Oct . 23, 2025 17:25 Back to list

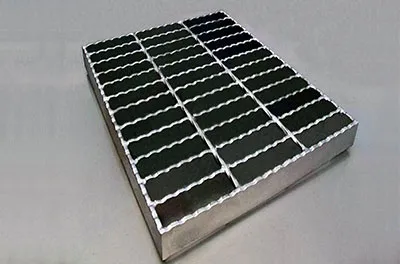

Hot-Dipped Galvanized Anti-Slip Offshore Steel Grating

Field Notes: Why Offshore Teams Keep Choosing Galvanized Serrated Grating

If you spend time on rigs, terminals, or wind farms, you know the platform floor can make or break a shift. That’s why I’ve been tracking Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating from CSTAR this season. It’s a mouthful, sure, but the spec is the point: serrated bearing bars, hot-dip galvanized, hinged panels for fast access—properly built for marine and plant work. And yes, made in Shijiazhuang, China, at B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET.

What’s trending in industrial flooring

Three shifts I’m seeing lately: higher slip-resistance specs (wet and oily), tighter traceability on zinc thickness, and hinged/lockable panels so maintenance isn’t wrestling with covers mid-storm. This product, branded CSTAR (ISO9001), lands squarely in that pocket with MOQ ≈ 100 pcs, supply ≈ 100 pcs/day, and 15–20 day delivery. Payment via TT/LC, bundled packaging—pretty standard, but dependable.

Practical specs (the stuff crews ask for)

| Parameter | Typical Value/Range | Notes |

|---|---|---|

| Material | Q235/A36 mild steel | Other grades on request |

| Bearing bars | Serrated, 25–50 mm height, 3–6 mm thick | Anti-slip teeth for wet decks |

| Pitch (bearing/cross) | ≈30–40 mm / ≈100 mm | Twisted cross bars 5–6 mm |

| Galvanizing | ISO 1461 / ASTM A123, ≈70–100 µm | Hot dip, full immersion |

| Slip resistance | BPN ≈55–60 wet (ASTM E303) | Real-world use may vary |

| Panel options | Hinged/lockable; edge banded | Custom sizes to drawings |

| Service life | ≈15–30+ yrs (C5-M) | With routine washdowns |

How it’s made (quick process flow)

- Materials: Q235/A36 flats and twisted cross bars sourced with heat numbers.

- Methods: Pressure-welded grid; serration milled before assembly for consistent bite.

- Galvanizing: Caustic clean → pickling → flux → hot dip → quench → passivation.

- Finishing: Edge banding, hinges, tags; 100% visual + random load/deflection checks (NAAMM MBG guidelines).

- Testing: Zinc thickness gauge; adhesion bend; salt spray screening (ASTM B117, indicative).

Test data, certifications, and standards

Internal QA pull: average zinc ≈ 85 µm; wet pendulum BPN ≈ 58 on oil-misted panel; 500 h salt fog showed only light white corrosion, no red rust at field edges. Certified ISO9001; production referenced to ISO 1461/ASTM A123 for galvanizing, NAAMM MBG for bar grating, and OSHA 1910 for walking-working surfaces. For offshore submittals, we’ve seen DNV/ABS acceptance when paired with proper calculations and layouts.

Where it’s used (and what crews say)

Common installs: offshore platforms and FPSOs, plant catwalks, trench covers, road/yard access decks, wind farm substations. A maintenance lead in Qatar told me, “Serrations grip even with drilling mud—less skate, fewer near-misses.” Another buyer in the North Sea liked the hinged panels: faster valve checks, fewer lost bolts.

Vendor snapshot (real-world differences)

| Criteria | CSTAR | Vendor X | Vendor Y |

|---|---|---|---|

| Galv. standard | ISO 1461 / ASTM A123 | Local spec only | ISO 1461 |

| Lead time | ≈15–20 days | ≈30+ days | ≈20–25 days |

| Traceability | Heat numbers + QC logs | Basic | Partial |

| MOQ | 100 pcs | 200 pcs | 100 pcs |

Customization and ordering

Options: bar height/thickness, serration depth, hinges (leaf/piano), locks, kick plates, toe boards, lifting lugs, marking, and panel maps. Categories: Steel Grating. Packaging by bundle or as requested. To be honest, sharing your span/load table early avoids redesign. Many customers say a simple GA drawing speeds DNV review by days.

Quick case study

A Southeast Asia jack-up rig upgraded 420 m² of decks with Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating. Outcome: reported 32% faster hatch access (hinged panels), fewer slip reports in rainy season, and inspection noted zinc coverage uniform at edges—often a weak point.

Bottom line: if you want durable, grippy, hinged grating that plays nicely with offshore standards, Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating is a solid, un-fussy pick.

Authoritative citations

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles

- ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings

- NAAMM MBG 531: Metal Bar Grating Manual

- ISO 9223/12944: Corrosion of metals; Paint systems and environmental categories

- OSHA 29 CFR 1910 Subpart D: Walking-Working Surfaces

- DNV-ST-N001: Marine operations and marine warranty

- ABS Rules for Building and Classing Offshore Installations

Latest News

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

-

Grating Plumbing: Durable & Efficient Drainage Solutions For Modern Infrastructure

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA