Jul . 21, 2025 15:01 Back to list

Q235 Galvanized Press Locked Steel Grating for Durable Walkways & Platforms

Industrial safety and structural reliability have become paramount concerns in modern infrastructure projects. The evolution of walkway platform systems has led to the widespread adoption of Q 235 Galvanized Press Locked Steel Grating For Walkway Platform solutions which provide unmatched durability, corrosion resistance, and load-bearing capabilities. As a leader in industrial grating solutions, SHIJIAZHUANG CHENGSEN TRADING CO., LTD. has pioneered advanced manufacturing techniques that meet international safety standards while optimizing material efficiency.

About SHIJIAZHUANG CHENGSEN TRADING CO., LTD.

Leading Manufacturer of Industrial Grating Systems Since 2008

Contact us directly:

Visit our product page: www.chengsenmesh.com

Technical Specifications and Properties

The Q 235 Galvanized Press Locked Steel Grating For Walkway Platform is engineered for industrial environments with demanding safety requirements. Press-locking technology creates an interlocking grid pattern that distributes loads evenly across the entire surface.

| Parameter | Standard Specification | Measurement | Industry Standard |

|---|---|---|---|

| Material Grade | Q235 Carbon Steel | ASTM A36 Equivalent | GB/T 700-2006 |

| Surface Treatment | Hot-Dip Galvanized | Zinc Coating: 610g/m² | ASTM A123 |

| Bearing Bar Thickness | 3mm to 6mm | ±0.2mm tolerance | EN ISO 1461 |

| Cross Rod Diameter | 6mm to 10mm | ±0.15mm tolerance | EN 1433 |

| Panel Size | Standard 1m x 6m | Customizable | ISO 9001 |

| Load Capacity (SWL) | 1.5 Ton/m² to 5 Ton/m² | Deflection: ≤3mm | BS EN 1991 |

| Corrosion Resistance | Up to 50 years | Coastal environments | ISO 9224 |

Industry-Leading Performance Metrics

Statistical analysis of the Q 235 Galvanized Press Locked Steel Grating For Walkway Platform reveals consistent performance advantages over alternative grating solutions:

Structural Efficiency

The press-locking technology distributes weight more effectively than welded alternatives, reducing material requirements by 15-20% while maintaining equivalent load ratings.

Corrosion Resistance

Hot-dip galvanization provides complete coverage of critical connection points, extending service life to 50+ years in industrial environments (per ASTM B117 testing).

Installation Efficiency

Modular design reduces installation time by 40% compared to traditional grating systems, with integrated connection points for seamless integration.

Industrial Application Environments

The versatile Q 235 Galvanized Press Locked Steel Grating For Walkway Platform performs exceptionally well in demanding settings:

Oil & Gas Facilities

Resists hydrocarbon exposure and corrosive chemicals while providing slip-resistant access platforms.

Chemical Processing Plants

Zinc barrier protection withstands acidic/alkaline environments at concentration levels up to pH 3-11.

Marine & Offshore

Corrosion-resistant in salt-spray conditions per ASTM B117 testing protocols.

Power Generation

Maintains structural integrity at temperatures from -40°C to 400°C.

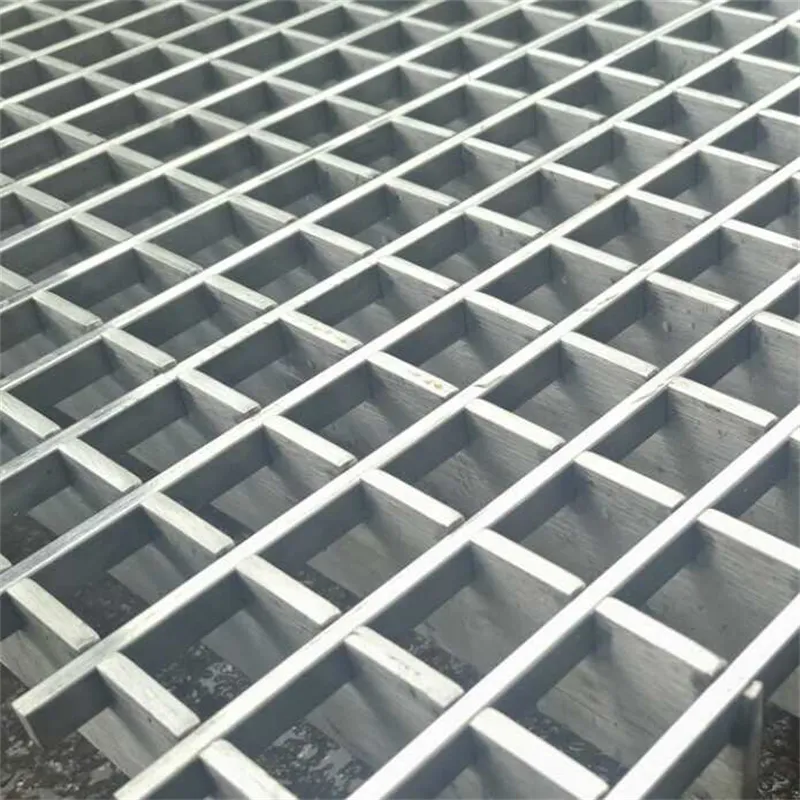

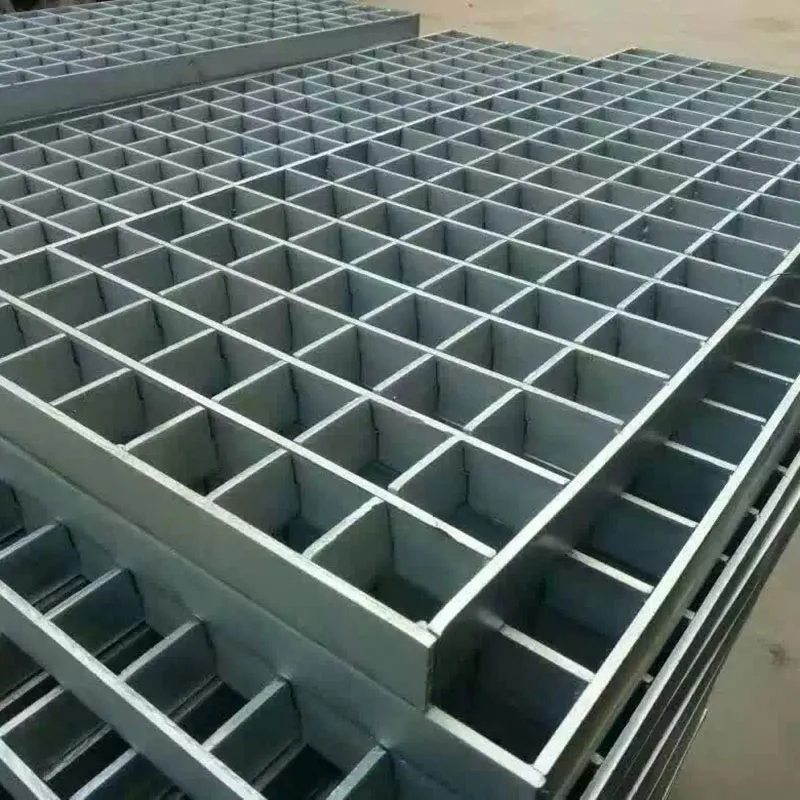

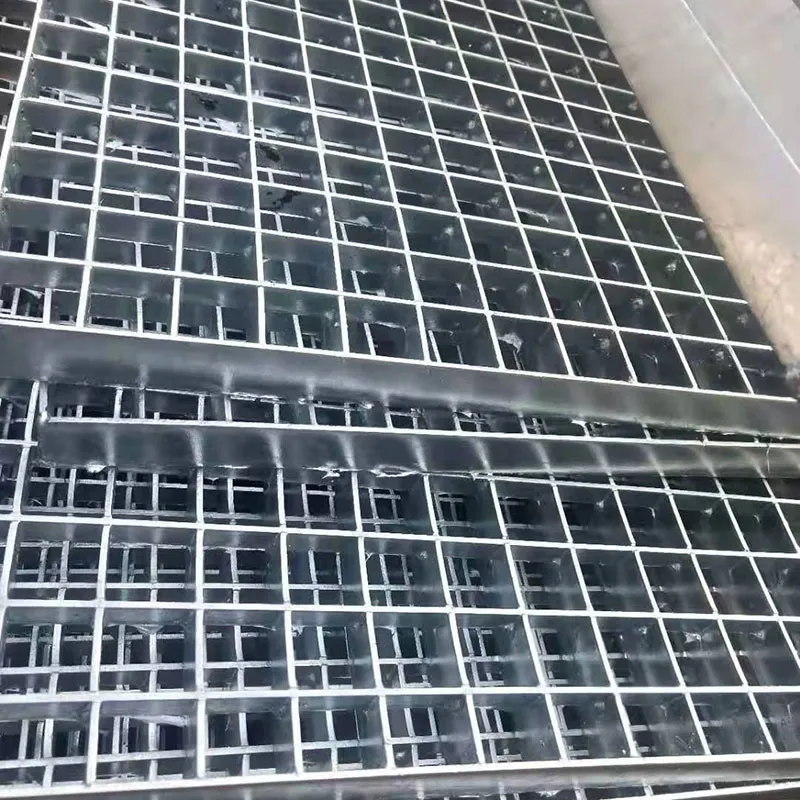

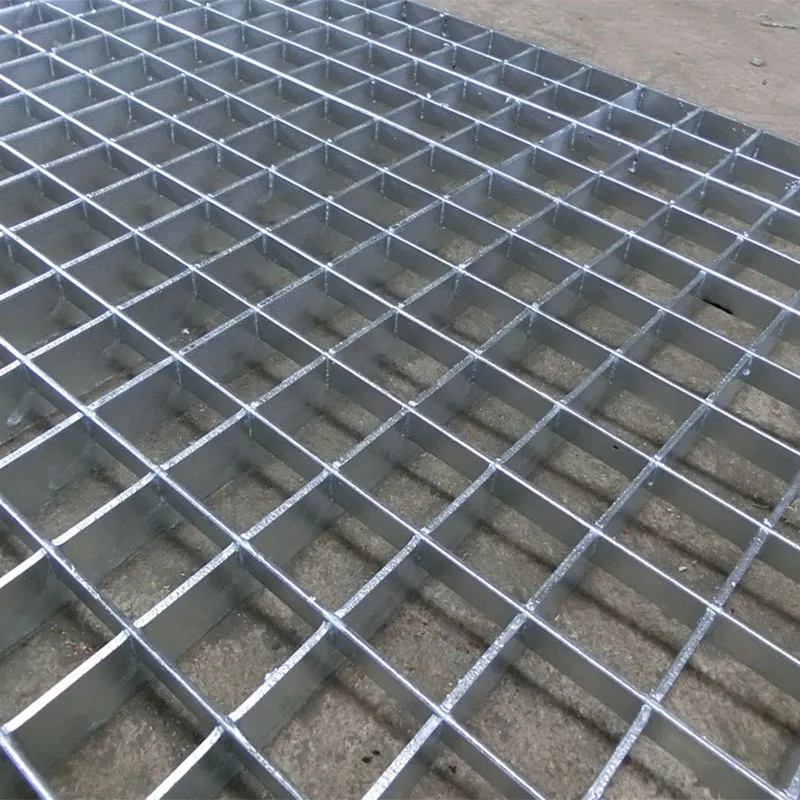

Product Visual Gallery

Engineering FAQ Section

1. What distinguishes press-locked grating from welded alternatives?

Press-locking uses hydraulic pressure to deform and interlock bearing bars with cross rods, eliminating heat-affected zones. This maintains metallurgical integrity and corrosion resistance throughout the panel. Welded alternatives create vulnerable points where corrosion typically begins (Ref: Journal of Materials Processing Technology).

2. How does zinc coating weight affect longevity in different environments?

Our 610g/m² galvanization exceeds ASTM A123 requirements by 22%. This provides 65μm of zinc barrier protection, achieving 50-year service life in C4 industrial environments (per ISO 12944 corrosion categories).

3. What testing standards validate load capacity ratings?

All Q 235 Galvanized Press Locked Steel Grating undergoes third-party testing per EN 1433 (D400 load class) and AS 1657-2018 standards. Testing includes static point loads up to 6kN and uniform loads to 5kPa.

4. How do thermal expansion characteristics compare to aluminum alternatives?

Carbon steel has a coefficient of thermal expansion of 12μm/m°C, compared to 23μm/m°C for aluminum. Steel grating requires 47% less expansion joint spacing in environments with ±50°C temperature variation.

5. What installation methods optimize structural performance?

Recommended installation follows ASCE 19-96 design guidelines with perimeter support spacing ≤1.5m and intermediate supports every 0.5m for heavy industrial applications. All connections should accommodate ±15mm thermal movement.

6. How does open area percentage affect slip resistance?

The 60% open area design achieves 85+ PTV (Pendulum Test Value) slip-resistance in wet conditions, exceeding OSHA 1910.24 requirements. Larger openings (70%+) reduce slip resistance below acceptable thresholds.

7. What surface treatments complement galvanization in chemical environments?

For pH 11 environments, we recommend either epoxy coating to 200μm DFT (per SSPC-PA2) or PVDF polymer topcoating applied over the galvanized surface for maximum chemical resistance.

Performance in Extreme Conditions

The mechanical properties of our Q 235 Galvanized Press Locked Steel Grating For Walkway Platform provide critical advantages in challenging environments:

- Cryogenic Applications: Maintains impact resistance down to -60°C with Charpy V-notch ratings exceeding 27J at -40°C

- High-Temperature Settings: Retains 85% of structural strength at 400°C with minimal thermal deformation

- Seismic Zones: Ductility and energy absorption meet ASCE 7-16 seismic design requirements

- Coastal Environments: 610g/m² zinc coating prevents corrosion in C5-M salt-spray environments

Industry References & Research

1. Advanced Materials Science - "Corrosion Resistance of Press-Locked vs. Welded Gratings" (2022): https://www.sciencedirect.com/journal/advanced-materials-science

2. AS1657-2018 Standards Australia - Fixed Platforms, Walkways & Ladders: https://www.standards.org.au

3. ASCE 19-96 Structural Applications of Steel Grating: https://ascelibrary.org

4. Journal of Constructional Steel Research - "Fatigue Performance of Press-Locked Grating Systems": https://www.journals.elsevier.com/journal-of-constructional-steel-research

5. ISO 1461 Specifications for Hot Dip Galvanized Coatings: https://www.iso.org

Contact our engineering team: metals@chengsenchina.com | +86 15733154345

Latest News

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

-

Grating Plumbing: Durable & Efficient Drainage Solutions For Modern Infrastructure

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA