Oct . 21, 2025 14:20 Back to list

Customized Round Steel Grid Ditch Cover for Sump/Drain, Safe

Round Ditch Covers Are Having a Moment — Here’s What’s Actually Behind the Trend

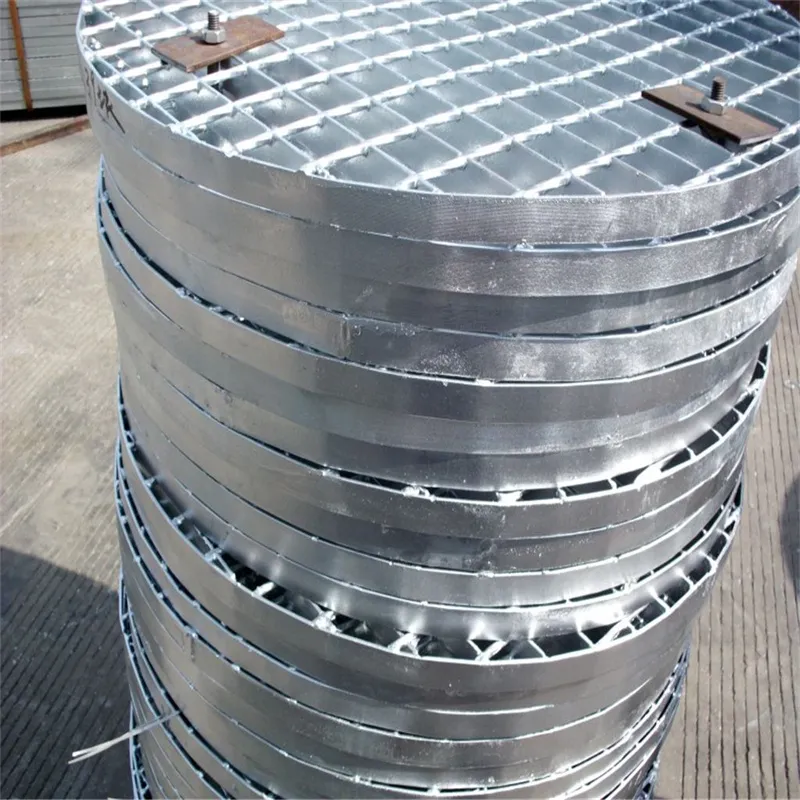

If you manage drainage or utility infrastructure, you’ve probably noticed the shift: more projects are requesting circular gratings with hinge pins and anti-slip serrations. I’ve been on sites where crews literally cheer when a lid flips open cleanly and stays put at about 110°. That’s why the Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain keeps popping up in bid specs. It’s not just fashion—there’s engineering logic here.

What It Is (and Where It Fits)

The GM-type round well-hole steel grating is designed for rainwater, sand, sewer, and sewage wells—plus vent holes and manholes in municipal roads, parks, plants, and waterfronts. The flip-up design (≈110° opening) with a hinge pin reduces theft risk and simplifies maintenance. Origin: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA. Many customers say the hinge saves two people per maintenance visit—small detail, big effect over a year.

Key Specs at a Glance

| Shape / Type | Round GM-type flip-up with hinge pin |

| Bearing Bar | Flat bar 25–50 mm depth × 3–5 mm thick; serrated optional |

| Pitch (c/c) | Bearing 30–40 mm; cross bar 50–100 mm (≈typical) |

| Diameter | 400–1200 mm (custom larger by request) |

| Steel Grade | Q235 / Q345 (≈ASTM A36), SS304/316 available |

| Coating | Hot-dip galvanized per ASTM A123 / ISO 1461; powder coat optional |

| Flip Angle | ≈110°, balanced opening with stop |

| Load Class | A15–D400 per EN 124-2 (real-world use may vary by span) |

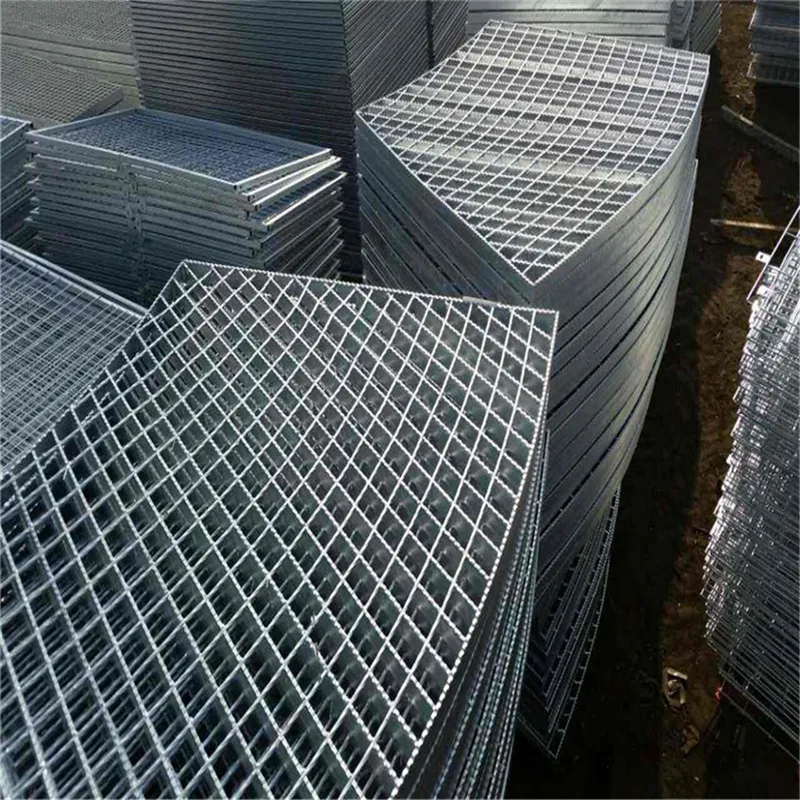

How It’s Made (Short Version)

Materials: carbon steel (Q235/Q345) or stainless (304/316). Methods: pressure-welded or forge-welded grating, then ring-rolled to round, hinge-pin integrated, fully deburred. Coating: hot-dip galvanizing (zinc ≈70–100 μm typical). Testing: load/deflection per EN 124-2 class targets; coating thickness per ISO 1461; slip-resistance (serrated bars) internal CoF ≈0.45–0.55 wet steel plate baseline. Service life: in C3–C4 urban atmospheres, galvanized systems often achieve 20–30 years with routine inspection.

Why Round? A Few Practical Advantages

- Won’t fall through its own frame—obvious but important.

- Even load distribution around the frame helps longevity.

- Flip-up hinge cuts retrieval time; reduces theft risk.

- Serrated bars improve traction—operators notice immediately.

Application scenarios: city streets (D400), pedestrian parks (A15–C250), treatment plants (chemical splash concerns favor SS316), logistics yards (C250–D400), and waterfront drains (check zinc thickness and seal welds). I guess the quiet win is maintenance safety—hinged lids mean fewer awkward lifts.

Real Projects, Real Feedback

Case study 1: Coastal park walkway—C250 class, serrated 30×5 mm bars, diameter 800 mm. After 12 months, zinc loss measured ≈8–10 μm; no hinge play. Crew said “surprisingly quiet under foot.”

Case study 2: Food factory sump—SS304, powder topcoat over passivation. Cleaning team likes the flip angle control; no accidental slams. Deflection under 25 kN test was

Vendor Snapshot (What to Ask Before You Buy)

| Vendor | Lead Time | Custom Shapes | Certs/Reports | Notes |

|---|---|---|---|---|

| Chengsen | ≈2–4 weeks | Round, oval, offset frames | EN 124 class report, ISO 1461 zinc | Hinged 110°, anti-slip serration |

| Vendor B | 3–6 weeks | Round only | Galv. thickness only | Economy pricing |

| Vendor C | 4–8 weeks | Round + rectangular | EN 124 only on request | Premium stainless focus |

Customization Pointers

Specify: diameter, span, target EN 124 class, bar depth/thickness, serration yes/no, hinge orientation, locking needs, corrosion category. For chemicals or brine, consider Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain in SS316; for urban streets, galvanized carbon steel is usually the value choice.

Certifications, Standards, and Data

Typical compliance: EN 124-2 load classes (A15–D400); hot-dip galvanizing to ASTM A123 / EN ISO 1461; grating design guidance aligned with BS 4592. Factory QC includes load/deflection checks, zinc thickness tests, weld integrity inspection, and fit of the 110° flip-up.

Many municipalities now insist on traceable test sheets. Ask for the batch zinc report and a witness load test—honestly, it’s a small ask that filters out weak frames.

Authoritative citations

- EN 124-2:2015 Gully tops and manhole tops for vehicular and pedestrian areas.

- ISO 1461:2009 Hot dip galvanized coatings on fabricated iron and steel articles.

- ASTM A123/A123M-17 Standard Specification for Zinc (Hot-Dip Galvanized) Coatings.

- BS 4592-0:2006+A1:2012 Industrial type flooring and stair treads — Metal open bar gratings.

Final thought: if your crew keeps asking for the Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain, it’s probably because it makes their day a little easier—and in maintenance, that’s half the battle.

Latest News

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

-

Grating Plumbing: Durable & Efficient Drainage Solutions For Modern Infrastructure

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA