Sep . 23, 2025 15:05 Back to list

Bulk Woven Wire Fence: Cost-Effective 2x4 & 6ft Mesh

Industry Trends and Market Demand for Woven Wire Fencing

The global market for industrial fencing solutions, particularly those utilizing robust materials like woven wire mesh, is experiencing significant growth driven by expanding infrastructure, increased security requirements across various sectors, and the demand for durable, low-maintenance materials. Among these, the procurement of bulk woven wire fence has become a strategic imperative for B2B entities in sectors ranging from agriculture to heavy industry.

Current trends indicate a strong preference for galvanized and stainless steel woven wire mesh due to their superior corrosion resistance and longevity, especially in harsh environmental conditions. There's an increasing emphasis on customizable specifications, such as specific mesh sizes like 2 x 4 woven wire fencing and varying heights, including 6 foot woven wire fence, to meet diverse application requirements. The market is also seeing innovation in weaving techniques and coating technologies, enhancing product performance and extending service life, thereby reducing total cost of ownership (TCO) for large-scale projects.

Demand is particularly robust from the energy sector, chemical processing, maritime operations, and large-scale agricultural enterprises, all requiring reliable, long-term containment and security solutions. The shift towards sustainable and recyclable materials also positions woven wire fence products favorably, as steel is a highly recyclable commodity.

Manufacturing Process of Woven Wire Fence

The production of high-quality bulk woven wire fence involves a meticulous multi-stage process designed to ensure product integrity, durability, and compliance with international standards. Our manufacturing adheres to stringent quality control measures, often exceeding ISO 9001 and ANSI specifications.

Detailed Process Flow:

- Material Selection & Preparation: We primarily utilize high-grade carbon steel wire (e.g., Q195, Q235) for galvanized products or various grades of stainless steel (e.g., SS304, SS316, SS316L) for enhanced corrosion resistance. Wires are selected based on required tensile strength, ductility, and application environment.

- Wire Drawing: Raw steel rods are drawn through a series of dies to achieve the precise wire diameter required for the specified mesh configuration. This process increases tensile strength and refines the wire's surface.

- Galvanization (for Galvanized Products): For galvanized square woven wire mesh, the drawn wires undergo hot-dip galvanization or electro-galvanization. Hot-dip galvanization involves immersing the wire in molten zinc (typically 99.995% pure zinc) at approximately 450°C. This creates a metallurgical bond, forming a durable, corrosion-resistant zinc coating. Coating thickness is rigorously controlled, often exceeding ASTM A123 standards.

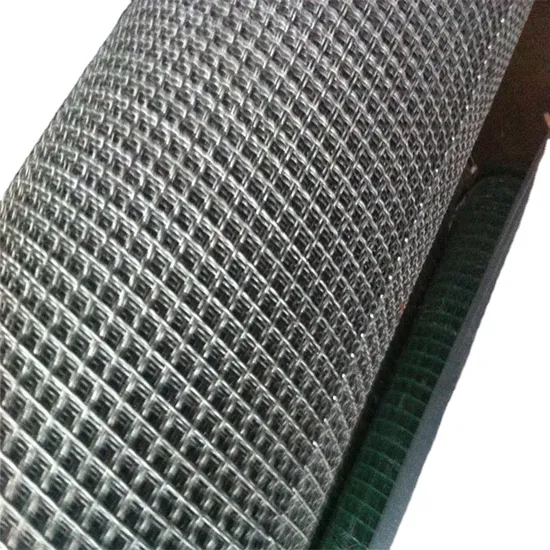

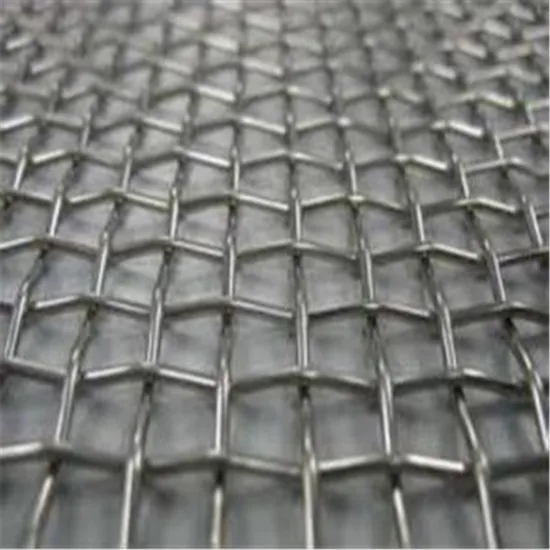

- Weaving: The galvanized or stainless steel wires are fed into specialized weaving looms. These machines precisely interlace horizontal (weft) and vertical (warp) wires to create the desired mesh pattern and aperture size, such as square or rectangular weaves, including the common 2 x 4 woven wire fencing. The weaving process ensures uniform mesh spacing and robust intersections, preventing unraveling.

- Crimping (Optional): For specific applications requiring increased stability or filter media, wires may be crimped prior to weaving. This process creates pre-bent wires, allowing for larger mesh openings and enhancing structural rigidity.

- Flattening & Cutting: Post-weaving, the continuous mesh sheet may pass through flattening rollers to ensure optimal flatness. It is then cut into predetermined panel sizes or rolled into bulk quantities like a 6 foot woven wire fence roll, based on client specifications.

- Edge Finishing: Edges are typically selvage-edged (knuckled or twisted) to provide a smooth finish, prevent sharp protrusions, and enhance the structural integrity of the fence panels or rolls.

- Quality Control & Testing: Each batch undergoes comprehensive quality assurance, including mesh count verification, wire diameter measurement, zinc coating thickness testing (for galvanized products), tensile strength tests, and visual inspection for defects. Compliance with international standards such as ISO 9001 and ANSI is strictly maintained.

- Packaging: Finished products are carefully packaged, typically in rolls wrapped with moisture-resistant paper and plastic film, or on pallets for panels, to prevent damage during transit and storage.

The typical service life for galvanized woven wire mesh can exceed 20 years, while stainless steel fine mesh screen can last significantly longer, often 50+ years, depending on environmental conditions and maintenance. Target industries benefitting from our expertise include petrochemical, metallurgy, mining, water supply & drainage, agriculture, and construction. Key advantages in these scenarios include superior corrosion resistance, high tensile strength for enhanced security, and minimal maintenance leading to energy saving in operational costs.

Technical Specifications: Wholesale Galvanized Square Woven Wire Mesh

Our bulk woven wire fence products are manufactured to precise technical specifications, ensuring consistent performance and reliability across diverse applications. Below are typical parameters for our Wholesale Galvanized Square Woven Wire Mesh.

Product Specification Table

| Parameter | Specification Details | Standard (Typical) |

|---|---|---|

| Material | Low Carbon Steel Wire (Q195, Q235) | ASTM A792 |

| Surface Treatment | Hot-Dip Galvanized, Electro Galvanized | ASTM A123 (Hot-Dip) |

| Mesh Size (Aperture) | From 1/4 inch to 4 inches (e.g., 2 x 4 woven wire fencing) | Custom per request |

| Wire Diameter (Gauge) | From 0.6mm (22 Gauge) to 4mm (8 Gauge) | BWG (Birmingham Wire Gauge) |

| Zinc Coating Thickness | Hot-Dip: 40-300 g/m²; Electro: 10-20 g/m² | ISO 1461, ASTM A90 |

| Tensile Strength | 350-550 N/mm² (for wire before weaving) | ASTM A853 |

| Roll Width | 0.5m to 2.5m (e.g., 6 foot woven wire fence) | Custom per request |

| Roll Length | 15m to 50m (50ft to 164ft) | Custom per request |

| Weave Type | Plain Weave (standard square mesh) | Industry Standard |

These specifications are crucial for engineers and procurement managers to ensure that the chosen woven wire mesh meets the structural, environmental, and functional demands of their projects. Our commitment to adhering to these precise parameters underpins the reliability and longevity of our products.

Application Scenarios and Technical Advantages

The versatility and robust characteristics of bulk woven wire fence make it indispensable across a multitude of industrial and commercial applications. Its inherent strength, combined with specific material treatments, provides significant technical advantages.

Key Application Scenarios:

- Security Fencing: Widely deployed in industrial perimeters, correctional facilities, power plants, and military bases due to its anti-climb properties and resistance to cutting. A robust 6 foot woven wire fence offers substantial deterrence.

- Animal Enclosures & Agriculture: Essential for livestock containment (cattle, sheep, poultry) and wildlife exclusion, especially for options like 2 x 4 woven wire fencing which prevents smaller animals from passing through.

- Industrial Filtration & Sieving: Finer woven wire mesh, including stainless steel fine mesh screen, is critical in chemical, pharmaceutical, and food processing industries for separation, screening, and particulate filtration.

- Construction & Infrastructure: Used as reinforcement mesh, plaster mesh, or temporary barriers on construction sites, offering structural support and safety.

- Architectural & Decorative Applications: Increasingly used in modern architecture for facades, balustrades, sunscreens, and interior design elements due to its aesthetic appeal and durability.

Technical Advantages:

- Superior Corrosion Resistance: Hot-dip galvanization provides a formidable barrier against rust and environmental degradation, significantly extending product lifespan in outdoor and humid conditions. Stainless steel variants offer even greater resistance to chemical corrosion.

- High Tensile Strength: The use of high-grade steel wire and precision weaving results in a mesh structure with excellent tensile strength, capable of withstanding significant impact and stress, crucial for security applications.

- Dimensional Stability: The woven construction ensures that the mesh retains its shape and aperture size under tension and varying temperatures, preventing deformation over time.

- Low Maintenance & Longevity: Due to corrosion resistance and robust construction, these fences require minimal maintenance, leading to substantial long-term cost savings (energy saving in terms of resources for repair/replacement).

- Versatility in Mesh Design: Capabilities to produce various mesh patterns, wire diameters, and opening sizes, allowing for tailored solutions from fine filtration to heavy-duty security.

Vendor Comparison and Customized Solutions

When procuring bulk woven wire fence, discerning B2B clients evaluate vendors not just on price, but on product quality, customization capabilities, certification, and post-sales support. Below is a comparison to highlight key differentiators:

Woven Wire Mesh Vendor Comparison

| Feature | Standard Vendor (Typical) | Our Company (Premium/Custom) |

|---|---|---|

| Material Quality | Basic commercial grade steel, sometimes inconsistent galvanization. | High-grade low carbon steel (Q195/Q235) or certified SS304/SS316, with uniform, thick galvanization (ASTM A123). |

| Mesh Precision | Variable mesh opening sizes, potential for weaving inconsistencies. | CNC-controlled weaving for exact mesh apertures (e.g., precise 2 x 4 woven wire fencing). |

| Customization | Limited options for wire gauge, mesh size, or roll dimensions. | Extensive customization: material, wire gauge, mesh size, panel/roll dimensions (e.g., custom 6 foot woven wire fence), edge finishing. |

| Certifications | May lack international certifications or provide basic compliance. | ISO 9001 certified manufacturing, adherence to ASTM, ANSI, and local standards. Test reports available. |

| Engineering Support | Minimal technical assistance or design consultation. | Dedicated engineering team for project consultation, material selection, and custom design optimization. |

| Lead Time & Fulfillment | Standard lead times, less flexibility for urgent orders. | Optimized production schedule for competitive lead times, flexible for large-scale and urgent projects. |

Customized Solutions

Our expertise extends to providing highly tailored woven wire mesh solutions. Recognizing that standard products may not suffice for specialized industrial applications, we offer comprehensive customization options:

- Material Choice: Beyond galvanized steel, we offer various stainless steel grades (SS304, SS316, SS316L) for chemical resistance, high-temperature alloys, and specialized coatings.

- Mesh Configuration: Precision manufacturing for specific mesh apertures, wire diameters, and weave patterns (e.g., plain, twilled, dutch weave) to meet exact filtration or structural requirements. This includes unique specifications for woven wire mesh.

- Dimensions: Production of panels or rolls in bespoke widths and lengths, accommodating large-scale projects or unique installation environments.

- Edge Treatment: Options for specific selvage types (knuckled, twisted, welded) to suit handling, aesthetic, or security needs.

Our engineering team collaborates closely with clients from conceptualization to deployment, ensuring that every customized solution delivers optimal performance and cost-efficiency.

Application Case Studies

Our bulk woven wire fence solutions have been successfully implemented in critical infrastructure projects globally. These case studies illustrate our capacity to deliver high-performance, reliable woven wire mesh products tailored to demanding industrial requirements.

Case Study 1: Petrochemical Plant Perimeter Security

- Client:

- Major International Petrochemical Corporation, Middle East

- Challenge:

- The client required a highly robust and corrosion-resistant perimeter security fence for a new refinery expansion situated in a coastal, high-salinity environment. The fence needed to withstand extreme weather, resist tampering, and integrate with advanced security systems. The project demanded approximately 50 kilometers of continuous fencing.

- Solution:

- We supplied customized hot-dip galvanized 6 foot woven wire fence with a specific wire gauge and tight 2 x 4 woven wire fencing mesh pattern. The galvanization thickness was specified to exceed ASTM A123 heavy class standards to ensure exceptional longevity in the corrosive coastal atmosphere. Our engineering team provided consultation on optimal tensioning and post-installation integration for motion sensors and surveillance cameras.

- Results:

- The project was completed on schedule, providing a secure, impenetrable perimeter. Independent inspections confirmed the superior quality of the galvanized coating. The client reported significant operational savings due to the fence's minimal maintenance requirements and extended projected service life.

Case Study 2: Large-Scale Agricultural Containment

- Client:

- Regional Agricultural Cooperative, Midwest USA

- Challenge:

- The cooperative needed to secure vast grazing areas for cattle and sheep while also deterring local wildlife (deer, coyotes). They required a cost-effective, durable fencing solution that could be installed efficiently over undulating terrain and withstand varied seasonal weather conditions.

- Solution:

- We supplied bulk woven wire fence rolls, specifically a graduated mesh design (tighter at the bottom, wider at the top) to effectively contain smaller livestock and deter larger wildlife. The wire was heavily galvanized to resist rust from rain and animal waste. We provided guidance on appropriate post spacing and tensioning techniques for maximum effectiveness across varied topography.

- Results:

- The cooperative successfully installed over 100 kilometers of fencing. The durable woven wire mesh minimized livestock escapement and significantly reduced crop damage from wildlife. The robust construction ensures decades of reliable performance, validating the initial investment.

Frequently Asked Questions (FAQ)

- Q1: What is the typical lead time for bulk woven wire fence orders?

- A1: Standard bulk orders generally have a lead time of 2-4 weeks, depending on quantity and current production schedules. Custom orders may require an additional 1-2 weeks for engineering and specialized fabrication. We strive to provide accurate lead times at the time of quotation.

- Q2: What is your warranty policy for woven wire mesh products?

- A2: We offer a comprehensive warranty against manufacturing defects in materials and workmanship for a period of 5 years from the date of purchase. Our galvanized products typically come with a performance guarantee for zinc coating integrity for 10-20 years, depending on environmental factors and adherence to installation guidelines. Specific warranty details are provided with each quotation.

- Q3: Can you produce woven wire mesh in custom sizes, such as specific 6 foot woven wire fence heights or unique 2 x 4 woven wire fencing patterns?

- A3: Yes, customization is a core service. We can manufacture woven wire mesh to precise specifications, including custom roll widths, lengths, wire diameters, mesh apertures, and material grades (e.g., various stainless steel fine mesh screen options). Our engineering team will work with you to ensure your exact requirements are met.

- Q4: What kind of after-sales support do you provide?

- A4: We provide robust after-sales support including technical guidance for installation, maintenance recommendations, and prompt assistance for any product-related inquiries or issues. Our dedicated customer service team is available via phone, email, and online portal to ensure long-term client satisfaction.

- Q5: How does your product meet international quality standards?

- A5: Our manufacturing facilities are ISO 9001 certified. All products undergo rigorous quality control, adhering to international standards such as ASTM (American Society for Testing and Materials), ANSI (American National Standards Institute), and relevant European EN standards. We provide material test certificates and quality assurance documentation with every shipment.

Lead Time, Warranty, and Customer Support

Our commitment to B2B partners extends beyond product delivery, encompassing efficient logistics, robust warranties, and comprehensive customer support to ensure maximum operational uptime and client satisfaction.

Lead Time and Fulfillment

For standard bulk woven wire fence orders, our typical lead time is between 15-30 business days from order confirmation, depending on the volume and specific product type (e.g., galvanized square woven wire mesh vs. stainless steel fine mesh screen). We maintain optimized inventory levels for common specifications to expedite fulfillment. For highly customized or large-scale project orders, lead times are collaboratively established during the quoting phase, providing transparency and allowing for precise project planning. We leverage a robust logistics network to ensure timely and secure delivery worldwide, accommodating various shipping terms (FOB, CIF, DDP).

Warranty Commitments

We stand by the quality and durability of our woven wire products. All our products are backed by a comprehensive warranty against manufacturing defects, typically for a period of five (5) years. For hot-dip galvanized products, we guarantee the zinc coating’s integrity against premature corrosion for an extended period, often 10-20 years, dependent on environmental conditions and proper installation as per industry standards (e.g., ISO 1461, ASTM A123). Detailed warranty statements are provided with each purchase agreement, outlining terms, conditions, and claims procedures.

Customer Support and After-Sales Service

Our dedication to our clients continues long after the sale. We offer multi-channel customer support designed to assist with any technical inquiries, installation guidance, or post-purchase issues:

- Technical Support: Access to our team of product engineers for consultation on product application, material compatibility, and optimization of woven wire mesh solutions for specific project demands.

- Dedicated Account Managers: Each client is assigned a dedicated account manager to streamline communication and ensure personalized service throughout the order lifecycle.

- Documentation and Resources: Provision of comprehensive product data sheets, installation guides, and maintenance recommendations to ensure the optimal performance and longevity of the fence.

- Rapid Response: Commitment to timely responses for inquiries and issue resolution, minimizing any potential disruption to your operations.

Our goal is to forge lasting partnerships by consistently delivering high-quality products and unparalleled service.

References

- ASTM International. ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- ISO 9001:2015 - Quality management systems - Requirements. International Organization for Standardization.

- National Association of Corrosion Engineers (NACE International). Corrosion Basics – An Introduction.

- American Society of Civil Engineers (ASCE). Structural Engineering Institute (SEI) publications on fencing and barriers.

- Wire Association International (WAI). Wire & Cable Technical Handbook.

Latest News

-

Durable and Custom Metal Grid for Drainage Solutions | Chengsen Mesh

NewsNov.24,2025

-

Durable Metal Drain Grill Solutions | Urban & Industrial Drainage Experts

NewsNov.23,2025

-

Hinged Grating: Durable, Safe, and Efficient Infrastructure Access Solutions

NewsNov.22,2025

-

What Is a Grating Wall? Benefits, Uses & Industry Trends Explained

NewsNov.21,2025

-

Durable and Customizable Grating Stainless for Industrial & Infrastructure Needs

NewsNov.20,2025

-

Grating Plumbing: Durable & Efficient Drainage Solutions For Modern Infrastructure

NewsNov.20,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA