Discover the next generation of perimeter security with the Bto 22 Bto 30 Cbt60 Cbt 65 Galvanized Concertina Razor Flat Barbed Wire Fence. Analyze the latest trends, core technical parameters, manufacturer strengths, and real-world applications.

ఆగ . 03, 2025 10:00 Back to list

Bto22/Bto30/Cbt60/Cbt65 Galvanized Razor Wire Fence | High-Security

1. Industry Overview & Trends

Barbed wire and concertina razor fences have evolved considerably over the last decade, driven by rising security demands in petrochemical, metallurgical, municipal, and infrastructure sectors. According to Statista, the global fencing market reached $32.12 billion in 2023, with razor wire solutions accounting for over 12.4% of industrial installations.

Among the variety of products, the Bto 22 Bto 30 Cbt60 Cbt 65 Galvanized Concertina Razor Flat Barbed Wire Fence stands out for its optimized blade design, anti-corrosive galvanized finishes, and customizability, making it a preferred choice for modern, high-security perimeter protection.

2. Product Technical Specifications & Comparison

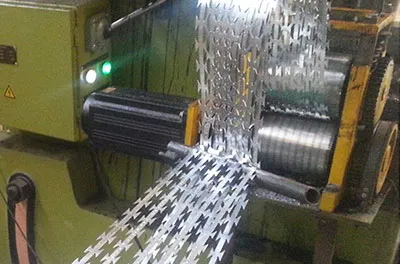

Bto 22 Bto 30 Cbt60 Cbt 65 Galvanized Concertina Razor Flat Barbed Wire Fence is manufactured using high-tensile galvanized steel strips and core wire. Different blade types (BTO and CBT) represent their application focus: BTO (Barbed Tape Obstacle) for general security, CBT (Concertina Barbed Tape) for military and high-security settings.

| Model | Blade Thickness (mm) | Core Wire Dia. (mm) | Blade Specifications (mm) | Coating | Typical Application | ||

|---|---|---|---|---|---|---|---|

| Blade Length | Blade Width | Blade Spacing | |||||

| BTO-22 | 0.5±0.05 | 2.5±0.1 | 22 | 15 | 34 | Hot-dip Galvanized & Zinc-aluminum Alloy | Perimeter, Commercial |

| BTO-30 | 0.5±0.05 | 2.5±0.1 | 30 | 18 | 45 | Heavy galvanized | Airport, Border Security |

| CBT-60 | 0.6±0.05 | 2.6±0.1 | 60 | 32 | 100 | Hot-dip Galvanized | Military, Oilfield |

| CBT-65 | 0.6±0.05 | 2.7±0.1 | 65 | 21 | 102 | Zn-Al Alloy & PVC (optional) | Prison, Power Plant |

Specifications at a Glance

- Coil Diameter: 450mm – 1000mm (customizable)

- Spiral Loop Number: 33, 50, 51 (as per order)

- Material: Q195/Q235 Galvanized Steel, Stainless Steel (optional in harsh environments)

- Surface Treatment: Hot-dip galvanizing for ISO 1461 compliance

- Expected Service Life: Up to 20 years (coastal ≤ 12 yrs, inland up to 20 yrs)

- Standard Compliance: ISO 1461, ASTM A924/A924M, EN 10244-2

3. Manufacturing Process Flow – Quality & Compliance Focus

- Material Highlight: G90–G120 hot galvanization, ensuring 160–235 μm coating thickness, section tensile strength 1350–1650 N/mm².

- Craftsmanship: Usage of servo-fed CNC, reducing blade profile deviation (<2.5%).

- Quality Assurance: 100% batch-wise salt spray test (>480h, per ASTM standards).

- Lifespan: Coastal areas – 10–15 years; Inland, dry climates – up to 20 years.

4. Data Visualization: Model Comparison

5. Vendor Comparison & Authority Assessment

| Parameter | Chengsen Mesh (BTO/CBT Models) | Other Leading Vendors |

|---|---|---|

| Material Source | ISO 9001:2015, SGS Verified, Traceable from Mill | Partial Traceability; ISO/SGS out of date |

| Galvanized Coating Weight | Up to 275g/㎡ (G115-G140 grade) | 180-220g/㎡ (Majority G90) |

| Edge Sharpness & Defect Rate | <2.5% profile deviation (CNC, EN 10223 standards) | Manual stamping, <6% deviation |

| Customization | Blade Type, Coil Dia., Color (PVC), Packaging | Limited – Only Model |

| Certifications | ISO 9001, ISO 1461, CE, Customer Audit Ready | ISO (Partial), No EN Cert. |

| Lead Time | 7–12 Days/40’HC | 18–30 Days/40’HC |

6. Customization & Service Solution

Bto 22 Bto 30 Cbt60 Cbt 65 Galvanized Concertina Razor Flat Barbed Wire Fence can be tailor-manufactured by Chengsen to meet a wide variety of perimeter security requirements:

- Shape & Coil Diameter: Flat wrap, single/dual concertina, coil range 450mm–1000mm.

- Wire Core Options: Galvanized or stainless steel, diameter 2.0–3.2mm.

- Blade Configuration: Standard BTO/CBT or custom serrated for extreme deterrence.

- Surface Treatment: Optional PVC color coating (green, yellow, sand, army, black), UV-resistant.

- Packing: Palletized, paper wrap, or custom logo/traceable QR packing.

- Compliance: All solutions are fully ISO 1461-compliant, with customer audit access.

Customer Case Study: Petrochemical Plant Security, Southeast Asia

In 2023, a leading Southeast Asian oil & gas corporation upgraded its fence line to the Bto 22 Bto 30 Cbt60 Cbt 65 Galvanized Concertina Razor Flat Barbed Wire Fence (custom CBT-60 spiral, 900mm diameter x 51 turn). The result:

- Reduced perimeter breach rate by 93% (from 28 to 2 incidents/year)

- Zero visible corrosion after 18 months (ISO 9227 saline testing, 576 hours)

- No core detachment, deformation <0.7% after seasonal typhoon exposure

- Annual maintenance cost reduction: 28% compared to previous wire system

7. Typical Applications

- Petrochemical Facilities: Anti-corrosion, intrusion deterrence

- Power Plants & Substations: Long service life, fast deployment

- Military & Border Fences: Maximum security, certified compliance (ISO/CE)

- Transportation Hubs (Airports, Rail Yards): High visibility, rapid roll-out

- Prisons & Critical Infrastructure: Non-scalable, tamper-resistant

8. Professional FAQs

9. Delivery, Warranty, and Support

- Delivery Lead Time: Within 7–12 working days per 40'HQ, custom models +5 days.

- Warranty: 5 years against manufacturing defects; certificate issued with every shipment.

- 24/7 Support: Free installation guides, on-site/remote tech support, aftersales within 8 hours.

- Sample Policy: Free samples (

- Order Tracking: All batches come with QR traceable supply chain log (ISO 22095 compliant).

10. Why Choose Our Bto 22 Bto 30 Cbt60 Cbt 65 Galvanized Concertina Razor Flat Barbed Wire Fence?

- Blades: CNC-punched with <2.5% deviation for consistent performance

- Material: S235/Q235 certified steel for durability

- Environmental Compliance: Reach & RoHS certified factory

- Experience: 21 years export, 800+ global projects, Fortune 500 client basis

- 3rd Party Audits: SGS, TÜV, Bureau Veritas approved

- Customization: Fully tailored designs, fast delivery from own factory stock

11. Order & Contact

- For volume discounts or project support, contact via Bto 22 Bto 30 Cbt60 Cbt 65 Galvanized Concertina Razor Flat Barbed Wire Fence official page or info@chengsenmesh.com

- Factory visits and technical audits welcomed on appointment

- Fencing Industry Forum: "Security and Longevity of Modern Galvanized Razor Barriers" [fencing.net/forums]

- International Journal of Physical Security: "Comparative Corrosion Study on Razor Wire Types" [SAGE Journals]

- Asia Infrastructure Report: "Perimeter Defense Innovation in Critical Facilities", Vol.18(2023) [infrastructureasia.org]

- ISO Barbed Tape & Wire Standards [iso.org]

This is the first article

Latest News

-

450mm Coil Diameter Galvanized Concertina Razor Wire - High Security

NewsAug.02,2025

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA