7 月 . 15, 2025 11:45 返回列表

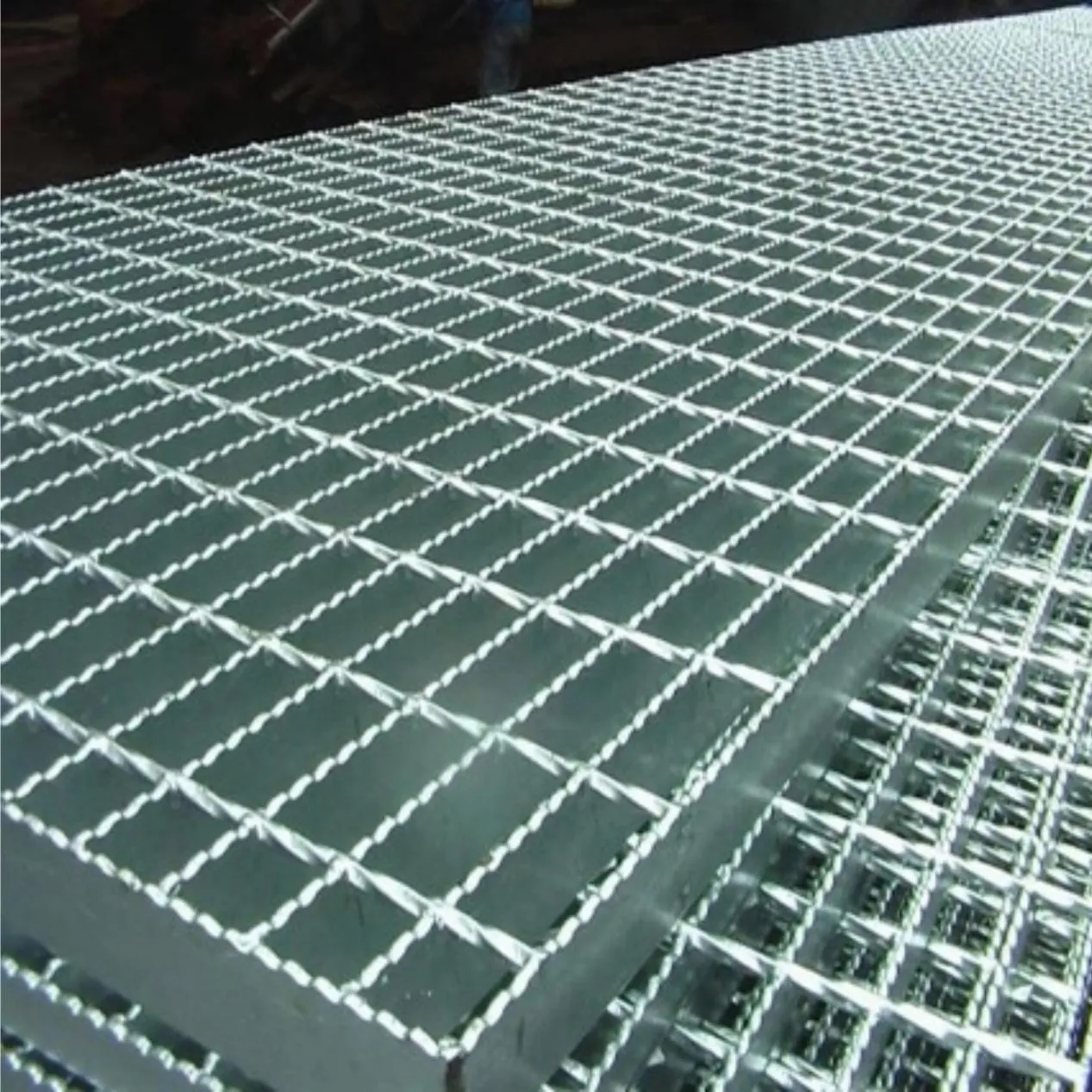

Thermal Expansion Management Strategies for Serrated Steel Grating Systems

Effective thermal expansion management is critical for ensuring the longevity, safety, and functionality of steel grating systems. Serrated steel grating, 沟渠排水篦子, driveway drain grates, 和 steel drainage grates are widely used in industrial, commercial, and residential applications due to their durability and slip-resistant properties. However, temperature fluctuations can cause expansion and contraction, leading to structural stress, misalignment, or even failure if not properly addressed. This article explores proven strategies to manage thermal expansion in these systems, ensuring optimal performance across diverse environments.

Understanding Thermal Expansion in Serrated Steel Grating Systems

Serrated steel grating is a popular choice for walkways, platforms, and stair treads due to its enhanced grip and load-bearing capacity. However, steel’s inherent property of expanding under heat poses challenges. For every 100°F temperature increase, steel expands approximately 0.6 inches per 100 feet. In outdoor installations, such as bridges or industrial sites, daily and seasonal temperature swings can accumulate significant stress.

To mitigate this, engineers incorporate expansion joints during installation. These joints allow controlled movement, preventing warping or buckling. Additionally, selecting alloys with lower thermal expansion coefficients, such as stainless steel variants, can reduce overall displacement. Anchoring systems must also be designed to accommodate movement—fixed anchors at one end and sliding anchors at the other ensure even stress distribution.

Regular inspections are vital. For 锯齿钢格栅 exposed to extreme temperatures, monitoring for signs of deformation or loosened fasteners helps preempt failures. Manufacturers often pre-cut gratings with tolerance gaps based on regional climate data, ensuring long-term stability.

Thermal Considerations for Trench Drain Grate Installations

Trench drain grates are essential for managing water runoff in parking lots, airports, and manufacturing facilities. Their linear design makes them susceptible to thermal expansion along their length. Unlike modular systems, continuous trench drains require precise planning to avoid misalignment.

One effective strategy involves segmenting long trench runs into shorter sections with expansion joints. These joints, filled with flexible sealants, absorb movement without compromising drainage efficiency. For 沟渠排水篦子 systems embedded in concrete, isolating the grate from the surrounding material using elastomeric pads prevents stress transfer during temperature changes.

Material selection also plays a role. Cast iron or ductile iron grates may be paired with steel frames to balance thermal behavior. Additionally, slotted bolt holes in mounting hardware allow slight lateral shifts, accommodating expansion while maintaining secure fastening.

Driveway Drain Grates: Balancing Load Capacity and Thermal Movement

Driveway drain grates face unique challenges due to vehicular traffic and exposure to weather. Thermal expansion can cause grates to shift, creating tripping hazards or gaps that compromise drainage. Heavy-duty driveway drain grates often use reinforced frames with welded joints to resist deformation.

A key strategy is integrating modular designs. By dividing large grates into smaller, interlocking panels, thermal movement is localized, reducing cumulative stress. For example, a 10-foot driveway grate might be split into three panels with hidden expansion gaps. The use of high-tensile steel further enhances resistance to warping.

Installation techniques matter. Embedding grates in a bed of compacted gravel rather than rigid concrete allows slight movement while maintaining load distribution. Additionally, periodic adjustments during seasonal transitions—tightening bolts or resealing joints—ensure sustained performance.

Optimizing Steel Drainage Grates for Variable Temperature Conditions

Steel drainage grates are ubiquitous in municipal and industrial settings. Their open-grid design facilitates efficient water flow but requires careful thermal management. In regions with wide temperature ranges, such as deserts or alpine areas, daily cycles of heating and cooling can fatigue materials over time.

To address this, manufacturers optimize grate geometry. Curved or corrugated surfaces distribute thermal stress more evenly than flat designs. Coatings like hot-dip galvanizing or epoxy not only prevent corrosion but also reduce friction between connected components, allowing smoother expansion.

For large-scale installations, such as airport runways, computational modeling predicts thermal behavior. This data informs the spacing of support beams and fastener types. For example, spring-loaded clips might replace rigid welds to permit movement.

FAQs About Thermal Expansion in Serrated Steel Grating Systems

How does thermal expansion affect serrated steel grating over time?

Prolonged thermal cycling can cause 锯齿钢格栅 to warp or develop stress fractures. Proper joint design, material selection, and routine maintenance minimize these risks, ensuring decades of reliable service.

Can trench drain grates crack due to temperature changes?

Yes, if installed without expansion joints, trench drain grates may crack or shift. Segmenting drains and using flexible sealants are standard practices to prevent such issues.

Are driveway drain grates prone to lifting in hot weather?

In extreme heat, poorly anchored driveway drain grates may lift. Slotted mounting holes and modular designs allow controlled movement while keeping grates securely in place.

What coatings are best for steel drainage grates in variable climates?

Hot-dip galvanizing and epoxy coatings are ideal for steel drainage grates, offering corrosion resistance and reduced thermal stress through smoother surface interaction.

How often should serrated steel grating be inspected?

Annual inspections are recommended for systems exposed to severe temperature swings. Check for sealant degradation, fastener integrity, and alignment in 锯齿钢格栅, 沟渠排水篦子, and other systems.

Managing thermal expansion in 锯齿钢格栅, 沟渠排水篦子, driveway drain grates, 和 steel drainage grates requires a combination of strategic design, material science, and proactive maintenance. By understanding the unique demands of each application and implementing tailored solutions, manufacturers and installers can ensure these systems withstand temperature fluctuations while delivering unmatched durability and safety. As industries continue to prioritize resilient infrastructure, these strategies will remain foundational to successful steel grating deployments worldwide.

最新消息

-

Ventilation Optimization with Perforated Galvanized Grating in Factories

消息Jul.15,2025

-

Eco-friendly Advantages of Aluminium Corner Beads

消息Jul.15,2025

-

Drywall Corner Types for Ceilings

消息Jul.15,2025

-

Customizable Aluminum Grating Designs for Aesthetic Facades

消息Jul.15,2025

-

Budget-Friendly Renovation Using PVC Corner Bead

消息Jul.15,2025

我公司拥有优秀的CAD钢格板图纸设计师,能为客户提供完美的钢格板排版设计,更好的满足客户对产品的特殊要求。我们一直秉承“质量第一,客户至上”的经营宗旨,以优质的产品,合理的价格,最快的交货期,竭诚为客户提供全方位的服务!欢迎新老客户真诚合作,共创辉煌!

联系我们

欢迎来到我们公司!

感谢您对我们服务的关注!如果您有任何疑问或想预订服务,请随时联系我们。我们的团队致力于为您提供最高水平的服务和支持,我们致力于与您合作,让您的活动取得成功。

服务电子邮件

服务电话

联系我们

- 电话: +86 +86 15733154345

- 电子邮件: sales@chengsenchina.com

- 地址: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA