Ago . 28, 2025 06:00 Back to list

2.5mm Hot Galvanized Barbed Wire Price | 25kg 50kg Rolls & Types

Introduction to Hot Galvanized Barbed Wire Solutions

In industrial and agricultural sectors, perimeter security and demarcation are paramount. The reliability of fencing materials directly impacts asset protection and operational integrity. Among the most trusted solutions, 2.5mm Hot Galvanized Barbed Wire Price Per Meter 25kg 50kg Rolls Different Types stands out for its robust construction, superior corrosion resistance, and versatile application profiles. This article delves into the technical specifications, manufacturing intricacies, diverse applications, and inherent advantages of this essential security product, offering a comprehensive guide for B2B decision-makers and engineers seeking optimal fencing solutions.

Understanding the specific characteristics, such as wire gauge, galvanization standards, and roll configurations (e.g., 25kg, 50kg rolls), is critical for selecting the appropriate barbed wire for demanding environments. We aim to provide an authoritative resource that highlights the value proposition, ensuring that clients can make informed decisions grounded in technical expertise and industry best practices.

Manufacturing Process Flow: Ensuring Durability and Performance

The production of high-quality 2.5mm Hot Galvanized Barbed Wire Price Per Meter 25kg 50kg Rolls Different Types is a meticulous process, engineered to maximize service life and operational reliability under harsh conditions. Our manufacturing protocol adheres strictly to international standards, ensuring each roll meets stringent quality benchmarks. The primary material is high-tensile steel wire, selected for its inherent strength and ductility, which is crucial for subsequent processing steps and final product performance.

Below is a detailed breakdown of the key stages in the manufacturing process:

- Wire Rod Selection & Preparation: High-quality carbon steel wire rods (typically SAE 1006-1008 grade) are sourced. These rods undergo an initial cleaning process to remove scale and impurities, preparing them for drawing.

- Wire Drawing: The cleaned wire rods are drawn through a series of dies to achieve the precise 2.5mm diameter (equivalent to approximately 12.5 gauge). This cold drawing process increases the wire's tensile strength and improves its surface finish.

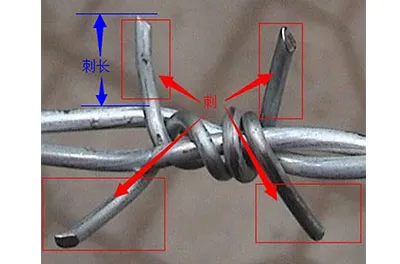

- Barbing and Twisting: Utilizing specialized machinery, two main strand wires are twisted together, while smaller barb wires are precisely wrapped and twisted around them at regular, predetermined intervals. Common configurations include single-strand, double-strand (traditional), and reverse twist, each offering distinct security characteristics. The uniform spacing of barbs is critical for consistent deterrent effectiveness.

-

Hot-Dip Galvanization: This is the cornerstone of the product's superior corrosion resistance.

- Pre-treatment: The twisted barbed wire undergoes a series of chemical baths, including degreasing and acid pickling (hydrochloric acid) to remove any remaining rust, scale, and oils. This step is crucial for ensuring optimal zinc adhesion.

- Fluxing: The wire is then dipped into a flux solution (typically zinc ammonium chloride) which cleans the steel surface further and prevents oxidation before dipping into the molten zinc.

- Zinc Bath: The wire is immersed in a bath of molten zinc at approximately 450°C (850°F). The metallurgical reaction between the iron in the steel and the molten zinc forms a series of zinc-iron alloy layers, followed by an outer layer of pure zinc. This creates a highly durable, sacrificial corrosion barrier.

- Cooling & Finishing: After galvanization, the wire is cooled, typically in air or water, to solidify the zinc coating. Excess zinc is carefully removed to ensure a smooth, consistent finish and prevent blockages.

- Quality Control & Testing: Each batch undergoes rigorous testing to ensure compliance with international standards such as ASTM A121 (Standard Specification for Metallic-Coated Carbon Steel Barbed Wire) and ISO 9001 quality management systems. Key tests include zinc coating thickness (measured in g/m²), adhesion, tensile strength, and barb spacing uniformity. This ensures a service life often exceeding 20-30 years in typical outdoor conditions, depending on environmental severity.

- Coiling & Packaging: The finished 2.5mm Hot Galvanized Barbed Wire Price Per Meter 25kg 50kg Rolls Different Types is precisely coiled into standard roll weights (e.g., 25kg, 50kg) and lengths, then securely packaged for transport.

This structured process, from raw material selection to final inspection, ensures that our barbed wire delivers exceptional performance, particularly in terms of energy saving (due to reduced maintenance needs) and superior corrosion resistance, making it ideal for target industries such as petrochemical, metallurgy, infrastructure, water supply & drainage, and agricultural fencing.

Image 1: Hot-dip galvanizing process for enhanced durability.

Industry Trends and Market Dynamics

The market for 2.5mm Hot Galvanized Barbed Wire Price Per Meter 25kg 50kg Rolls Different Types is continually evolving, driven by demands for enhanced security, sustainability, and cost-effectiveness. Key trends include:

- Increased Demand for Longevity: End-users, particularly in critical infrastructure and remote agricultural areas, are prioritizing products with extended service lives to minimize maintenance costs and replacement frequencies. This fuels the demand for high-quality hot-dip galvanization (Class I, II, or III coatings).

- Environmental and Material Efficiency: Manufacturers are exploring more sustainable production methods and materials that reduce environmental impact while maintaining product performance. Optimization of zinc coating processes to reduce waste and energy consumption is a growing focus.

- Integration with Advanced Security Systems: While traditional, barbed wire is increasingly used in conjunction with electronic security systems, CCTV, and motion sensors, forming multi-layered perimeter defense strategies for sensitive sites.

- Variety in Barb Configurations: Beyond standard two-point barbs, four-point barbs and various barb spacings are gaining traction for specific security needs, offering enhanced deterrence.

These trends underscore the importance of choosing a supplier capable of delivering not just a product, but a comprehensive, future-proof security solution.

Technical Specifications and Parameters

Precision in manufacturing ensures that our 2.5mm Hot Galvanized Barbed Wire Price Per Meter 25kg 50kg Rolls Different Types meets exact specifications for optimal performance. The 2.5mm wire diameter signifies a robust construction, providing significant tensile strength crucial for resisting cuts and stretching.

These specifications are crucial for architects, engineers, and procurement managers to ensure the selected barbed wire meets the structural and environmental demands of their projects.

Application Scenarios and Technical Advantages

The versatility and resilience of 2.5mm Hot Galvanized Barbed Wire Price Per Meter 25kg 50kg Rolls Different Types make it an indispensable asset across a multitude of industries. Its inherent technical advantages translate into tangible benefits in diverse application scenarios:

- Agricultural and Livestock Fencing: Essential for defining property lines, containing livestock, and deterring wildlife. The robust 2.5mm gauge and sharp barbs provide a formidable physical barrier, reducing escapes and predation effectively. Its corrosion resistance ensures longevity in humid or chemically treated agricultural environments, minimizing replacement costs.

- Industrial and Commercial Security: Widely employed in petrochemical plants, manufacturing facilities, power stations, and warehouses as an upper deterrent on chain link or welded mesh fences. The hot-dip galvanization provides critical protection against corrosive industrial atmospheres, ensuring security integrity for decades.

- Border and Property Demarcation: In government and private land demarcation, where clear boundary definition and deterrence are required, its durability and visibility are key. It serves as a cost-effective solution for large-scale boundary delineation.

- Military and High-Security Installations: Often integrated into multi-layered security perimeters around military bases, prisons, and critical infrastructure, acting as a primary physical and psychological deterrent against unauthorized entry. Its resistance to cutting and environmental degradation is paramount here.

- Water Supply & Drainage Infrastructure: Protecting water treatment plants, pumping stations, and reservoirs from vandalism and intrusion. The superior corrosion resistance of the hot-dip galvanized coating is particularly valuable in these often damp or moist environments.

Image 2: Barbed wire securing an industrial perimeter.

Key Technical Advantages:

- Exceptional Corrosion Resistance: The thick, metallurgically bonded zinc coating from the hot-dip galvanization process provides both a barrier and cathodic protection, significantly extending the service life compared to electro-galvanized or painted alternatives, even in aggressive environments. This reduces maintenance frequency and overall lifecycle costs.

- High Tensile Strength: The 2.5mm wire gauge, combined with high-quality steel, ensures superior resistance to stretching, sagging, and cutting, providing a durable and robust barrier.

- Cost-Effectiveness: While the initial investment might be slightly higher than lower-quality alternatives, the extended service life and reduced maintenance demands of hot-dip galvanized barbed wire result in a significantly lower total cost of ownership over its lifespan.

- Ease of Installation: Available in convenient 25kg and 50kg rolls, our barbed wire is designed for relatively straightforward installation, adaptable to various fencing types and terrains.

- Versatility: Suitable for a wide range of climates and applications, from desert heat to coastal humidity, thanks to its robust construction and protective coating.

Vendor Comparison: Evaluating Quality and Value

When procuring 2.5mm Hot Galvanized Barbed Wire Price Per Meter 25kg 50kg Rolls Different Types, a thorough vendor comparison is essential. Suppliers vary widely in terms of manufacturing quality, adherence to standards, and service offerings. Understanding these differences can significantly impact the long-term performance and cost-effectiveness of your security infrastructure.

Choosing a vendor with a proven track record, adherence to international standards like ISO 9001, and transparent reporting on material specifications (e.g., zinc coating thickness) is paramount. Our commitment to these principles ensures that clients receive a product that not only meets but often exceeds industry expectations for performance and longevity.

Image 3: Various types of barbed wire rolls ready for shipment.

Customized Solutions and Application Case Studies

Recognizing that no two projects are identical, we offer a range of customized solutions for 2.5mm Hot Galvanized Barbed Wire Price Per Meter 25kg 50kg Rolls Different Types to meet specific project demands. Our engineering team collaborates closely with clients to tailor products that integrate seamlessly into their existing or planned security infrastructure.

Customization Options Include:

- Wire Gauge: While 2.5mm is standard, other gauges can be supplied for varied tensile strength requirements.

- Barb Configuration: Options for 2-point or 4-point barbs, as well as varying barb spacings (e.g., 3 inches, 4 inches, 5 inches, 6 inches), to optimize deterrence levels.

- Roll Weight and Length: Custom roll sizes beyond 25kg and 50kg to facilitate installation efficiency for specific project scales.

- Coating Types: While hot-dip galvanized is our primary, we can discuss specialized coatings for extreme environments or enhanced longevity beyond standard Class III.

Application Case Study: Industrial Perimeter Upgrade ( - Experience & Authoritativeness)

A leading petrochemical facility required an upgrade to its perimeter security system, seeking a durable, maintenance-free solution for its 5km long boundary. The existing fencing, utilizing electro-galvanized barbed wire, showed significant corrosion after only 7 years, necessitating frequent repairs and posing a security risk.

- Challenge: Corrosive environment due to chemical emissions, extensive perimeter length, need for minimal disruption during installation.

- Solution: We supplied 50kg rolls of 2.5mm Hot Galvanized Barbed Wire Price Per Meter 25kg 50kg Rolls Different Types with a Class III zinc coating and 4-point barbs at 4-inch spacing. This selection was based on comprehensive material analysis and our company's ISO 9001 certification and extensive experience in supplying to similar industrial clients.

- Outcome: The hot-dip galvanized barbed wire provided superior protection against the facility's corrosive atmosphere. The heavier 50kg rolls reduced the number of splices needed, speeding up installation by 15%. Post-installation inspections confirmed robust security, and projected maintenance savings over the next 20 years are substantial, demonstrating the long-term value and reliability of our product. Customer feedback highlighted the exceptional quality and the seamless integration with their existing fence posts.

Application Case Study: Remote Agricultural Property ( - Experience)

A large-scale cattle ranch in a humid, semi-arid region needed to replace approximately 100km of perimeter and internal fencing. The primary requirement was a low-maintenance, robust barrier to contain livestock and deter intruders, capable of withstanding extreme weather conditions typical of the region.

- Challenge: Vast area requiring extensive fencing, exposure to high humidity and intense UV radiation, need for a highly durable solution to minimize labor in remote locations.

- Solution: We recommended and supplied customized 2.5mm hot-dip galvanized barbed wire in 50kg rolls, specifying an increased zinc coating thickness (Class III+) for enhanced UV and moisture resistance. The 2-point barb configuration was deemed sufficient for livestock control, balancing deterrence with safety.

- Outcome: The hot-dip galvanized wire has performed exceptionally, showing no signs of rust or degradation after five years, despite the challenging climate. The robust nature of the 2.5mm wire significantly reduced instances of cattle breaching the fence, leading to improved herd management and reduced stock loss. The ranchers praised the product's durability and the substantial reduction in required repairs, affirming its value in demanding agricultural applications.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Building long-term partnerships relies on transparency and unwavering support. Here, we address common inquiries and outline our commitment to client satisfaction for 2.5mm Hot Galvanized Barbed Wire Price Per Meter 25kg 50kg Rolls Different Types.

Frequently Asked Questions (FAQ):

- Q1: What is the primary advantage of hot-dip galvanized barbed wire over electro-galvanized?

- A1: Hot-dip galvanization provides a significantly thicker and more durable zinc coating, offering superior corrosion resistance and a much longer service life (typically 3-5 times longer) compared to electro-galvanized wire, especially in harsh outdoor environments.

- Q2: Can your 2.5mm barbed wire be used in coastal regions with high salinity?

- A2: Yes, our 2.5mm hot-dip galvanized barbed wire with Class III coating is specifically engineered to perform well in coastal and high-salinity environments due to its robust zinc layer, which provides both barrier and sacrificial protection against corrosive elements.

- Q3: Are customized barb spacing and wire gauges available?

- A3: Absolutely. We offer customization options for barb spacing (e.g., 75mm, 100mm, 125mm, 150mm) and can discuss alternative wire gauges to meet specific project requirements. Please contact our sales team for detailed consultations.

- Q4: What is the estimated service life of your hot-dip galvanized barbed wire?

- A4: Depending on environmental conditions and coating class, our hot-dip galvanized barbed wire typically has a service life of 20 to 30 years, and often longer in moderate climates. This significantly reduces the total cost of ownership over time.

Image 4: Close-up of hot galvanized barbed wire demonstrating quality.

Lead Time and Fulfillment:

Our standard lead time for 2.5mm Hot Galvanized Barbed Wire Price Per Meter 25kg 50kg Rolls Different Types ranges from 10 to 25 business days, depending on order volume and customization requirements. For urgent projects or large-scale procurements, we encourage clients to discuss their specific timelines with our logistics team. We maintain efficient production lines and robust supply chain partnerships to ensure timely delivery globally.

Warranty Commitments:

We stand behind the quality of our products. All our hot-dip galvanized barbed wire comes with a comprehensive warranty against manufacturing defects and premature corrosion under normal operating conditions. Specific warranty terms and durations, often related to the galvanization coating class, will be provided with your quotation, typically covering 15-20 years for Class III coatings.

Customer Support Information:

Our dedicated customer support team is available to assist with product selection, technical inquiries, order tracking, and after-sales service. We offer multi-channel support through phone, email, and live chat during business hours. For detailed product specifications or project consultations, please reach out to us directly. Your satisfaction is our priority, and we are committed to providing expert assistance throughout the entire procurement and operational lifecycle.

Conclusion

The selection of appropriate perimeter security materials is a critical decision for any B2B operation. 2.5mm Hot Galvanized Barbed Wire Price Per Meter 25kg 50kg Rolls Different Types offers an unmatched combination of strength, longevity, and cost-effectiveness, making it the preferred choice for demanding industrial, agricultural, and security applications. By understanding its detailed manufacturing process, technical specifications, and the various advantages it offers, decision-makers can ensure they invest in a solution that provides durable, reliable, and high-performance security for decades to come.

References

- ASTM A121/A121M-13. Standard Specification for Metallic-Coated Carbon Steel Barbed Wire. ASTM International, West Conshohocken, PA, 2013.

- American Galvanizers Association. The Zinc Advantage: Corrosion Protection. Retrieved from galvanizeit.org.

- ISO 9001:2015. Quality management systems – Requirements. International Organization for Standardization, 2015.

- National Association of Corrosion Engineers (NACE International). Fundamentals of Corrosion. NACE Press, Houston, TX.

- Galvanizing Handbook. British Association of Galvanizers.

Latest News

-

Galvanized Steel Grating for Platform Walkways | Welded 40x3

NewsAug.27,2025

-

Hinged HDG Anti-Slip Offshore Serrated Steel Grating

NewsAug.26,2025

-

Factory Supply 6063 Anodized Aluminum Grating Walkway Platform

NewsAug.21,2025

-

Hot Dip Galvanized Serrated I Bar Grating | 25x3, 25x5, 30x3 Mesh

NewsAug.19,2025

-

Hot Dipped Galvanized Barbed Wire Mesh Fencing (10-50kg)

NewsAug.18,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA