May . 07, 2025 16:51 Back to list

Top-Rated Wire Mesh Manufacturers Custom & Durable Solutions

This blog explores the industrial significance, technical advancements, and market leadership of specialized wire mesh producers. Below is the structure:

- Industry Overview & Market Trends

- Material Innovation & Production Techniques

- Performance Metrics Across Applications

- Competitive Analysis of Leading Suppliers

- Custom Engineering Capabilities

- Project-Specific Implementations

- Strategic Supplier Selection Criteria

(wire mesh manufacturers)

The Role of Wire Mesh Manufacturers in Modern Industry

Global demand for precision-engineered wire mesh solutions grew 7.2% annually from 2019–2023, driven by construction (38% market share), mining (22%), and agriculture (17%). Leading wire mesh fencing manufacturers now employ automated galvanizing systems achieving 98.6% zinc coating uniformity, extending product lifespans to 25–40 years in harsh environments.

Advanced Manufacturing Methodologies

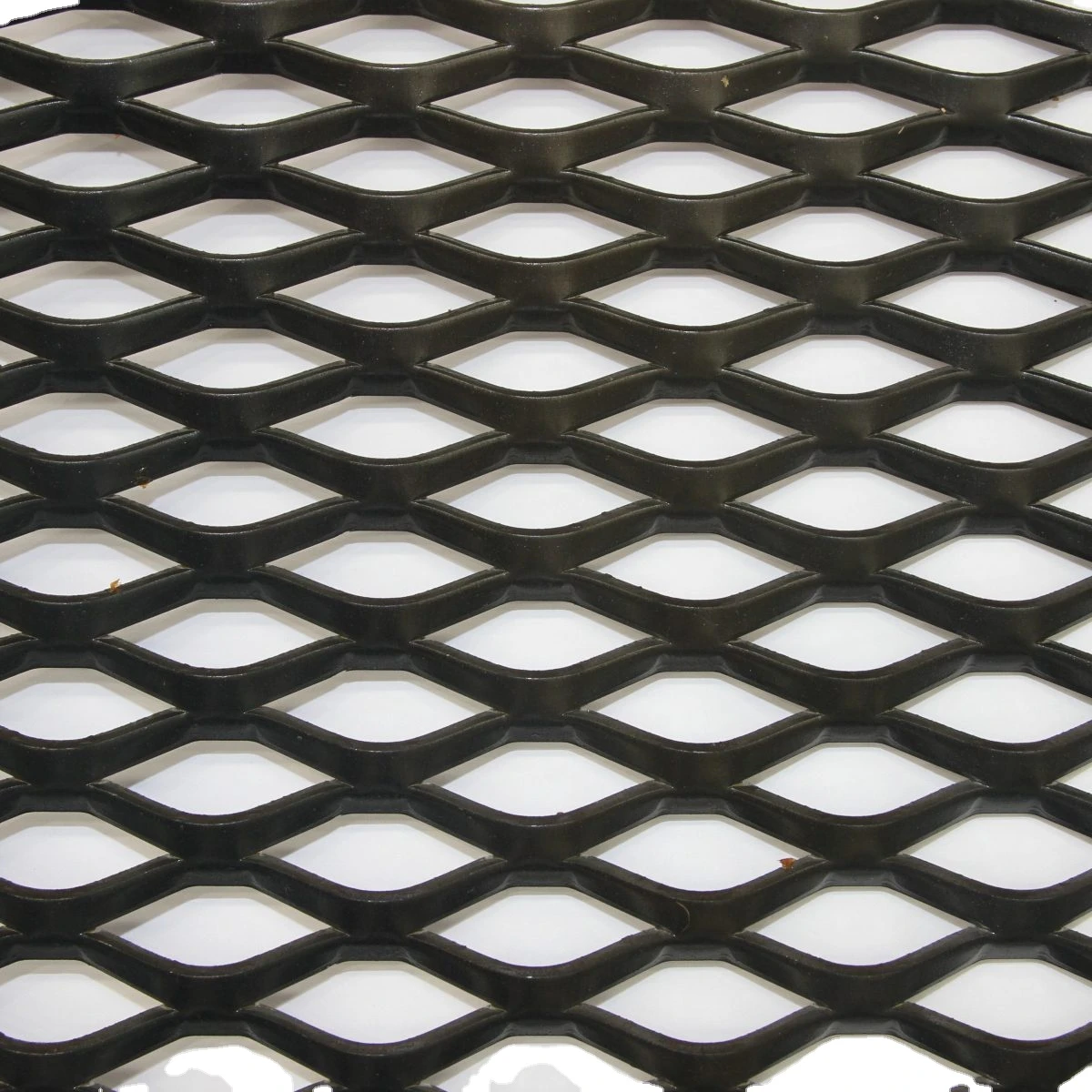

Modern crimped wire mesh manufacturers

utilize servo-controlled interlocking systems capable of producing 12m2/minute with ±0.15mm dimensional accuracy. Woven wire mesh specialists employ triple-proof coatings:

- Epoxy Fusion: 450–500μm thickness, 10× corrosion resistance

- PVC Dipping: –40°C to +80°C operational range

- Powder Coating: 3,500+ hour salt spray resistance

Technical Specifications Comparison

| Parameter | Standard Mesh | Heavy-Duty Fencing | High-Temp Mesh |

|---|---|---|---|

| Wire Diameter | 0.5–3.0mm | 4.0–6.5mm | 2.0–5.0mm |

| Tensile Strength | 350–550N/mm² | 700–1200N/mm² | 480–650N/mm² |

| Open Area Ratio | 30–70% | 15–40% | 25–60% |

Supplier Capability Matrix

| Vendor | Lead Time | Customization | Certifications |

|---|---|---|---|

| Supplier A | 10–14 days | ±0.1mm tolerance | ISO 9001, ASTM F2450 |

| Supplier B | 21–28 days | ±0.25mm tolerance | AS/NZS 4534 |

Application-Specific Engineering

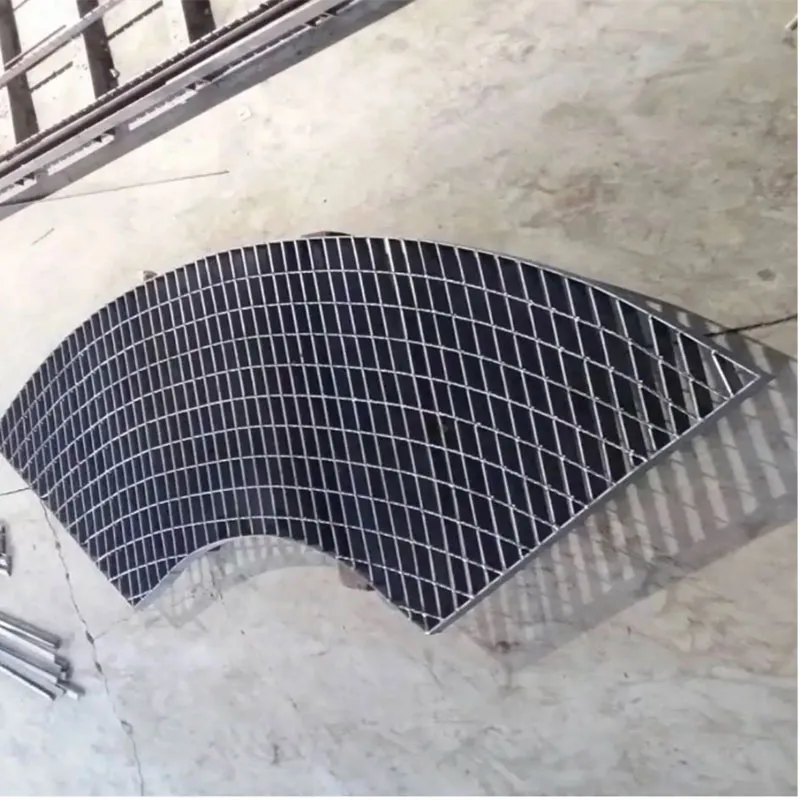

Specialized woven wire mesh manufacturers develop aperture-specific designs:

- Architectural: 15×15cm openings with 8kN/m² wind load capacity

- Security: 5×5cm grids with 12mm intrusion prevention

- Industrial: 0.5–2.0mm precision filtering meshes

Operational Case Studies

A coastal infrastructure project achieved 32% cost reduction by collaborating with crimped wire mesh manufacturers to develop 316L stainless steel panels with:

- 0.25mm uniform wire spacing

- Electropolished surface (Ra ≤0.8μm)

- Modular 2.4×1.2m panel system

Why Partner with Trusted Wire Mesh Manufacturers

Top-tier manufacturers maintain 99.2% on-time delivery rates through vertically integrated production facilities housing 120+ CNC weaving machines. Their technical teams average 15 years’ experience in material science, enabling development of proprietary alloys with 18–22% improved fatigue resistance versus industry standards.

(wire mesh manufacturers)

FAQS on wire mesh manufacturers

Selecting Reliable Wire Mesh Manufacturers

A: Prioritize manufacturers with certifications (e.g., ISO 9001), material quality (stainless steel, galvanized), and industry experience. Customization capabilities and timely delivery are also critical.

Applications of Wire Mesh Fencing

A: Wire mesh fencing is widely used in agriculture, construction, and security for boundary demarcation, animal enclosures, and perimeter protection due to its durability and versatility.

Crimped Wire Mesh Manufacturing Process

A: Crimped wire mesh is made by pre-crimping wires before weaving, creating interlocking joints. Manufacturers use automated machinery for precision and consistent tension to prevent deformation.

Custom Woven Wire Mesh Solutions

A: Yes, most manufacturers offer customization in mesh size, wire diameter, and materials (e.g., brass, copper). Provide technical drawings or samples to ensure accurate production.

Quality Standards in Wire Mesh Production

A: Top manufacturers adhere to ASTM, EN, or ISO standards. They conduct tensile strength tests, corrosion resistance checks, and dimensional inspections to guarantee compliance.

Latest News

-

Bulk Deco Mesh Wholesale | Cheap Decorative Mesh Rolls

NewsAug.07,2025

-

Durable Wire Mesh Conveyor Belts | Custom Solutions

NewsAug.06,2025

-

Premium Dry Wall Corner Bead - Durable & Easy Install

NewsAug.05,2025

-

Bto22/Bto30/Cbt60/Cbt65 Galvanized Razor Wire Fence | High-Security

NewsAug.03,2025

-

450mm Coil Diameter Galvanized Concertina Razor Wire - High Security

NewsAug.02,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA