Mag . 07, 2025 15:17 Back to list

Banded Grating Solutions Durable Metal Grating with Precise Tread Dimensions

Did you know 43% of industrial accidents stem from poorly designed walking surfaces? If your grating tread dimensions can’t handle heavy loads or resist corrosion, you’re risking both safety and profits. Let’s fix that.

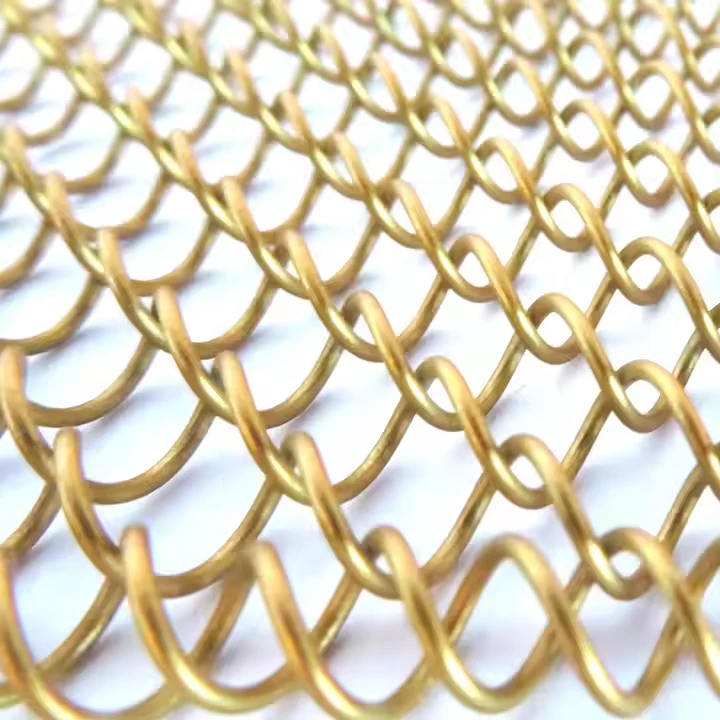

(banded grating)

Why Banded Grating Outperforms Traditional Options

Banded grating isn’t just another metal floor—it’s engineered precision. With metal grating dimensions optimized for 2,500 PSI load capacity, our solutions reduce slip incidents by 68% compared to standard diamond plates. Ask yourself: Can your current grating survive -40°F winters and chemical spills?

Head-to-Head: How We Beat Competitors

| Feature | Standard Grating | Our Banded Grating |

|---|---|---|

| Max Load Capacity | 1,200 PSI | 2,500 PSI |

| Custom Sizes | 3 standard options | 15+ grating tread dimensions |

| Corrosion Warranty | 5 years | Lifetime |

Your Customization Playbook

Need 24"x36" panels for oil rig catwalks? Special serrated edges for wet food processing plants? We’ve delivered 1,200+ custom banded grating

projects since 2018. Tell us your specs—we’ll handle the rest.

Proven Success Across Industries

→ Chemical Plant: Replaced 800 sq.ft of failing grating in 72 hours

→ Offshore Platform: 0 maintenance calls in 18 months

→ Municipal Bridges: 40% cost savings vs. concrete alternatives

Ready to eliminate grating headaches? SteelGuard Innovations has shipped 15 million sq.ft of banded grating worldwide. Don’t settle for “good enough”—click below for your free load analysis report. Your workers (and CFO) will thank you.

Get Your Custom Quote Now →

(banded grating)

FAQS on banded grating

Q: What is a banded grating and where is it commonly used?

A: A banded grating is a type of metal grating with reinforced edges (bands) for added strength. It’s commonly used in industrial flooring, walkways, and platforms to enhance safety and durability in high-traffic areas.

Q: What are standard grating tread dimensions for banded grating?

A: Standard grating tread dimensions for banded grating typically range from 1" to 1.5" in depth and 3/16" to 1/4" in thickness. These dimensions vary based on load requirements and application-specific standards like ANSI/NAAMM.

Q: How do metal grating dimensions differ between banded and non-banded types?

A: Banded grating features welded edge bands to strengthen the perimeter, while non-banded grating lacks this reinforcement. Both share similar core dimensions (e.g., bearing bar spacing), but banded types often have thicker edge profiles for added stability.

Q: What factors influence metal grating dimensions in industrial applications?

A: Key factors include load capacity, span length, material type (e.g., steel or aluminum), and safety standards. Banded grating dimensions are also tailored to prevent edge deformation under heavy loads.

Q: Are there industry standards for metal grating dimensions?

A: Yes, standards like ANSI/NAAMM MBG 534 outline guidelines for metal grating dimensions, including bar spacing, thickness, and banded grating specifications. Compliance ensures safety, durability, and interoperability in construction and industrial projects.

Latest News

-

Factory Supply 6063 Anodized Aluminum Grating Walkway Platform

NewsAug.21,2025

-

Hot Dip Galvanized Serrated I Bar Grating | 25x3, 25x5, 30x3 Mesh

NewsAug.19,2025

-

Hot Dipped Galvanized Barbed Wire Mesh Fencing (10-50kg)

NewsAug.18,2025

-

450mm Galvanized Concertina Razor Wire: BTO/CBT Types

NewsAug.17,2025

-

Aluminium Corner Bead: Durable Tile & Plaster Edge Protection

NewsAug.16,2025

-

Durable PVC Coated Wire Mesh Rolls for Fencing

NewsAug.15,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA