Th2 . 13, 2025 13:11 Back to list

white plastic angle bead

The authoritativeness of white plastic angle beads in construction extends beyond mere functionality. These components play a pivotal role in safety, contributing to the structural integrity of buildings by reinforcing edges susceptible to impact damage. Case studies have shown that structures reinforced with plastic angle beads experience fewer incidences of cracks and chips, testifying to their robustness in high-traffic areas. Structural engineers and builders with authoritative voices within the industry advocate for the use of these beads as a standard practice, underpinning their utility in both residential and commercial buildings. Trustworthiness in building components is paramount. White plastic angle beads have gained the trust of industry professionals due to their consistent performance and compliance with safety standards. Manufacturers ensure that these products undergo rigorous quality checks, further cementing their reputation in the market. Builders place their trust in these well-vetted products, knowing that their proven track record translates into durability and client satisfaction. In conclusion, white plastic angle beads stand out as a versatile and essential component within the construction industry. By bolstering the durability and visual appeal of plastered surfaces, they provide both practical and aesthetic advantages. The wealth of experience from professionals, combined with expert guidelines and proven effectiveness, positions these beads as a trusted, authoritative choice for all building projects. By leveraging the strengths of the white plastic angle bead, construction professionals can assure the longevity, beauty, and quality of their work, fulfilling both technical requirements and client aspirations in equal measure.

Latest News

-

450mm Coil Diameter Galvanized Concertina Razor Wire - High Security

NewsAug.02,2025

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

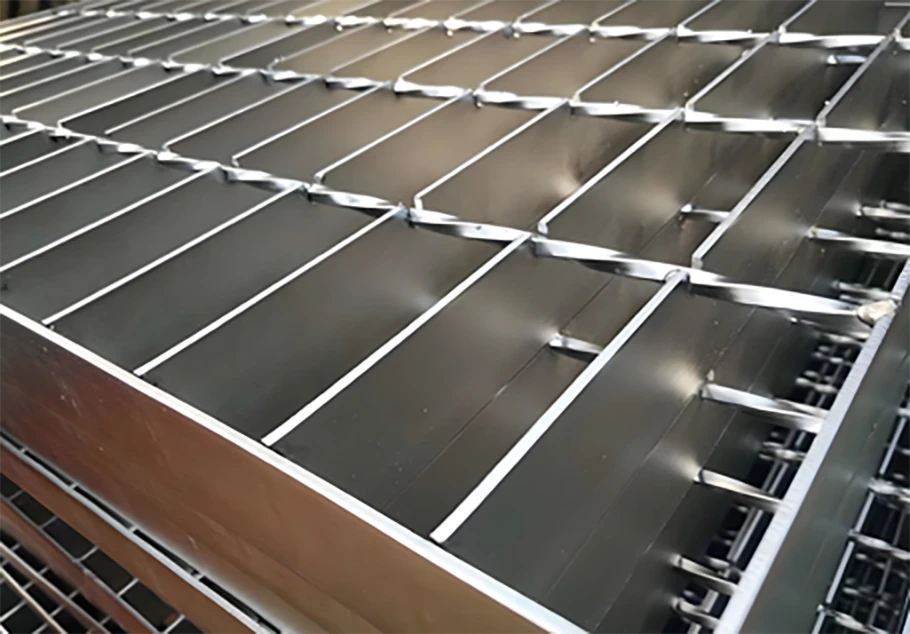

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA