Sep . 15, 2025 11:20 Back to list

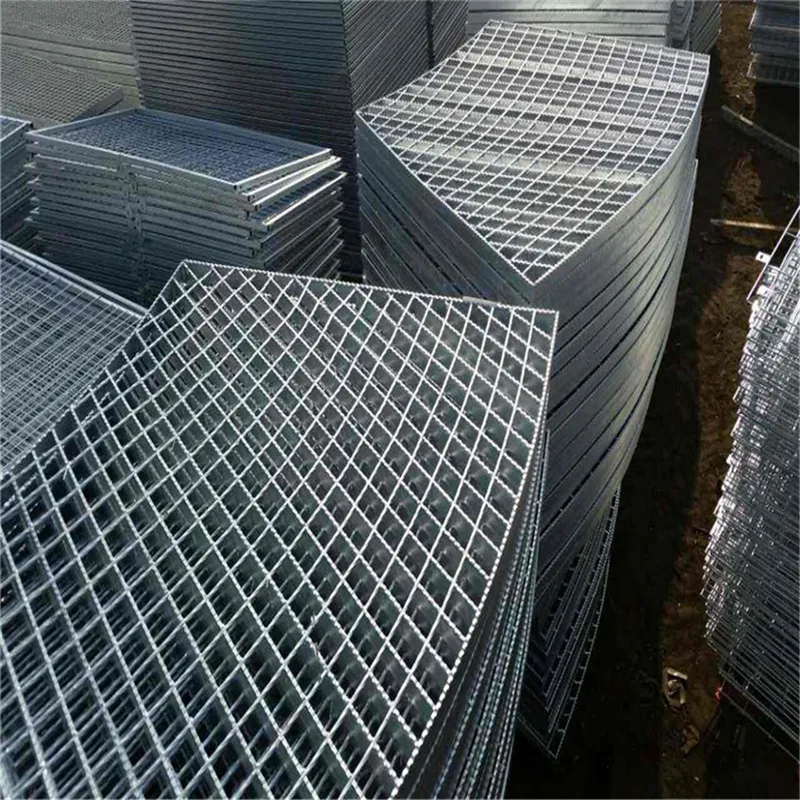

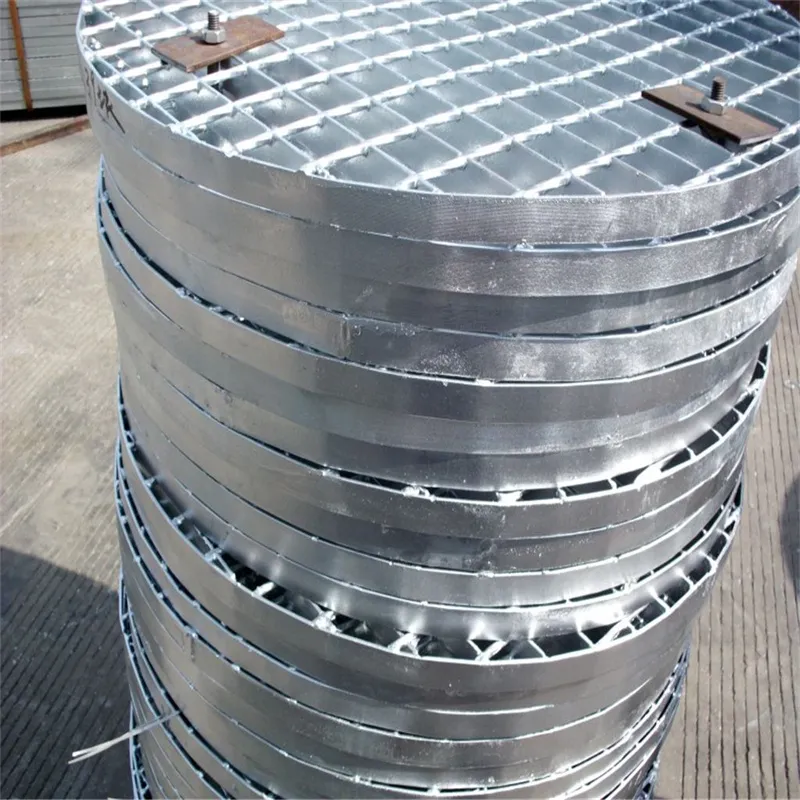

Custom Special Round Steel Grating Sump/Drain Cover & Ditch Grate

Introduction to Advanced Drainage Solutions

In industrial and municipal infrastructure, effective and durable drainage systems are paramount for operational efficiency and safety. Traditional drainage solutions often struggle with specific spatial requirements, heavy load-bearing demands, and corrosive environments. This necessitates specialized engineering, leading to the development of highly customized solutions. Our focus today is on the Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain, a robust and adaptable product engineered to meet the stringent demands of modern industrial applications.

This specialized grating is designed for optimal performance in sumps, drains, and other circular openings, providing superior strength, excellent drainage capacity, and long-term resistance to harsh conditions. Its customizable nature ensures a perfect fit and functional integration into diverse projects, from chemical processing plants to municipal water treatment facilities.

Industry Trends & Market Demands for Specialized Gratings

The industrial landscape is continuously evolving, driving demand for advanced infrastructure components. Key trends include an increasing focus on operational safety, environmental compliance, and the total cost of ownership (TCO) over the product lifecycle. This translates into a strong market pull for high-performance, durable, and low-maintenance drainage solutions. Specifically, the need for custom-fabricated gratings has surged due to:

- Complex Geometries: Modern industrial layouts often feature non-standard sumps and drains requiring bespoke circular or irregular gratings.

- Enhanced Load-Bearing: Growing industrial equipment sizes and vehicle traffic necessitate gratings capable of sustaining extreme loads, often exceeding standard specifications.

- Corrosion Resistance: Industries like petrochemicals, marine, and food processing demand materials and coatings that can withstand aggressive chemical exposure and harsh environmental conditions.

- Safety Standards: Strict occupational health and safety regulations drive the adoption of anti-slip surfaces and secure locking mechanisms to prevent dislodgement.

- Longevity & Sustainability: A push for longer service life and reduced replacement frequency, contributing to both economic and environmental sustainability.

The market for specialized steel grating solutions, particularly those designed for unique configurations like the Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain, is projected to grow steadily as infrastructure modernization efforts continue globally. This growth is fueled by an emphasis on preventing downtime, reducing maintenance expenses, and ensuring compliance with increasingly stringent regulatory frameworks.

Detailed Manufacturing Process Flow

The production of a high-quality Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain involves a meticulously controlled manufacturing process, ensuring both precision and durability. Our process adheres to international quality standards, including ISO 9001:2015, and relevant industry specifications like ANSI/NAAMM MBG 531-00 for metal bar grating.

Materials Selection:

- Carbon Steel (Q235, A36, S235JR): Chosen for its high strength-to-cost ratio, ideal for general industrial and municipal applications.

- Stainless Steel (304, 316L): Preferred for highly corrosive environments, food processing, pharmaceuticals, and marine applications due to superior corrosion resistance.

- Galvanized Steel: Carbon steel hot-dip galvanized after fabrication for enhanced corrosion protection, extending service life significantly in exposed conditions.

Process Flow Schematic:

1. Design & Engineering

(CAD, Load Calc., Material Spec.)

2. Material Preparation

(Cutting, Shearing, Notching)

3. Shaping & Forming

(CNC Bending/Rolling for Round Shape)

4. Welding & Fabrication

(Resistance Welding, TIG/MIG for Frames)

5. Grinding & Finishing

(Smooth Edges, Deburring)

6. Surface Treatment

(Hot-dip Galvanizing, Painting, Pickling)

7. Quality Inspection

(Dimensions, Load, Finish, Weld Integrity)

8. Packaging & Delivery

(Secure for Transport)

Key Process Details:

- CNC Machining: For complex circular or special shapes, Computer Numerical Control (CNC) bending and plasma cutting ensure precise dimensions and smooth curves, which are critical for seamless integration into existing structures.

- Welding Techniques: High-resistance welding for bearing bar and cross bar joints ensures structural integrity. For frame components and heavy-duty applications, advanced TIG or MIG welding processes are utilized, achieving robust and aesthetically pleasing welds.

- Surface Treatment: Hot-dip galvanizing, performed in accordance with ASTM A123/A123M standards, provides a metallurgical bond between zinc and steel, offering superior long-term corrosion protection compared to paint or other coatings. Stainless steel gratings are often pickled and passivated to enhance their inherent corrosion resistance.

- Testing Standards: Each batch undergoes rigorous testing, including load-deflection tests (e.g., in compliance with ANSI/NAAMM MBG 531-00), material composition analysis, and visual inspections for weld integrity and surface finish.

Service Life: Depending on material and environmental conditions, carbon steel hot-dip galvanized gratings can achieve a service life of 20-50 years. Stainless steel options can exceed 50 years, often matching the lifespan of the infrastructure they serve.

Target Industries: Petrochemical, metallurgy, power generation, water supply & drainage, sewage treatment, marine, port facilities, food and beverage, manufacturing, and general municipal infrastructure.

Technical Specifications and Parameters

The performance of a Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain is defined by its precise technical specifications. These parameters dictate its load-bearing capacity, durability, and suitability for specific environments. Customization allows for the fine-tuning of these parameters to meet exact project requirements.

Key Product Specifications:

| Parameter | Typical Specification Range | Notes & Standards |

|---|---|---|

| Material Grades | Q235, A36, S235JR (Carbon Steel); 304, 316L (Stainless Steel) | ASTM, EN, GB Standards |

| Bearing Bar Sizes (Depth x Thickness) | 20x3mm to 100x8mm (Customizable) | Influences load capacity |

| Bearing Bar Pitch (Center to Center) | 20mm to 60mm (Common: 30mm, 40mm) | Affects open area and load distribution |

| Cross Bar Pitch (Center to Center) | 50mm to 100mm (Common: 50mm, 100mm) | Affects stability and rigidity |

| Circular Diameter | 300mm to 2000mm+ (Fully Customizable) | Precision CNC forming |

| Surface Treatment | Hot-dip Galvanized (ASTM A123), Mill Finish, Painted, Pickling & Passivation | Corrosion protection & aesthetics |

| Load Capacity (Uniform Load) | Class A (15kN) to Class F (900kN) - EN 124 Equivalent | Calculated based on span, bar size, and material |

| Open Area | Up to 90% (depending on bar pitch) | Ensures efficient drainage and ventilation |

| Fixing Method | Welded frame, bolted clamps, hinged options | Security and ease of access |

Understanding these specifications is crucial for engineers and project managers to select the appropriate grating for their specific operational demands, ensuring both safety and performance longevity.

Application Scenarios & Technical Advantages

The versatility and robust construction of the Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain make it indispensable across a wide array of industrial and public sector applications. Its design caters to scenarios demanding efficient drainage, heavy load support, and resistance to environmental stressors.

Typical Application Scenarios:

- Petrochemical Plants: Covering sumps and trench drains in process areas where chemical spills are a risk, requiring high corrosion resistance (e.g., 316L stainless steel options). The open structure allows for rapid dispersion of fumes and liquids, enhancing safety.

- Metallurgical Industries: Used around furnaces, cooling pits, and heavy machinery, where high temperatures, extreme loads, and abrasive wear resistance are critical.

- Water Treatment & Sewage Plants: Ideal for covering circular settling tanks, aeration basins, and pump sumps, facilitating access for maintenance while ensuring robust pedestrian and light vehicle traffic. The high open area ensures maximum flow-through.

- Power Generation Facilities: Covering drainage systems within turbine halls, cooling towers, and substation areas, where electrical safety and structural integrity under heavy loads are paramount.

- Ports & Marine Environments: Used for pier drainage, ship deck sumps, and dockside trenches, where extreme salt spray and dynamic loading require superior anti-corrosion treatments and strength.

- Food & Beverage Processing: Stainless steel versions provide hygienic drainage covers for wash-down areas, meeting strict sanitation standards.

- Urban Infrastructure: Circular tree grates, manhole covers, and public drainage systems in parks and pedestrian zones, offering aesthetic appeal alongside functionality.

Key Technical Advantages:

- Superior Load-Bearing Capacity: Precision-engineered bearing bars and cross bars, combined with robust welding, allow these gratings to withstand significant static and dynamic loads, from heavy machinery to vehicular traffic, compliant with load classes up to F (900kN) per EN 124.

- Excellent Corrosion Resistance: Options such as hot-dip galvanization (minimum 610 g/m² zinc coating as per ASTM A123) and high-grade stainless steel (304, 316L) ensure exceptional resistance to rust, chemical degradation, and environmental exposure, significantly extending the product’s service life.

- Optimal Drainage & Ventilation: The high open area, typically ranging from 60-90%, ensures efficient liquid drainage, preventing pooling and improving safety by reducing slip hazards. It also facilitates air circulation, crucial for ventilation in enclosed spaces or areas with gas build-up.

- Anti-Slip Surface Options: Serrated bearing bars or abrasive coatings can be incorporated to provide enhanced traction, particularly important in wet, oily, or icy conditions, thereby greatly improving worker safety.

- Energy Saving (Natural Ventilation): In industrial environments, effective grating design can contribute to natural ventilation strategies, reducing the reliance on mechanical ventilation systems and thus leading to energy savings.

- Ease of Maintenance: The open grid structure prevents debris accumulation and allows for easy cleaning, reducing maintenance time and costs. Optional hinge mechanisms or lifting handles further simplify access for inspections and repairs.

- Customization & Adaptability: The "customized" aspect ensures a precise fit for any unique circular sump or drain dimension, eliminating gaps and trip hazards, and optimizing integration with existing infrastructure.

These advantages collectively highlight why specialized steel grid gratings are a superior choice for demanding applications, offering a blend of safety, efficiency, and long-term economic value.

Customized Solutions for Unique Demands

The "Customized" aspect of the Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain is a critical differentiator, allowing engineers and project managers to specify precise requirements that off-the-shelf solutions cannot meet. This bespoke approach ensures optimal performance, safety, and seamless integration.

Tailoring to Your Project:

- Exact Dimensions: We fabricate gratings to precise diameters, thicknesses, and configurations, ensuring a perfect fit for existing or new circular sumps and drains, eliminating the need for on-site modifications which can compromise integrity.

- Material & Finish Selection: Choice of carbon steel, various grades of stainless steel (e.g., 304, 316, 316L), and surface treatments like hot-dip galvanization, electro-polishing, or specialized paint systems to combat specific corrosive agents or meet aesthetic requirements.

- Load Rating & Bar Spacing: Design flexibility to adjust bearing bar depth, thickness, and spacing to achieve specific load classifications (e.g., from pedestrian to heavy-duty vehicular traffic) and open area percentages for drainage efficiency.

- Security & Access Features: Integration of hinged designs, recessed lifting handles, and specialized locking mechanisms to deter unauthorized removal and ensure easy, secure access for maintenance personnel.

- Anti-Slip Enhancements: Options for serrated bearing bars or application of abrasive gritted surfaces to boost friction coefficients in high-risk areas.

- Custom Cut-outs & Penetrations: Ability to incorporate precise cut-outs for pipes, conduits, or structural supports, ensuring full functionality without compromising the grating's structural integrity.

Our engineering team collaborates closely with clients from conceptualization to installation, leveraging advanced CAD software and finite element analysis (FEA) to model performance under specific conditions. This ensures that every customized solution is not only a perfect fit but also engineered for maximum safety, efficiency, and longevity.

Vendor Comparison: Key Differentiating Factors

Selecting the right vendor for specialized steel grating is critical for project success. While many suppliers offer steel grating, not all possess the expertise, production capabilities, and commitment to quality necessary for complex, customized solutions like the Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain. A discerning evaluation focuses on several key differentiating factors:

Critical Comparison Parameters:

| Feature | Standard Vendor Offering | Specialized/Leading Vendor Offering |

|---|---|---|

| Customization Capability | Limited to standard sizes, basic shapes | Full bespoke design, complex shapes (e.g., round, irregular), precise cut-outs, CAD/FEA support |

| Engineering & Design Support | Basic drawings, no load calculations | Dedicated engineering team, load analysis, material optimization, 3D modeling, technical consultations |

| Material Quality & Traceability | Generic steel, limited certifications | Certified raw materials, mill certificates, full traceability, adherence to international material standards (ASTM, EN) |

| Manufacturing Precision | Manual processes, potential dimensional variations | Advanced CNC machinery, automated welding, tight tolerance control, high repeatability |

| Quality Control & Testing | Basic visual inspection | ISO 9001 certified, comprehensive in-house testing (load, dimensions, coating thickness), third-party verification options |

| Surface Treatment Quality | Inconsistent galvanization, limited options | Certified hot-dip galvanizing (ASTM A123), specialized coating systems, pickling & passivation for SS |

| Project Management & Lead Time | Generic production schedule, potential delays | Dedicated project managers, transparent timelines, efficient logistics, on-time delivery record |

| After-Sales Support & Warranty | Limited or no warranty, minimal support | Comprehensive warranty, responsive technical support, installation guidance, long-term partnership approach |

Choosing a vendor with proven capabilities in these areas ensures not only a compliant product but also a smoother project execution and a greater return on investment over the product's extended service life.

Application Case Studies & Customer Experience

Real-world applications highlight the tangible benefits and reliability of the Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain. Our experience with diverse industrial clients underscores our commitment to delivering tailored solutions that exceed expectations.

Case Study 1: Petrochemical Processing Plant

- Challenge: An existing petrochemical facility required robust circular sump covers (1200mm diameter) for effluent collection areas. The environment presented high corrosive risks from various chemicals and heavy mobile equipment traffic (Class E load requirements). Off-the-shelf options were either not sufficiently durable or did not fit precisely.

- Solution: We engineered and supplied Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain fabricated from 316L stainless steel, with serrated bearing bars for enhanced slip resistance. The design incorporated a custom frame that integrated seamlessly with the existing concrete sumps, ensuring a flush and secure fit. Load testing validated compliance with EN 124 Class E (400kN) for vehicular traffic.

- Outcome: The client reported a significant improvement in site safety due to the precise fit and anti-slip properties. The superior corrosion resistance of 316L SS ensures a projected service life of over 40 years, drastically reducing maintenance and replacement costs.

Case Study 2: Municipal Water Treatment Facility

- Challenge: A major municipal water treatment plant needed to replace deteriorating ductile iron covers for large aeration basins (1800mm diameter). The new covers needed to be lightweight for easy access, provide excellent ventilation, and withstand moderate pedestrian traffic.

- Solution: We designed and manufactured hot-dip galvanized carbon steel Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain with a higher open area (85%) for optimal air exchange. Each cover was designed with recessed lifting eyes and was segmented into two halves for easier handling and inspection by maintenance crews.

- Outcome: The new gratings improved operational safety by reducing manual handling strain and significantly enhanced ventilation, aiding in odor control. The hot-dip galvanized finish provided ample corrosion protection for the humid environment, projecting a 30-year maintenance-free lifespan.

These case studies exemplify our capability to deliver high-performance, precision-engineered solutions that address complex challenges and provide long-term value for our clients. Our long-standing partnerships with leading enterprises across various sectors are a testament to our authoritativeness and trustworthiness in the industry.

Ensuring Trustworthiness: FAQ, Lead Times, Warranty & Support

Frequently Asked Questions (FAQ):

Q: How do I specify a Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain for my project?

A: Provide us with the internal diameter of the sump/drain, the desired load rating (e.g., pedestrian, light traffic, heavy traffic), material preference (carbon steel, stainless steel grade), surface treatment, and any specific requirements for anti-slip features or fixing methods. Our engineering team can assist in refining these specifications.

Q: What is the typical lead time for custom grating orders?

A: Lead times vary based on complexity, material availability, and order volume. Generally, for custom round gratings, the lead time ranges from 3-6 weeks from confirmed order and drawing approval. Expedited options may be available upon request.

Q: Can you provide certification for materials and manufacturing processes?

A: Yes, we provide mill certificates for raw materials, hot-dip galvanizing certificates (compliant with ASTM A123), and our manufacturing facility operates under ISO 9001:2015 quality management system, with corresponding certification available.

Q: What is the recommended maintenance for these gratings?

A: Regular inspection for accumulated debris and potential damage is recommended. For galvanized or stainless steel, cleaning with mild detergents and rinsing with water is usually sufficient. Avoid harsh abrasives that could compromise protective coatings.

Lead Time & Fulfillment:

Our streamlined production and logistics ensure efficient order fulfillment. Standard fabrication for custom steel gratings typically falls within 3 to 6 weeks. For urgent projects, we offer expedited manufacturing and shipping options, subject to raw material availability. All products are meticulously packed to prevent transit damage, utilizing robust crating and strapping. We coordinate with reputable logistics partners to ensure timely and secure delivery globally.

Warranty Commitments:

We stand behind the quality and durability of our products. All Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain come with a comprehensive warranty against manufacturing defects and material failures under normal use and recommended maintenance. Specific warranty periods are provided with each quotation and typically range from 5 to 10 years, depending on the material and application.

Customer Support:

Our dedicated customer support team is available to assist with inquiries, technical specifications, order tracking, and post-sales support. We provide detailed installation guides and are available for consultation to ensure optimal performance and longevity of our gratings. Your satisfaction and operational continuity are our top priorities.

Conclusion

The demand for high-performance, precision-engineered drainage solutions in industrial and municipal sectors continues to grow. The Customized Special Round Shape Ditch Cover Steel Grid Grating For Sump/Drain represents the pinnacle of modern grating technology, offering unparalleled strength, corrosion resistance, and adaptability. By adhering to stringent manufacturing standards, offering comprehensive customization, and providing robust technical support, we ensure that our solutions not only meet but exceed the complex requirements of critical infrastructure projects. Investing in specialized grating solutions guarantees long-term operational efficiency, enhanced safety, and a superior return on investment.

References

- American Society for Testing and Materials (ASTM). ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- National Association of Architectural Metal Manufacturers (NAAMM). MBG 531-00: Metal Bar Grating Manual.

- International Organization for Standardization (ISO). ISO 9001:2015: Quality Management Systems – Requirements.

- European Standard (EN). EN 124: Gully tops and manhole covers for vehicular and pedestrian areas – Design requirements, type testing, marking, quality control.

- Corrosionpedia. "Hot-Dip Galvanizing." Corrosionpedia.com.

- Steel Construction Institute (SCI). "Guidance on the Design of Steel Grid Floors."

Latest News

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

-

Grating Plumbing: Durable & Efficient Drainage Solutions For Modern Infrastructure

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA