Agu . 10, 2025 07:00 Back to list

Durable Q235 Galvanized Press-Locked Grating for Walkway Platforms

The Indispensable Role of Q 235 Galvanized Press Locked Steel Grating for Walkway Platforms in Modern Industrial Infrastructure

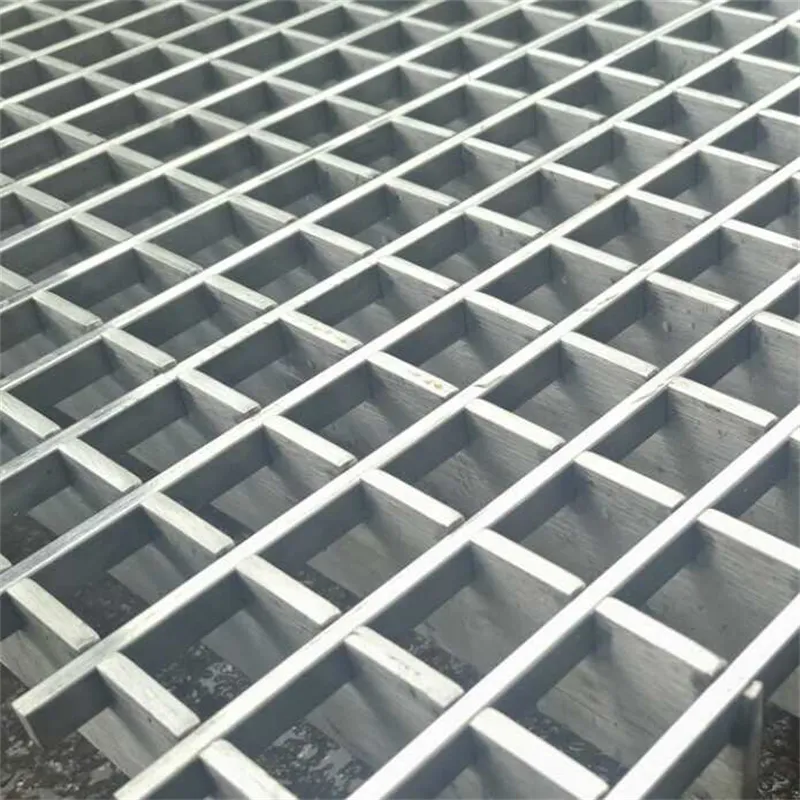

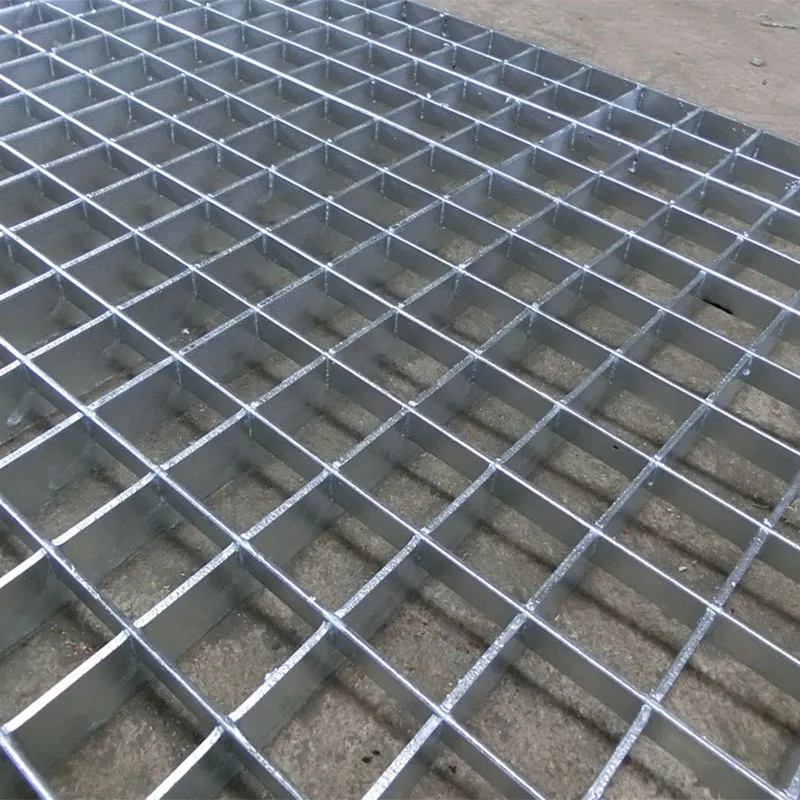

In the relentless pursuit of operational efficiency, safety, and durability within the diverse tapestry of industrial environments, the selection of critical infrastructure components stands paramount. Among these, Q 235 Galvanized Press Locked Steel Grating For Walkway Platform emerges as a foundational element, critical for creating robust, secure, and long-lasting access solutions. This specialized grating, fabricated from Q235 structural carbon steel, renowned for its excellent weldability and formability, undergoes a unique press-locking manufacturing process before being hot-dip galvanized to ensure unparalleled corrosion resistance and an extended service life. The intrinsic design of press-locked grating, characterized by interlocking bearing bars and cross bars, eliminates the need for welding at intersections, resulting in a product with superior structural integrity, aesthetic appeal, and remarkable strength-to-weight ratio. This innovative construction minimizes residual stresses, a common issue in welded gratings, thereby enhancing fatigue resistance and overall longevity, particularly in dynamic or high-vibration settings. The application spectrum for this material is vast and critical, ranging from elevated walkways and maintenance platforms in petrochemical refineries and power generation facilities to durable flooring in water treatment plants and architectural facades requiring both functionality and visual harmony. The choice of Q235 steel ensures a cost-effective yet high-performance base material that readily accepts the hot-dip galvanization process, providing a robust sacrificial coating that protects the underlying steel from rust and environmental degradation. The stringent manufacturing processes, often adhering to international standards like ISO 9001 for quality management and ASTM A123 for galvanization, ensure that each panel of Q 235 Galvanized Press Locked Steel Grating For Walkway Platform meets rigorous performance criteria for load-bearing capacity, slip resistance, and dimensional accuracy. Furthermore, the inherent open mesh design facilitates excellent light and air penetration, crucial for ventilation in confined industrial spaces and minimizing snow or debris accumulation in outdoor applications, thereby enhancing safety and operational continuity. As industries worldwide pivot towards more resilient and sustainable infrastructure solutions, the inherent recyclability of steel combined with the extended lifespan afforded by galvanization positions this grating as an environmentally responsible choice, reducing the need for frequent replacements and minimizing material consumption over the project lifecycle. This comprehensive analysis will delve into the nuanced technical parameters, sophisticated manufacturing processes, diverse application scenarios, and compelling advantages that collectively underscore why Q 235 Galvanized Press Locked Steel Grating For Walkway Platform is not merely a component but a strategic investment in the safety, efficiency, and longevity of industrial and commercial infrastructure.

Precision Manufacturing: The Detailed Process Behind Q 235 Galvanized Press Locked Steel Grating

The creation of high-quality Q 235 Galvanized Press Locked Steel Grating For Walkway Platform is a sophisticated manufacturing endeavor that combines material science, precision engineering, and robust quality control. The process commences with the meticulous selection of Q235 steel, a structural carbon steel specified by Chinese standard GB/T 700, known for its optimal balance of strength, ductility, and excellent weldability, making it an ideal candidate for grating applications. This material's chemical composition and mechanical properties, including a minimum yield strength of 235 MPa and a tensile strength range of 370-500 MPa, are rigorously checked upon receipt to ensure compliance with design specifications and industry standards. The initial stage involves cutting the flat steel bars, which serve as bearing bars, and the cross bars to precise dimensions using automated high-speed cutting machines, ensuring dimensional accuracy crucial for the subsequent press-locking phase. Unlike traditional welded grating, which relies on a fusion process, press-locked grating leverages extreme hydraulic pressure to force the notched cross bars into pre-punched slots in the bearing bars. This intricate cold-forming process creates a robust mechanical interlock without the need for heat, thus preserving the inherent strength and structural integrity of the steel and avoiding the heat-affected zones common in welding that can reduce material strength and introduce residual stresses. The controlled pressure applied during locking ensures a tight, flush fit, creating a grating panel that is exceptionally strong, rigid, and torsionally resistant, minimizing deflection under load and enhancing durability. Following the press-locking, the raw grating panels undergo rigorous inspection for dimensional accuracy, flatness, and the integrity of each locked joint, often employing automated vision systems and manual checks to detect any imperfections. The final, critical stage is hot-dip galvanization, a process adhering to standards such as ASTM A123 (Standard Specification for Zinc Coatings on Iron and Steel Products) or ISO 1461 (Hot-dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods). The grating panels are first thoroughly cleaned through pickling (acid bath) to remove rust, scale, and contaminants, followed by fluxing to prepare the surface for bonding with zinc. They are then immersed in a bath of molten zinc at approximately 450°C (840°F). During immersion, the molten zinc metallurgically bonds with the steel, forming a series of highly resistant zinc-iron alloy layers, topped by a pure zinc layer. This coating provides a superior barrier protection against corrosion and cathodic protection, where the zinc sacrifices itself to protect the underlying steel even if scratched, significantly extending the service life of the Q 235 Galvanized Press Locked Steel Grating For Walkway Platform. The thickness of the galvanized coating is meticulously measured using magnetic or eddy current gauges, typically requiring a minimum average thickness as per relevant standards to ensure long-term performance in corrosive environments. This entire manufacturing chain, from raw material inspection to the final galvanization and quality checks, is overseen by stringent quality management systems, often certified to ISO 9001, guaranteeing a product that not only meets but often exceeds the demanding performance expectations of industrial clients globally.

Unpacking Technical Specifications: Performance Metrics of Q 235 Galvanized Press Locked Steel Grating

For B2B decision-makers and technical personnel, a deep understanding of the technical parameters and performance metrics of Q 235 Galvanized Press Locked Steel Grating For Walkway Platform is paramount for proper specification, design integration, and ensuring compliance with project requirements. The foundational material, Q235 steel, provides a robust base with well-defined mechanical properties: a minimum yield strength (ReL) of 235 MPa (34,000 psi) for thicknesses up to 16mm, and a tensile strength (Rm) ranging from 370 to 500 MPa (53,600 to 72,500 psi). Its elongation at fracture, typically 24-26%, indicates good ductility, allowing the steel to withstand deformation without fracturing, which is vital for load-bearing applications. The hot-dip galvanized coating, applied in accordance with international standards like ASTM A123/A123M or ISO 1461, ensures a minimum average coating thickness that varies based on the material's thickness; for example, sections 3/16 inch (4.8 mm) and over typically receive a minimum average coating of 610 g/m² (2.0 oz/ft²) or 85 µm (3.4 mils), providing exceptional corrosion protection that can last for decades in most atmospheric conditions. The configuration of the press-locked grating is defined by its bearing bar size (depth and thickness) and spacing, as well as the cross bar spacing. Common bearing bar depths range from 20mm to 100mm, with thicknesses typically from 3mm to 5mm. Standard bearing bar spacings often include 30mm, 40mm, and 60mm, while cross bar spacings typically range from 50mm to 100mm. These dimensions directly influence the grating's load-bearing capacity and open area percentage. For instance, a common specification might be 30x3mm bearing bars at 30mm spacing, interlocked with 10x2mm cross bars at 100mm spacing. The open area percentage, which impacts light and air passage, is typically between 60% and 80% for standard configurations. Load-bearing capacity is a critical metric, calculated using established engineering principles and often verified by physical load testing as per standards like ANSI/NAAMM MBG 531-09 (Metal Bar Grating Manual) or national building codes. For example, a 30x5mm bearing bar with 30mm spacing can support distributed loads exceeding 50 kN/m² over common span lengths, while point loads are also rigorously calculated. Slip resistance, crucial for safety on walkway platforms, is enhanced by the serrated top surfaces available as an option, which meet or exceed requirements of ADA (Americans with Disabilities Act) and OSHA (Occupational Safety and Health Administration) standards, particularly in wet or oily environments. The maximum panel size is usually limited by manufacturing capabilities and handling considerations, often up to 6000mm in length and 1000mm in width, though custom dimensions are routinely accommodated. The table below provides a representative overview of typical specifications for Q 235 Galvanized Press Locked Steel Grating For Walkway Platform, illustrating the interplay of dimensions and performance. These precise technical specifications allow engineers and project managers to select the optimal grating configuration for the specific load requirements, environmental conditions, and safety considerations of their industrial applications, ensuring both compliance and superior operational performance.

| Parameter | Typical Specifications | Relevant Standard/Property |

|---|---|---|

| Base Material | Q235 Carbon Steel | GB/T 700 |

| Yield Strength (Q235) | ≥ 235 MPa | GB/T 700 |

| Tensile Strength (Q235) | 370-500 MPa | GB/T 700 |

| Bearing Bar Depth | 20mm - 100mm | Customizable based on load |

| Bearing Bar Thickness | 3mm, 4mm, 5mm | Common industry sizes |

| Bearing Bar Spacing (Pitch) | 30mm, 40mm, 60mm | Optimized for load and opening size |

| Cross Bar Spacing (Pitch) | 50mm, 100mm | Enhances lateral stability |

| Surface Treatment | Hot-Dip Galvanized | ASTM A123 / ISO 1461 |

| Galvanized Coating Thickness | ≥ 85 µm (for ≥4.8mm material) | Ensures corrosion resistance |

| Open Area Percentage | 60% - 80% (approx.) | Light/air flow, debris passage |

| Panel Edge Finish | Banded (standard) | Enhanced rigidity and aesthetics |

| Surface Type Options | Plain, Serrated (anti-slip) | Safety considerations |

Versatile Applications: Where Q 235 Galvanized Press Locked Steel Grating Excels

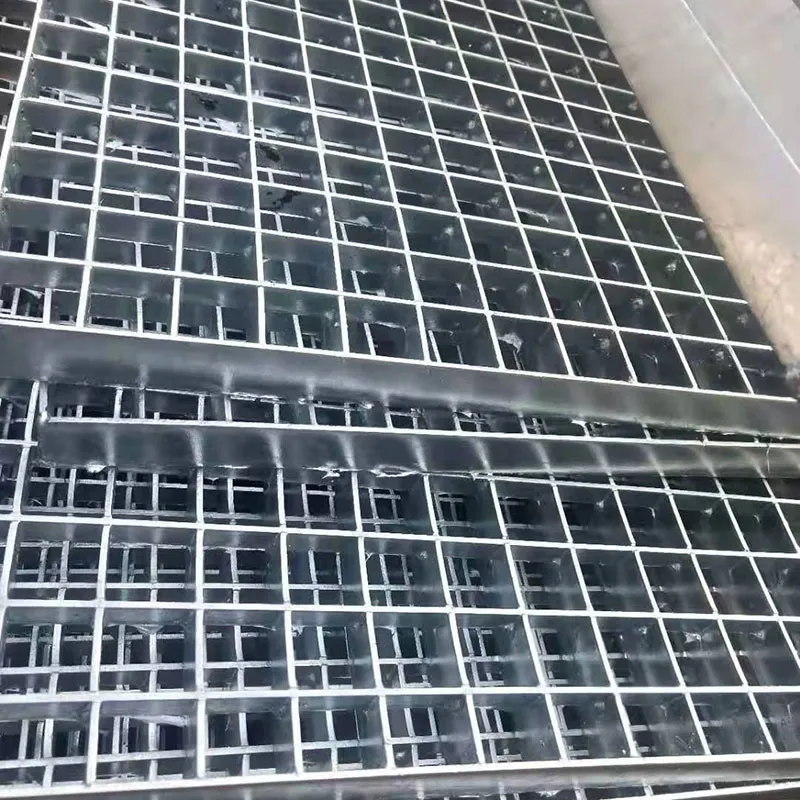

The robust design and exceptional properties of Q 235 Galvanized Press Locked Steel Grating For Walkway Platform make it an indispensable material across a vast array of industrial, commercial, and even architectural applications, providing safe, durable, and efficient access solutions. In heavy industrial settings such as petrochemical refineries, oil and gas platforms, power generation plants (including coal, nuclear, and renewable energy facilities), and mining operations, its primary role as a walkway platform is critical. Here, it facilitates safe passage for personnel across elevated structures, pipe racks, and machinery access points, enduring constant foot traffic, heavy equipment vibrations, and exposure to corrosive chemicals or extreme temperatures. The open mesh design is particularly advantageous in these environments, allowing for the rapid drainage of liquids, unimpeded airflow for ventilation, and the passage of light, which enhances visibility and safety below the platform. Furthermore, its use extends to industrial flooring within factories, workshops, and warehouses where heavy loads and vehicular traffic necessitate a floor that is not only strong but also resistant to impact and wear. For instance, in an automotive manufacturing plant, press-locked grating might be used for assembly line platforms, providing a non-slip surface that can withstand the weight of vehicles and machinery while allowing debris to fall through, simplifying cleaning processes. In water treatment plants and wastewater facilities, the corrosion resistance provided by hot-dip galvanization is paramount, protecting the steel from constant exposure to moisture and chemicals. Here, it is commonly utilized for tank covers, channel gratings, and pedestrian bridges, ensuring long-term structural integrity and minimal maintenance requirements in highly corrosive atmospheres. The metallurgical industry, encompassing steel mills and foundries, also heavily relies on this grating for furnace platforms, casting areas, and maintenance walkways, where its ability to withstand high temperatures and heavy loads is essential. Beyond these heavy-duty applications, Q 235 Galvanized Press Locked Steel Grating For Walkway Platform finds its place in more specialized contexts, such as stair treads, where its superior strength and non-slip surface ensure safety on vertical access routes. It is also frequently employed for trench covers and drainage grates in urban infrastructure projects, managing stormwater runoff efficiently while providing safe pedestrian or vehicular passage. In architectural applications, its clean lines and precise construction offer a modern aesthetic, making it suitable for sunscreens, facades, security screens, and decorative elements that require both structural integrity and visual appeal. The ability to customize dimensions, shapes, and cut-outs for pipes, columns, or irregular layouts further enhances its versatility, allowing it to be seamlessly integrated into complex designs. The global adoption of this grating solution underscores its proven reliability, cost-effectiveness over its long lifespan, and its critical contribution to operational safety and efficiency across diverse sectors, from hazardous industrial sites to public spaces requiring robust and durable surfaces.

Strategic Advantages: Why Q 235 Galvanized Press Locked Steel Grating Stands Out

The compelling array of technical and operational advantages offered by Q 235 Galvanized Press Locked Steel Grating For Walkway Platform positions it as a superior choice for a multitude of industrial and commercial applications, yielding significant long-term value for B2B stakeholders. One of its foremost strengths lies in its exceptional structural integrity and high strength-to-weight ratio. The innovative press-locking manufacturing method creates a rigid, unitary panel where bearing bars and cross bars are mechanically interlocked under immense pressure, eliminating the localized stresses and potential weakness associated with traditional welding processes. This results in a product with superior load-bearing capabilities, minimal deflection, and enhanced resistance to torsional forces, vibrations, and impact loads, making it ideal for high-traffic or dynamic environments where safety and reliability are paramount. Furthermore, the selection of Q235 steel, a widely available and cost-effective structural steel, combined with the efficient press-locking process, contributes to a highly economical solution without compromising performance. The subsequent hot-dip galvanization is perhaps its most significant advantage, imparting unparalleled corrosion resistance. The thick, metallurgically bonded zinc coating acts as both a barrier and a sacrificial anode, protecting the underlying steel from rust even if scratched, ensuring an extended service life often measured in decades, even in highly corrosive industrial or marine environments. This dramatically reduces maintenance costs and the frequency of replacements, translating into substantial operational savings over the lifespan of the infrastructure. The aesthetic appeal of press-locked grating is also a notable advantage. Its clean, precise lines, resulting from the flush top surfaces of the interlocked bars, provide a highly architectural appearance compared to welded alternatives. This makes it a preferred choice for applications where visual harmony is as important as functionality, such as building facades, pedestrian bridges, and public access areas. Beyond aesthetics and strength, safety is engineered into its core. The open mesh design facilitates excellent light penetration and airflow, reducing dark spots and improving ventilation in enclosed spaces. In outdoor settings, it allows snow, ice, and debris to fall through, preventing accumulation on the walking surface and enhancing safety. Optional serrated surfaces further augment slip resistance, providing a secure foothold even in wet, oily, or icy conditions, thereby reducing the risk of falls and improving workplace safety compliance. Installation is also streamlined due to the consistent panel dimensions and robust construction, allowing for quick and efficient assembly, often with standard clips and fasteners. This ease of installation translates into reduced labor costs and faster project completion times. Moreover, the inherent recyclability of steel, combined with the long lifespan of galvanized products, positions Q 235 Galvanized Press Locked Steel Grating For Walkway Platform as an environmentally responsible and sustainable choice, aligning with contemporary corporate environmental responsibility goals by minimizing material consumption and waste over time. These collective advantages—from superior strength and corrosion resistance to enhanced safety, aesthetic versatility, and long-term cost-effectiveness—make this specific type of grating a strategically sound and economically prudent investment for any modern industrial or commercial project.

Customization Capabilities and Bespoke Design Engineering for Q 235 Galvanized Press Locked Steel Grating

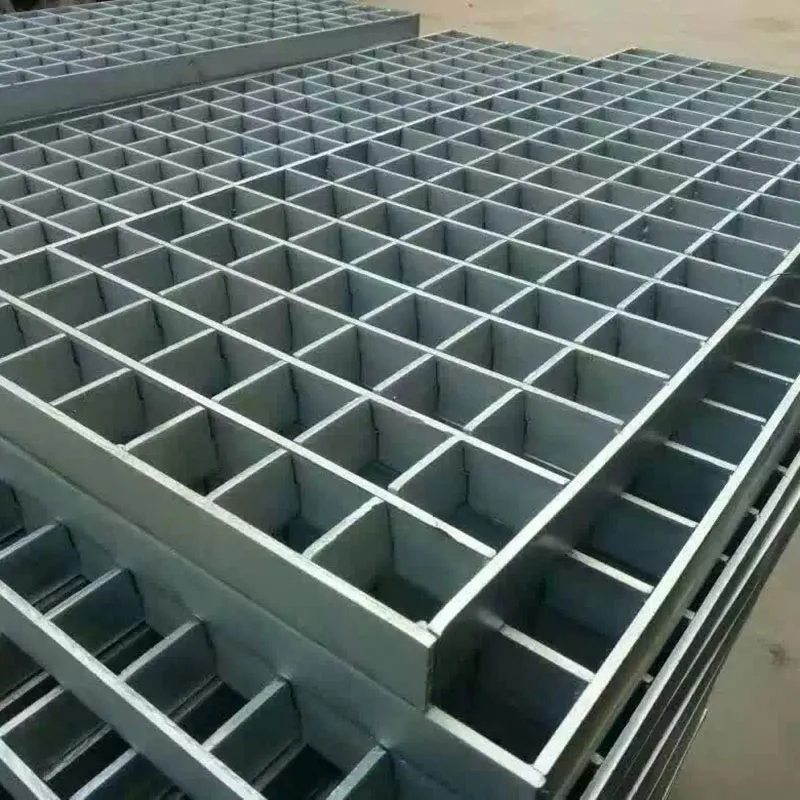

While standard panels of Q 235 Galvanized Press Locked Steel Grating For Walkway Platform cater to a broad range of industrial applications, the complexity and unique requirements of modern infrastructure projects frequently necessitate bespoke solutions. Reputable manufacturers excel in providing extensive customization capabilities, transforming raw materials into precisely engineered grating components that seamlessly integrate into highly specific architectural or operational designs. The process of customization begins with a detailed understanding of the client's project blueprints and functional requirements. This often involves collaborating with engineers, architects, and project managers to ascertain critical parameters such as exact dimensions, load-bearing requirements, desired open area, and environmental exposure. One of the primary areas for customization is the sizing of panels. While common widths and lengths are available, manufacturers can produce panels in virtually any specified dimension to minimize on-site cutting and waste, which reduces installation time and costs. Furthermore, the design flexibility extends to intricate cut-outs and penetrations. Industrial platforms frequently feature pipes, columns, equipment foundations, and irregular structural elements that require precise openings in the grating. Using advanced CNC laser cutting or plasma cutting technologies, manufacturers can create complex shapes and precise holes, ensuring a perfect fit around existing structures or for future installations, thereby maintaining the structural integrity and aesthetic continuity of the platform. Edge banding, while often standard, can also be customized. While common banding involves welding a flat bar around the perimeter for enhanced rigidity and a clean finish, specific applications may require alternative edge treatments or no banding at all, depending on whether the grating is to be recessed or flush with an adjacent surface. Another crucial aspect of customization involves selecting the appropriate bearing bar and cross bar configurations. Depending on the anticipated live loads, dead loads, and required span lengths, manufacturers can recommend or produce grating with varying bearing bar depths and thicknesses, as well as different bar spacings, to optimize for strength-to-weight ratio and cost-efficiency. For applications where enhanced slip resistance is critical, such as wet environments or areas prone to spills, customized serrated bearing bars can be specified. This feature involves notches or indentations on the top surface of the bearing bars, significantly increasing friction and providing a safer walking surface. Beyond these structural customizations, manufacturers can also address specific aesthetic preferences. While hot-dip galvanization provides a uniform metallic gray finish, some architectural projects might require additional powder coating or painting over the galvanized surface to match specific color schemes or to provide an extra layer of protection in extremely corrosive environments. The strength of a manufacturer’s customization offering is directly proportional to their engineering expertise, investment in advanced fabrication machinery, and their robust quality control procedures that ensure customized pieces maintain the same high performance standards as their off-the-shelf counterparts. Through these tailored solutions, Q 235 Galvanized Press Locked Steel Grating For Walkway Platform can be adapted to meet the most challenging and unique demands of any industrial or architectural project, ensuring optimal functionality, safety, and longevity.

Manufacturer Comparison: Key Criteria for Selecting Your Q 235 Galvanized Press Locked Steel Grating Supplier

The procurement of high-performance components like Q 235 Galvanized Press Locked Steel Grating For Walkway Platform necessitates a strategic approach to vendor selection, as the quality and reliability of the supplier directly impact project success, long-term operational costs, and safety. When evaluating potential manufacturers, several key criteria must be considered to ensure a sound investment. Firstly, look for a manufacturer with a proven track record and extensive industry experience, ideally with several years or decades of specialization in steel grating production. This longevity often signifies deep expertise, established processes, and a stable supply chain. Experience in handling diverse projects, from large-scale industrial complexes to intricate architectural installations, indicates versatility and a robust problem-solving capability. Secondly, examine their manufacturing capabilities and technology. A leading manufacturer will employ state-of-the-art machinery for precision cutting, press-locking, and hot-dip galvanization. Automated production lines, advanced robotics, and CNC integration reduce human error, ensure dimensional accuracy, and accelerate production turnaround times. Enquire about their galvanization process specifics, including adherence to global standards such as ASTM A123 or ISO 1461, and their ability to consistently achieve specified coating thicknesses for optimal corrosion resistance. Thirdly, quality control and certifications are non-negotiable. A reputable supplier will hold international certifications like ISO 9001 for quality management systems, demonstrating a commitment to continuous improvement and consistent product quality. They should also provide comprehensive material test reports (MTRs) for the Q235 steel, galvanization thickness certificates, and perform in-house load testing or engage third-party verification for their grating products. Compliance with industry standards like ANSI/NAAMM MBG (Metal Bar Grating Manual) is also a strong indicator of quality. Fourthly, evaluate their engineering and design support. The ability to offer bespoke solutions, including custom sizes, complex cut-outs, and specific load calculations, is vital for projects with unique requirements. A manufacturer with an experienced engineering team can assist in optimizing grating designs for specific applications, recommending the most suitable specifications for bearing bar size, spacing, and surface types (e.g., plain vs. serrated) to meet performance and safety criteria. Fifthly, assess their production capacity and lead times. For large-scale projects, a manufacturer’s ability to meet volume demands and adhere to agreed-upon delivery schedules is critical to avoid project delays. Request information on their typical lead times for standard and custom orders, and their logistical capabilities for domestic and international shipping. Finally, consider their customer service and after-sales support. This includes responsiveness to inquiries, clarity of communication, warranty provisions, and post-installation support. A manufacturer that offers robust customer support, including technical assistance, installation guidelines, and comprehensive warranty coverage, demonstrates a commitment to client satisfaction and stands by the quality of their Q 235 Galvanized Press Locked Steel Grating For Walkway Platform. By meticulously evaluating these criteria, B2B buyers can confidently select a manufacturer that not only supplies high-quality grating but also acts as a reliable partner in ensuring the long-term success and safety of their infrastructure projects.

Real-World Impact: Illustrative Case Studies and Project Successes with Q 235 Galvanized Press Locked Steel Grating

The practical effectiveness and superior performance of Q 235 Galvanized Press Locked Steel Grating For Walkway Platform are best demonstrated through its successful deployment in various demanding real-world scenarios, showcasing its versatility and problem-solving capabilities across diverse industries. Consider a large-scale power plant expansion project in a coastal region, where the existing infrastructure suffered from significant corrosion due to saline atmospheric conditions. The challenge was to replace kilometers of deteriorating access platforms and stairways with a material that could withstand extreme environmental exposure while ensuring minimal downtime during installation. The project team specified Q235 Galvanized Press Locked Steel Grating due to its exceptional corrosion resistance afforded by the thick hot-dip galvanized coating and its high strength-to-weight ratio, which simplified structural support requirements. Custom-fabricated panels with serrated surfaces were crucial for ensuring slip resistance on platforms regularly exposed to moisture and sea spray. The precision of the press-locked construction allowed for rapid, efficient installation, with pre-cut panels fitting seamlessly around existing pipes and equipment, leading to a 30% reduction in installation time compared to traditional welded grating, and the new platforms are projected to have a lifespan exceeding 50 years, significantly reducing future maintenance costs. In another instance, a major petrochemical refinery undertaking an upgrade of its crude distillation unit required safe, robust, and fire-resistant elevated walkways for operational and maintenance personnel. Given the potential for oil spills and chemical exposure, the choice of flooring was critical. The refinery opted for Q 235 Galvanized Press Locked Steel Grating For Walkway Platform due to its inherent fire resistance (steel is non-combustible), excellent drainage capabilities preventing accumulation of flammable liquids, and the long-term protection offered by galvanization against a range of corrosive chemicals. The specific design included a tighter bearing bar spacing to ensure worker safety against falling objects through the grating, while still maintaining optimal ventilation. The project successfully enhanced worker safety, minimized operational hazards, and provided a durable access system that can withstand the rigorous demands of refinery operations. Furthermore, a new urban pedestrian bridge project aimed to combine functionality with modern aesthetics. The design called for a lightweight yet robust decking material that could provide secure footing and allow light to filter through to the area below, creating an open and inviting public space. Architects selected Q235 Galvanized Press Locked Steel Grating for its clean lines, superior strength, and ability to be custom-fabricated into curved sections and various dimensions. The inherent beauty of the press-locked pattern, combined with the subtle sheen of the galvanized finish, contributed significantly to the bridge's contemporary visual appeal, while its non-slip surface ensured public safety in all weather conditions. These examples underscore how Q 235 Galvanized Press Locked Steel Grating For Walkway Platform consistently delivers on its promises of durability, safety, and efficiency, providing tailored solutions to complex industrial and architectural challenges, proving itself as a strategic asset for long-term infrastructure development.

Ensuring Trust: Quality Assurance, Certifications, and Unwavering Customer Support

The foundation of trust in the B2B sector, especially concerning critical infrastructure components like Q 235 Galvanized Press Locked Steel Grating For Walkway Platform, is built upon rigorous quality assurance protocols, verifiable certifications, and comprehensive customer support. Leading manufacturers prioritize a holistic approach to quality, beginning with the meticulous sourcing of raw materials. Each batch of Q235 steel undergoes stringent chemical composition analysis and mechanical property testing upon arrival to ensure it meets the stipulated GB/T 700 standards. Throughout the manufacturing process, from cutting and notching to the critical press-locking operation, in-process inspections are routinely conducted to verify dimensional accuracy, alignment, and the integrity of the interlocked joints. This proactive quality control minimizes defects and ensures consistent product quality. The hot-dip galvanization stage is subjected to equally rigorous testing, with regular checks on zinc bath composition and temperature, and post-galvanization measurements of coating thickness using magnetic or eddy current gauges, in strict adherence to international standards like ASTM A123/A123M or ISO 1461. Adherence to these standards is not merely a formality but a testament to a manufacturer’s commitment to providing a product with certified corrosion resistance and durability. Furthermore, reputable suppliers perform comprehensive final inspections, including visual checks for surface finish, absence of sharp edges, and overall panel integrity, along with load-bearing tests to validate the grating's structural performance against design specifications and relevant industry codes (e.g., ANSI/NAAMM MBG). Certifications play a pivotal role in establishing authority and trustworthiness. ISO 9001 certification for Quality Management Systems indicates that the manufacturer has established a robust framework for consistent quality production, customer satisfaction, and continuous improvement. For products distributed internationally, CE marking (Conformité Européenne) signifies compliance with European Union safety, health, and environmental protection directives. Beyond product certifications, long-standing industry presence and reputable partnerships (e.g., with major engineering firms or construction companies) serve as strong indicators of reliability. A comprehensive warranty, typically ranging from 5 to 10 years or more depending on environmental conditions, underscores the manufacturer's confidence in their product's longevity and performance. Delivery and logistics are also key components of trustworthiness. Efficient supply chain management, transparent communication regarding lead times, secure packaging to prevent transit damage, and reliable international shipping capabilities ensure that products arrive on schedule and in pristine condition, minimizing project delays. Finally, exceptional customer support encompasses not only pre-sales technical consultation and design assistance but also post-sales support, including detailed installation guides, troubleshooting assistance, and responsiveness to any client concerns. A dedicated FAQ section on a manufacturer’s website or in their documentation can preempt common questions regarding installation, maintenance, and product specifications, further enhancing the user experience and building confidence in the supplier’s expertise and reliability. By emphasizing these pillars—uncompromising quality assurance, recognized certifications, and a steadfast commitment to customer support—manufacturers of Q 235 Galvanized Press Locked Steel Grating For Walkway Platform cultivate enduring trust and position themselves as reliable partners in complex industrial ventures.

Frequently Asked Questions (FAQs)

- What is the typical lifespan of Q 235 Galvanized Press Locked Steel Grating? The lifespan is heavily dependent on the environment, but with a proper hot-dip galvanized coating (meeting ASTM A123 or ISO 1461 standards), it can last 50 years or more in rural areas, 20-25 years in industrial/urban environments, and 10-15 years in severe marine or chemical exposures.

- Can this grating be used outdoors in harsh weather conditions? Absolutely. The hot-dip galvanization provides excellent resistance to rain, snow, ice, and UV radiation. Its open mesh design prevents water and snow accumulation, making it ideal for outdoor walkways, platforms, and stair treads in all climates.

- Is slip resistance an issue, especially in wet conditions? Standard plain surface grating offers good friction, but for enhanced safety in wet, oily, or icy environments, serrated bearing bars are available as an option. These serrations significantly increase slip resistance and comply with relevant safety standards.

- How do I specify the correct grating for my load requirements? You need to provide the anticipated live load (people, equipment), dead load (weight of the grating itself, fixed equipment), and the span length (distance between supports). Manufacturers' engineering teams can then calculate the appropriate bearing bar depth, thickness, and spacing to meet your specific load-bearing requirements and safety factors.

- What are the maintenance requirements for Q 235 Galvanized Press Locked Steel Grating? One of its key advantages is minimal maintenance. The hot-dip galvanized coating protects against corrosion, eliminating the need for painting or frequent re-coating. Routine cleaning to remove debris and periodic visual inspections for damage are typically sufficient.

The Future Landscape: Industry Trends and Sustainable Practices in Steel Grating Manufacturing

The industry for industrial steel grating, particularly for products like Q 235 Galvanized Press Locked Steel Grating For Walkway Platform, is continually evolving, driven by advancements in materials science, manufacturing technology, and an increasing global emphasis on sustainability and smart infrastructure. One prominent trend is the growing demand for higher performance characteristics, often translating into lighter weight solutions that maintain or exceed current load-bearing capacities. This is being achieved through optimized design algorithms and potentially through the incorporation of higher strength steel grades in specific applications, though Q235 remains a cost-effective and highly versatile standard. Automation and digitalization are profoundly transforming the manufacturing process. Advanced robotic welding, automated cutting, and integrated CAD/CAM systems are enhancing precision, reducing production times, and minimizing waste. Digital twins and Building Information Modeling (BIM) are becoming more prevalent, allowing for seamless integration of grating designs into larger project models, facilitating clash detection, and improving overall project efficiency from design to installation. This trend towards intelligent manufacturing not only boosts productivity but also ensures a higher degree of customization and accuracy for complex projects. Furthermore, there's an increasing focus on the environmental footprint of industrial components. Manufacturers are investing in more energy-efficient production processes, optimizing material usage to reduce scrap, and exploring innovative recycling initiatives for both steel and zinc. The inherent recyclability of steel makes Q 235 Galvanized Press Locked Steel Grating For Walkway Platform a strong contender in the circular economy, with minimal environmental impact at the end of its exceptionally long service life. Hot-dip galvanization itself is a sustainable process, as zinc is a natural element that is infinitely recyclable, and the longevity it imparts significantly reduces the carbon footprint associated with repeated replacements. Safety remains a paramount concern, driving innovations in anti-slip surfaces, ergonomic designs for access points, and the development of intelligent monitoring systems that could potentially alert maintenance teams to areas requiring inspection or repair. The integration of sensors into grating systems to monitor load, vibration, or even environmental conditions is a nascent but promising area of research, potentially leading to predictive maintenance capabilities. The trend towards modular construction is also influencing grating design, with manufacturers developing more standardized, yet adaptable, components that can be quickly assembled on-site, reducing construction time and costs. This modularity also simplifies future expansions or modifications of industrial facilities. Finally, global supply chain resilience is a renewed focus, with manufacturers diversifying sourcing and optimizing logistics to mitigate risks associated with geopolitical events or natural disasters. The future of Q 235 Galvanized Press Locked Steel Grating For Walkway Platform lies in its continuous adaptation to these evolving demands, ensuring it remains a cornerstone of safe, efficient, and sustainable industrial infrastructure worldwide.

Cited References & Further Reading

- American Galvanizers Association (AGA). "Hot-Dip Galvanizing Process." Retrieved from galvanizeit.org.

- ASTM International. "ASTM A123/A123M-17: Standard Specification for Zinc Coatings on Iron and Steel Products." Retrieved from astm.org.

- National Association of Architectural Metal Manufacturers (NAAMM). "ANSI/NAAMM MBG 531-09: Metal Bar Grating Manual." Retrieved from naamm.org.

This is the first article

Latest News

-

Competitive Mesh Reinforcement Price - Concrete Mesh for Sale

NewsAug.09,2025

-

CBT 65 Concertina Razor Wire Fencing for Sale - High Security

NewsAug.08,2025

-

Bulk Deco Mesh Wholesale | Cheap Decorative Mesh Rolls

NewsAug.07,2025

-

Durable Wire Mesh Conveyor Belts | Custom Solutions

NewsAug.06,2025

-

Premium Dry Wall Corner Bead - Durable & Easy Install

NewsAug.05,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA