Th2 . 14, 2025 12:33 Back to list

paper corners for drywall

Once dried, subsequent layers of joint compound are applied and feathered out to blend the paper corner seamlessly into the surrounding wall. Typically, three coats will create a durable, imperfection-free corner. It's critical to sand between coats lightly, using fine-grit sandpaper to achieve a smooth transition from corner to wall surface. Remember to clean the surface of any dust before applying additional coats, as debris can cause visible imperfections. Apart from their functional benefits, paper corners contribute significantly to the aesthetic appeal of a space. Well-executed corners yield a sense of precision and harmony, enhancing the overall look and feel of a room. They serve as a testament to meticulous craftsmanship, often commanding respect from peers and clients alike. Equipped with the knowledge of how to utilize paper corners effectively, both novices and seasoned professionals can rest assured of superior results. As with many components in construction and renovation, mastery comes from experience and attention to detail. However, the foundational understanding of product benefits and installation techniques instills confidence and competence. In summary, the strategic use of paper corners for drywall is a simple yet transformative approach to drywall finishing. They offer superior performance, ease of use, and an enhanced finished appearance compared to traditional metal alternatives. Establishing expertise in this area not only boosts the durability of drywall installations but also augments a project’s overall aesthetic value. Confidence in applying these principles fosters a reputation of authority and trustworthiness in the field, ultimately ensuring the success and satisfaction of every drywall project undertaken.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

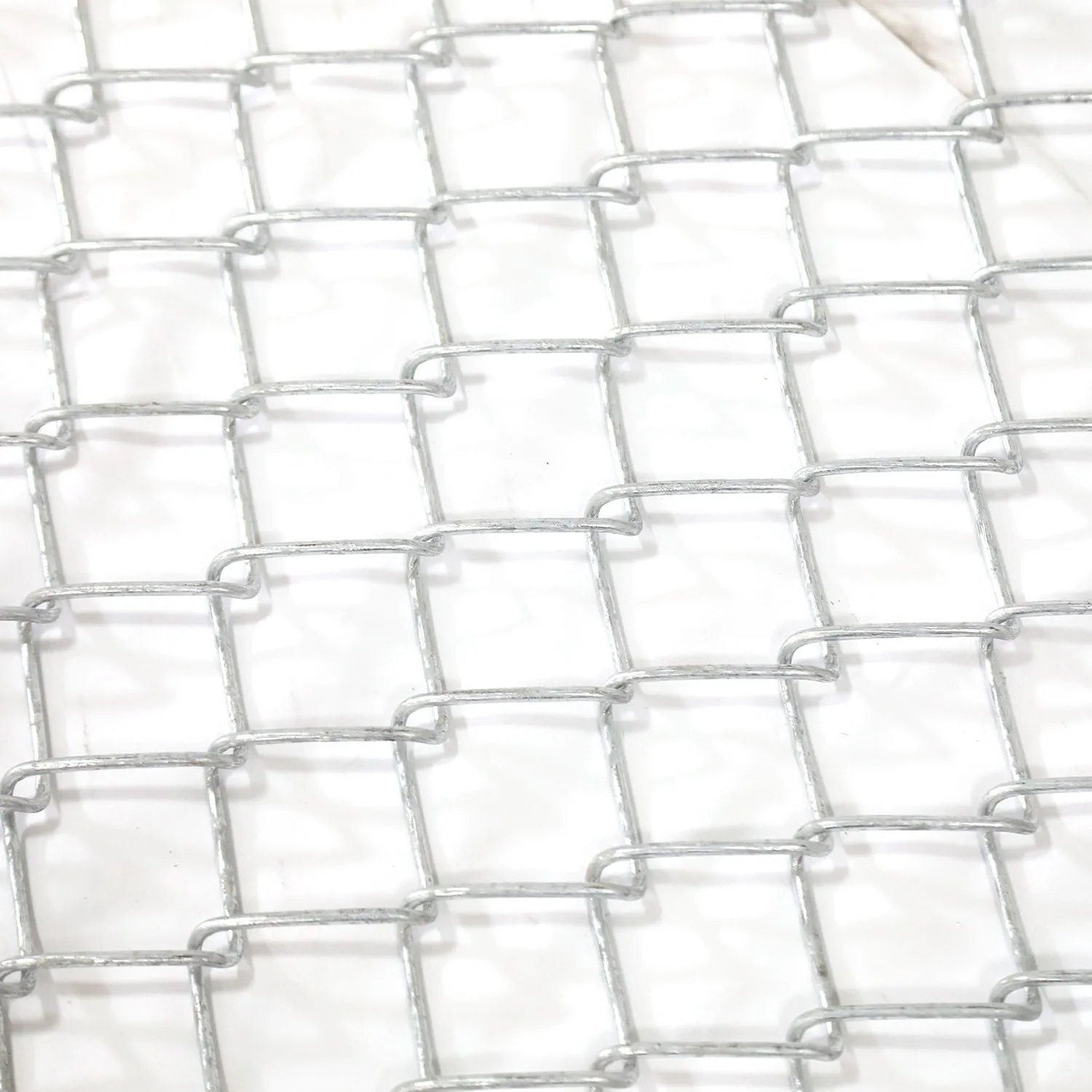

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA