into sustained operational excellence and competitive advantage.

References

- ISO 9001: Quality management systems. International Organization for Standardization.

- ASTM International Standards. (Various standards for stainless steel materials and mechanical testing).

- ASM Handbook, Vol. 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International.

- Food and Drug Administration (FDA) Regulations for food contact materials. U.S. Department of Health and Human Services.

- Perry's Chemical Engineers' Handbook. McGraw-Hill Professional.

Latest News

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

-

Grating Plumbing: Durable & Efficient Drainage Solutions For Modern Infrastructure

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA