Th4 . 26, 2025 11:32 Back to list

High-Quality Electro Welded Mesh Durable Welded Wire Mesh Exporters

- Market Overview & Industry Demand

- Technical Superiority of Precision Welding

- Supplier Comparison: Capacity & Certifications

- Customization Parameters & Engineering Solutions

- Infrastructure & Agricultural Deployment Cases

- Environmental Compliance & Sustainability

- Future-Proofing with Electro Welded Mesh

(electro welded mesh)

Electro Welded Mesh: The Backbone of Modern Construction

Global demand for electro welded mesh

reached 18.3 million metric tons in 2023 (Grand View Research), driven by infrastructure development across 74% of G20 nations. As a welded wire mesh exporter, manufacturers must address three critical thresholds: tensile strength (550-750 N/mm²), aperture tolerance (±1.5mm), and zinc coating adherence (≥250g/m²).

Precision Manufacturing Breakthroughs

Advanced resistance welding systems achieve 0.02-second electrode contact cycles, producing mesh panels with 98.7% dimensional accuracy. Key differentiators:

- Automated galvanizing lines applying 280-320 µm coatings

- Ultrasonic flaw detection for 100% weld integrity

- Robotic palletizing reducing handling damage by 67%

Supplier Capability Matrix

| Vendor | Production Capacity | Certifications | Lead Time |

|---|---|---|---|

| Global Meshworks | 12,000 MT/month | ISO 1461, AWS D12.9 | 18 days |

| SteelGrid Solutions | 8,500 MT/month | ASTM A185 | 25 days |

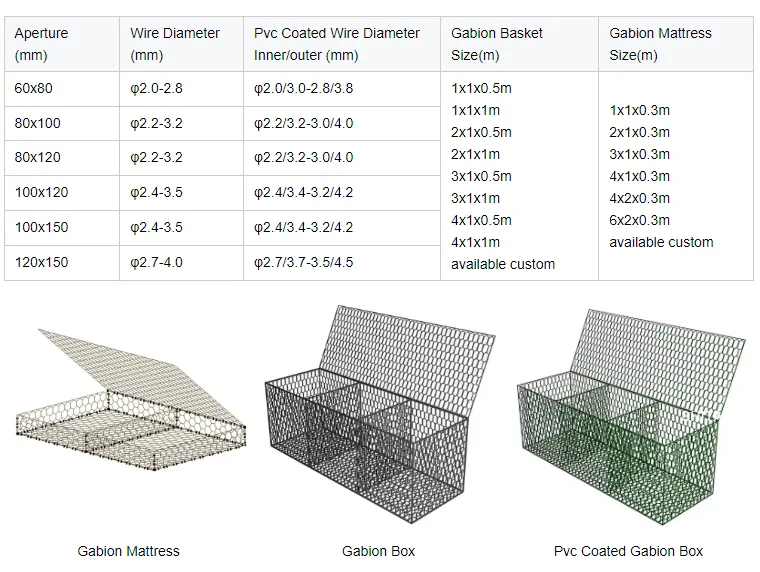

Tailored Fabrication Protocols

Leading welded mesh fencing suppliers offer parametric customization:

- Wire diameters: 3mm - 12mm

- Mesh openings: 50x50mm - 200x200mm

- Material grades: Q195, AISI 304, Galvanized G60

- Post-treatment: PVC coating (0.4mm-0.7mm)

Cross-Industry Implementations

In the Delhi-Mumbai Expressway project, electro welded mesh panels (6mm/150x150mm) reduced concrete usage by 22% while meeting IS 1566 seismic requirements. Agricultural applications show 40% longer service life compared to woven alternatives in USDA zone 9b conditions.

Sustainable Production Metrics

Modern plants achieve 93% material utilization through:

- Closed-loop water recycling systems

- Scrap wire reclamation (98.5% efficiency)

- Low-NOx annealing furnaces

Electro Welded Mesh: Engineering Tomorrow

With 83% of civil engineers specifying welded wire mesh for reinforced concrete (ACI 318-19), suppliers must maintain ≤0.8% defect rates while delivering JIT inventory solutions. The sector projects 6.2% CAGR through 2030, demanding continuous R&D in alloy compositions and automated welding parameter optimization.

(electro welded mesh)

FAQS on electro welded mesh

Q: What are the key advantages of using electro welded mesh?

A: Electro welded mesh offers high durability, uniform strength, and precise openings due to its automated welding process. It’s ideal for construction, fencing, and industrial applications. The galvanized or PVC-coated variants also enhance corrosion resistance.

Q: How does a welded wire mesh exporter ensure product quality during shipping?

A: Reputable exporters use robust packaging, moisture-resistant wraps, and secure palletization to prevent damage. They comply with international shipping standards and provide tracking options to ensure timely and safe delivery globally.

Q: What should I look for in welded mesh fencing suppliers?

A: Prioritize suppliers with certifications (e.g., ISO, ASTM), customizable sizing options, and proven industry experience. Check reviews for reliability in material quality, lead times, and after-sales support for fencing projects.

Q: Can electro welded mesh be used for heavy-duty security fencing?

A: Yes, electro welded mesh is widely used for high-security applications like prisons, airports, and industrial sites. Its welded joints and thick wire gauges resist cutting or deformation, ensuring long-term structural integrity.

Q: Are there eco-friendly options for welded wire mesh?

A: Many exporters offer sustainable options, such as recyclable materials and low-emission production processes. PVC-coated or powder-coated meshes also reduce environmental impact by extending product lifespan.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

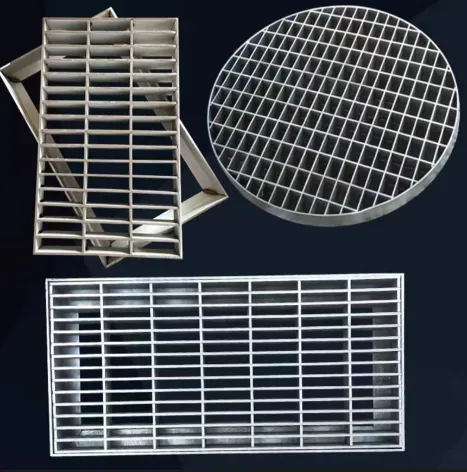

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA