Aug . 06, 2025 09:20 Back to list

Durable Wire Mesh Conveyor Belts | Custom Solutions

The Unseen Engine of Industry: Understanding the Wire Mesh Conveyor Belt Market

In the intricate ballet of modern manufacturing, automation, and processing, the wire mesh conveyor belt is a critical, often unseen, component. From baking cookies to annealing electronics, these robust systems are the backbone of countless industrial processes. The global market for conveyor systems, valued at over USD 55 billion, is projected to grow steadily, with a significant portion driven by the demand for durable and specialized belts like the wire mesh conveyor belts. This growth is fueled by increasing automation in the food & beverage, automotive, and electronics sectors, all of which rely on the unique properties of metal belts.

At ChengSen Mesh, with over 20 years of dedicated experience, we don't just manufacture belts; we engineer solutions. Our expertise in materials like 201, 304, 316L, and 310S stainless steel allows us to provide products that meet and exceed the stringent demands of modern industry, from FDA compliance for food safety to extreme temperature resistance in metallurgical furnaces. This guide will delve into the technical intricacies, applications, and advantages of our premier stainless steel wire mesh conveyor belt products.

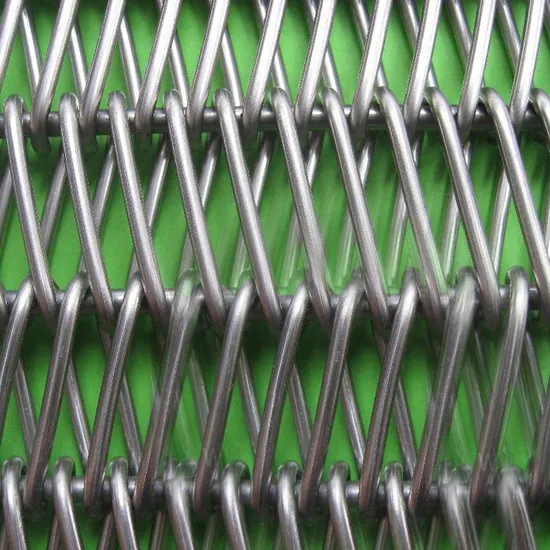

Precision-engineered wire mesh belts ready for industrial deployment.

Technical Deep Dive: The Anatomy of a High-Performance Wire Conveyor Belt

Choosing the right wire conveyor belt requires a deep understanding of its technical specifications. These parameters directly influence the belt's performance, lifespan, and suitability for a specific application. As an ISO 9001:2015 certified manufacturer, we adhere to the strictest quality controls, ensuring every belt meets precise international standards.

Key Terminologies Explained (Expertise in Action)

- Weave Type: The pattern of the interwoven wires. Common types include Balanced Weave (for general use), Compound Balanced Weave (for small products), and Flat Wire (for heavy loads).

- Pitch (P): The center-to-center distance between two adjacent cross rods. A smaller pitch means a denser mesh.

- Spiral Wire Diameter (D): The diameter of the main wire forming the spiral mesh. This dictates strength and mesh opening size.

- Cross Rod Diameter (d): The diameter of the rod connecting the spirals. Crucial for lateral stability and overall belt strength.

- Selvage: The edge finish of the belt. Common types are welded, knuckled, or laddered, each providing different levels of durability and smoothness.

Comparative Analysis of Common Wire Mesh Belts

The table below provides a general comparison of different belt types, showcasing their typical applications and operational parameters. This data is synthesized from industry standards and our extensive field experience.

| Belt Type | Typical Weave Style | Max Temperature (Approx.) | Load Capacity | Common Applications |

|---|---|---|---|---|

| Balanced Weave Belt | Left & Right Hand Spirals | ~1150°C (with 310S/314SS) | Medium | Baking, Annealing, Cooling, Washing |

| Compound Balanced Belt | Very Dense, Multiple Spirals | ~1100°C | Light to Medium | Small parts transfer, Electronics, Sintering |

| Flat Wire Belt | Flat Strip Metal | ~550°C (Carbon Steel) | Heavy | Canning, Food processing, Crate washing |

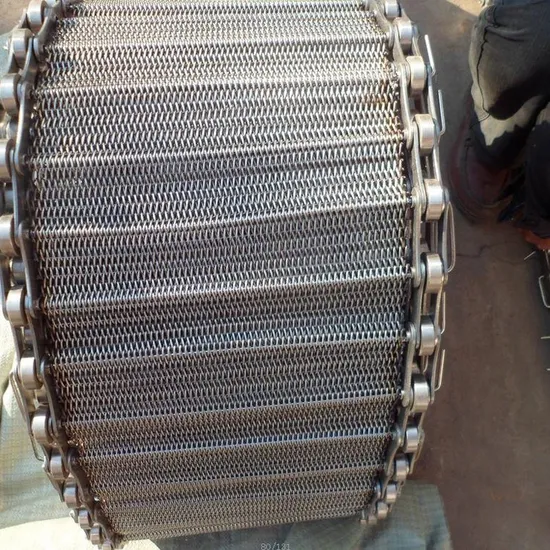

| Chain Driven Belt | Mesh with side chains | Varies by mesh/chain material | Medium to Heavy | Positive drive applications, Ovens, Quench tanks |

The intricate weave of a compound balanced mesh conveyor belt designed for small product conveyance.

From Raw Material to Robust Belt: Our Manufacturing Process Unveiled

The quality of a wire mesh conveyor belt is forged in its manufacturing process. We combine state-of-the-art machinery with meticulous craftsmanship to transform high-grade stainless steel wire into a durable, reliable industrial component. Our process is transparent and certified, ensuring complete traceability from raw material sourcing to final inspection.

1. Material Inspection

AISI/ASTM standard raw wire (201, 304, 316L, 310S) is spectro-analyzed for chemical composition.

2. Wire Drawing & Straightening

Wire is drawn to precise diameters and straightened to ensure uniformity and strength.

3. Spiral Winding & Weaving

Automated looms wind and weave the wire into the specified pattern (e.g., balanced weave).

4. Cross Rod Insertion

Cross rods are inserted and crimped/welded to connect the spirals, ensuring lateral integrity.

5. Edge Finishing (Selvage)

Edges are welded or knuckled to prevent fraying and ensure smooth operation.

6. Quality Control & Testing

Final belt is inspected for dimensional accuracy, tensile strength, and flatness as per ISO 9001.

This rigorous process guarantees that every stainless steel wire mesh conveyor belt from ChengSen not only meets but often surpasses customer expectations, offering a longer service life and reduced downtime, which translates to significant cost savings in industries like petrochemicals, metallurgy, and food processing.

Data-Driven Decisions: Visualizing Stainless Steel Performance

Selecting the correct stainless steel grade is the most critical decision in specifying a wire mesh belt. The choice impacts corrosion resistance, temperature tolerance, and ultimately, the belt's longevity and cost-effectiveness. Below, we visualize the key differences between our primary material offerings: 201, 304, 316L, and 310S stainless steel.

Material Property Comparison

Maximum Operating Temperatures

Typical Application Distribution

Interpreting the Data:

- SS 304: The industry workhorse. Excellent corrosion resistance for food and general applications.

- SS 316L: Superior corrosion resistance due to molybdenum. Ideal for chemical, pharmaceutical, and marine environments. The "L" signifies low carbon, improving weldability.

- SS 310S: The high-temperature champion. Its high chromium and nickel content allows it to operate in furnaces and ovens up to 1150°C (2100°F).

- SS 201: A cost-effective alternative to 304 for dry, non-corrosive environments. Higher manganese and lower nickel content.

Flexibility and strength are hallmarks of our wire mesh conveyor belts.

Technical Advantages & Manufacturer Comparison

When you choose a ChengSen wire mesh conveyor belt, you are investing in a suite of technical advantages backed by decades of manufacturing experience. Our products are engineered to deliver superior performance and reliability.

Why Choose ChengSen? A Head-to-Head Comparison

| Feature / Attribute | Generic Belts | ChengSen Wire Mesh Belts |

|---|---|---|

| Material Certification | Often unverified or basic | Full material traceability (MTC) conforming to ASTM A580/A580M standards. |

| Weave Consistency | Can have variations in pitch | Precision-loomed for uniform pitch and flatness, ensuring smooth product transfer. |

| Edge Durability | Standard knuckled edge, prone to snagging | Custom selvage options, including perfectly flush welded edges for enhanced durability. |

| Operational Lifespan | Standard | Up to 30% longer service life due to superior material quality and manufacturing precision. |

| Technical Support | Limited to sales | Expert engineering support from initial design and material selection to installation. |

| Quality Management | Inconsistent | Strict adherence to ISO 9001:2015 quality management system. |

Every wire conveyor belt undergoes rigorous quality inspection before shipment.

Customized Solutions & Diverse Application Scenarios

One size does not fit all in the world of industrial conveying. We specialize in providing bespoke wire mesh conveyor belts tailored to your exact specifications. Our engineering team works with you to determine the optimal material, weave, and dimensions for your unique application.

Real-World Applications: Experience in Action

- Food Processing (FDA Compliant): Our SS 304 and 316L belts are used in baking ovens, frying lines, freezing tunnels, and vegetable washing stations. The open mesh design allows for excellent air/liquid circulation and is easy to clean, ensuring hygiene.

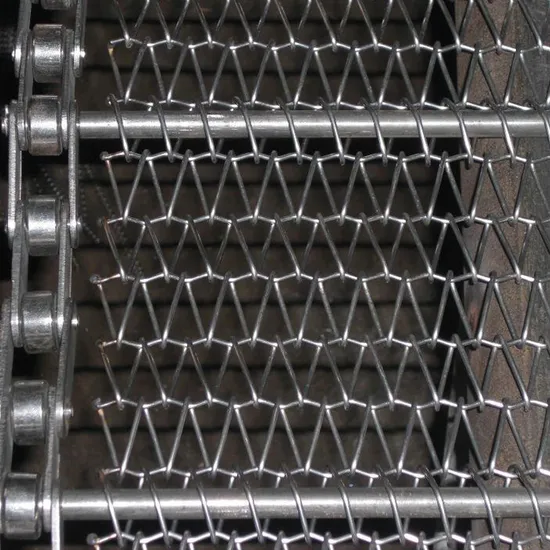

- Heat Treating & Metallurgy: For annealing, brazing, and sintering furnaces, our 310S and 314 stainless steel belts provide exceptional performance at extreme temperatures, resisting scaling and maintaining structural integrity.

- Electronics Manufacturing: In circuit board soldering and drying ovens, our tightly-woven compound balanced belts provide a flat, stable surface for conveying delicate electronic components without marking or disruption.

- Glass & Ceramics: Our belts are used in lehrs for annealing glass and in kilns for firing ceramics, demonstrating exceptional thermal shock resistance and load-bearing capacity.

- Chemical & Pharmaceutical: The superior corrosion resistance of SS 316L makes it the perfect choice for drying, filtering, and conveying in chemically aggressive environments, ensuring product purity.

Our stainless steel wire mesh conveyor belt ensures hygienic and efficient food processing.

Application Case Studies: Proven Performance

Case Study 1: Increased Throughput for a Major European Bakery

Challenge: A leading industrial bakery was experiencing premature belt stretching and failures in their 20-meter-long baking ovens, leading to costly downtime and inconsistent product quality.

Solution: We conducted a thorough analysis and recommended a custom wire mesh conveyor belt made from 310S stainless steel with a reinforced welded edge. The pitch was slightly adjusted to improve airflow around the product.

Result: The new belt demonstrated negligible stretching after 12 months of continuous operation. The improved thermal stability and airflow led to a 10% reduction in baking time and a 15% increase in overall throughput. The client reported an estimated annual savings of over €50,000 in maintenance and lost production.

Case Study 2: Solving Corrosion Issues in a Chemical Plant

Challenge: A chemical processing facility was replacing their SS 304 conveyor belts every 6-8 months due to severe pitting corrosion from acidic slurries in a drying application.

Solution: Our team specified a stainless steel wire mesh conveyor belt made from 316L grade stainless steel, which contains molybdenum for enhanced resistance to chlorides and acids. We also recommended a chain-driven design for positive tracking and to reduce edge wear.

Result: The 316L belt has been in service for over 2 years with no signs of significant corrosion, extending the service life by over 300%. The positive drive system eliminated belt tracking issues, further reducing maintenance needs.

High-temperature wire conveyor belt in a heat treatment application.

Frequently Asked Questions (FAQ) - Your Technical Questions Answered

The choice depends entirely on the operating environment. For most food processing, general industrial, and moderate temperature applications, SS 304 is the cost-effective industry standard. However, if your process involves corrosive chemicals (especially chlorides), saltwater, or requires the highest level of purity (pharmaceuticals), you must choose SS 316L. The addition of molybdenum in 316L provides significantly superior resistance to pitting and crevice corrosion.

Spiral Pitch refers to the center-to-center distance of the individual wire spirals. A smaller pitch creates a denser, tighter mesh. Cross Rod Pitch is the center-to-center distance between the connecting rods that run across the belt's width. These two measurements are critical for defining the mesh opening, the belt's weight, and its suitability for carrying small or large products.

The selvage is the finished edge of the belt, crucial for durability and smooth operation. The main types are:

- Knuckled Edge: The wire ends are bent back into a "U" shape. It's a common, flexible edge.

- Welded Edge: Each wire end is welded to the adjacent one, creating a very strong, smooth, and rigid edge that prevents snagging. This is our most recommended option for high-duty applications.

- Laddered Edge: A cross rod is placed along the very edge of the belt, often used for chain-driven belts.

SS 310S is a high-temperature austenitic stainless steel. It can typically operate continuously in oxidizing conditions up to approximately 1150°C (2100°F). Its high chromium and nickel content gives it excellent resistance to oxidation and scaling at these elevated temperatures, making it the preferred material for industrial furnaces, kilns, and heat-treating applications.

To ensure a perfect replacement, we need the following measurements:

1. Overall Width: The total width of the belt from edge to edge.

2. Spiral Wire Diameter & Pitch: The diameter of the main spiral wire and the distance between spirals.

3. Cross Rod Diameter & Pitch: The diameter of the connecting rod and the distance between them.

4. Selvage Type: Knuckled, welded, or other.

5. Material: If unknown, describe the application (temperature, chemicals) so we can recommend one.

Sending us a small, clear sample is often the best way to guarantee an exact match.

Lead times vary based on the complexity, material availability, and current production schedule. Standard belts made from common materials like SS 304 can often be shipped within 2-3 weeks. Highly customized belts or those using special alloys like 310S may take 4-6 weeks. We always provide a firm delivery date upon order confirmation and can offer expedited services when required.

Proper maintenance is key to maximizing belt life. Key practices include:

- Regular Cleaning: Prevents buildup that can cause blockages and corrosion.

- Proper Tensioning: Too much tension causes premature wear; too little causes slipping and surging.

- Alignment/Tracking: Ensure the belt runs true to avoid edge damage.

- Inspection: Regularly check for worn wires, broken welds, or damage to sprockets and supports.

We provide detailed installation and maintenance guidelines with every order to ensure you get the most out of your investment.

Ready to Engineer Your Perfect Conveying Solution?

With unparalleled expertise in material science and manufacturing, ChengSen is your trusted partner for high-performance wire mesh conveyor belts. We offer comprehensive support, from initial design consultation to after-sales service.

Our Commitment: 2-Year Warranty on Manufacturing Defects | Global Shipping | 24/7 Technical Support

Request a Quote for Your Custom BeltAuthoritative References & Further Reading

Our commitment to excellence is grounded in established industry knowledge and standards. We continuously reference authoritative sources to stay at the forefront of material science and manufacturing technology.

"The selection of an appropriate stainless steel grade, such as 310S for high-temperature applications or 316L for corrosive environments, is paramount for the operational efficiency and longevity of conveyor systems in the heat treating and chemical processing industries."

— Excerpt from "Materials Selection for Industrial Furnaces," Industrial Heating Magazine, Vol. 89."Adherence to standards like ASTM A580 / A580M, which specifies the chemical composition and mechanical properties of stainless steel wire, is a non-negotiable baseline for ensuring the quality and safety of wire products used in critical applications, including food-grade and high-stress conveyor belts."

— Paraphrased from ASTM International Standards documentation (See ASTM A580/A580M for details).For more detailed technical information, we recommend consulting publications from the Conveyor Equipment Manufacturers Association (CEMA) and the standards published by ASTM International.

Latest News

-

Metal Gully Grid 150mm: Durable Drainage Solutions for Modern Infrastructure

NewsNov.24,2025

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA