Jul . 29, 2025 18:00 Back to list

Competitive Galvanized Grating Price for Durable Flooring Solutions

As industrial infrastructure advances, the demand for high-performance galvanized steel grating continues to surge, especially in sectors prioritizing durability and anti-corrosive properties. This in-depth guide covers everything you need to know about galvanized grating price, technical specifications, manufacturing technology, and real-world application scenarios.

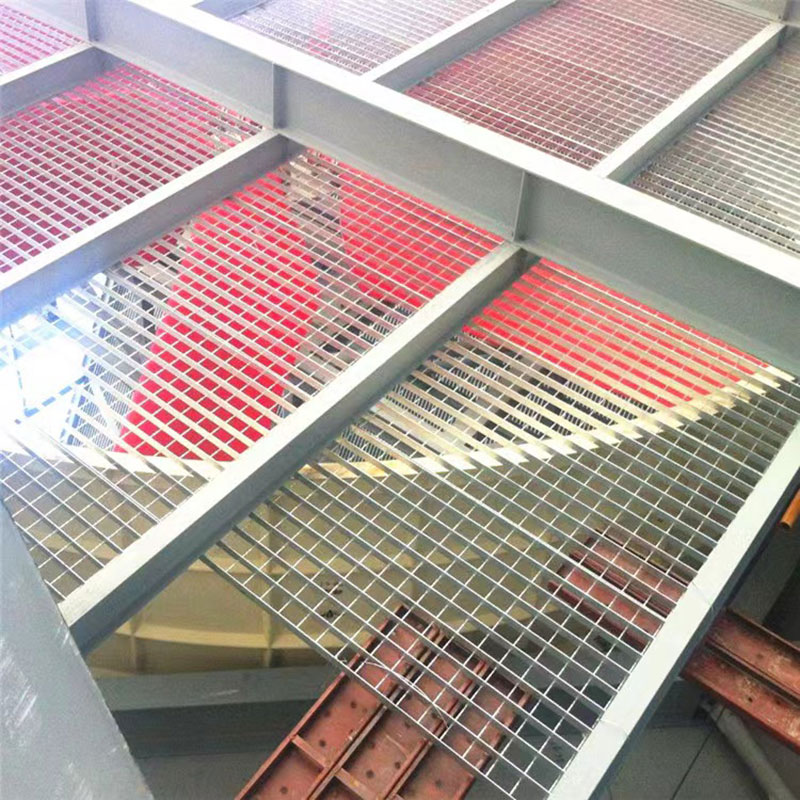

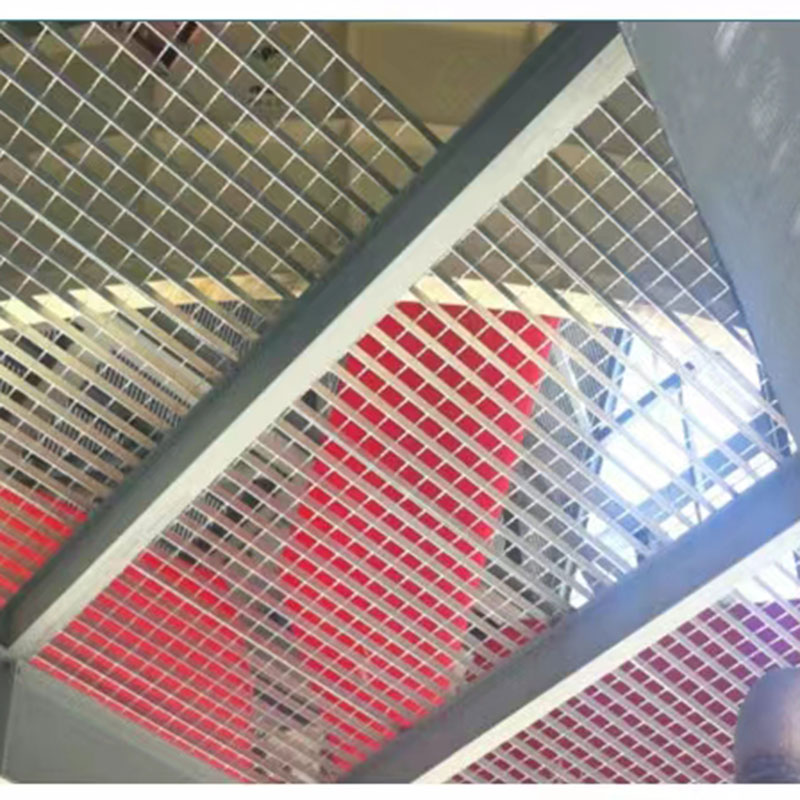

Featured Product: Hot Dipped Galvanized Welded Metal Grid Steel Grating Ceiling

According to Statista, the worldwide grating market is anticipated to exceed $2000 Million USD by 2027, with hot-dipped galvanized grating contributing the lion's share due to its longevity, structural integrity, and cost efficiency. Industry leaders consistently select galvanized steel grate for projects exposed to corrosive environments, including petrochemical plants, wastewater facilities, power plants, and transport infrastructure.

| Region | Average Galvanized Grating Price | Main Application | Lead Time |

|---|---|---|---|

| North America | $34 – $55 | Oil, Gas, Construction | 7-21 days |

| Europe | $42 – $68 | Petrochemical, Energy | 15-28 days |

| Middle East | $31 – $57 | Desalination, Waterworks | 10-18 days |

| Asia Pacific | $26 – $48 | Manufacturing, Civil Infra | 5-15 days |

- Raw Material Selection

— Select premium low-carbon steel (Q235/Q195 or SS400). Compliant with EN 10025. - Fabrication

— Bar cutting, cross bar insertion, CNC resistance welding for precise mesh. - Dimensioning/Finishing

— Edge cutting, trimming, and deburring for safety. - Hot-Dip Galvanizing (Zinc ≥610g/m²)

— Immersed in 98% zinc bath per ISO 1461 to ensure anti-rust coating thickness. - Inspection & Packaging

— Salt-spray testing, adherence to ANSI/NAAMM MBG531, marking, and shipment.

| Parameter | Standard Value | Reference (Standard/Typical Value) |

|---|---|---|

| Material | Low-carbon Steel (Q235/Q195, SS400) | EN 10025, ASTM A36 |

| Surface Coating | Hot-Dip Galvanized (Zn ≥ 610g/㎡) | ISO 1461, ASTM A123 |

| Load Bar Size | 25×3mm / 30×3mm / 30×5mm (Customizable) | Standard: 25-50mm x 3-5mm |

| Mesh Pitch | 30×100mm / 40×100mm / 50×100mm | Welded at every intersection |

| Bearing Capacity | ≥ 4000kg/m² | Tested by ISO 14122/EN 1090 |

| Galvanizing Thickness | > 85μm | ISO 1461:2018 |

| Slip Resistance | Class R10 / A ≥25mm | DIN 51130 |

| Fire Performance | Noncombustible (A1) | EN 13501-1 |

| Expected Service Life | ~35+ years | In 6-12pH, outdoors, per ISO 9224 |

| Type | Production Process | Surface Treatment | Cost (USD/㎡) | Service Life | Load Bearing | Common Use |

|---|---|---|---|---|---|---|

| Hot Dipped Galvanized Grating | Welded/CNC | Hot Dip Zinc ≥610g/㎡ | $26-$55 | 35+ yrs | High | Industry Flooring, Walkway, Catwalk |

| Powder-Coated Steel Grating | Welded/Pressed | Powder-Epoxy | $28-$60 | 10-18 yrs | Medium | Interior Grates, Trays |

| Stainless Steel Grating | Pressed/Cast | SS304/SS316 | $95-$150 | 50+ yrs | Very High | Food, Marine, Chemical |

| FRP Grating | Molded/Extruded | Fiberglass Resin | $38-$82 | 18-28 yrs | Medium | Chemical, Water |

Challenge: Extreme exposure to corrosive gases.

Solution: High-zinc-layer grating galvanized by ISO 1461, acting as walkway, minimizing downtime.

Challenge: Permanent wet, alkaline splash.

Solution: Serrated galvanized grating for anti-slip cover in tanks.

Challenge: Heavy dynamic load and mechanical abrasion.

Solution: Welded galvanized steel grating, bar thickness ≥5mm for floors, truck entries.

Challenge: Demanding visual and air flow requirements.

Solution: Custom hot dipped galvanized welded metal grid ceiling for Louvre Abu Dhabi.

- Full range of bar sizes: 20×3mm up to 65×5mm

- Mesh pitch from 20×20mm up to 80×100mm

- Optional: serrated or smooth, cut shapes (curved, circular), removable or secured

- Special coatings: extra-thick galvanizing, powder/epoxy overcoat

- Welding method: traditional resistance/cast or robotic CNC

- Marking: Custom logo, quick shipping with batch traceability

Warranty: 5-Year Replacement Guarantee (Corrosion Rate Verified ≤2.5μm/a by ISO 9226 Salt Spray).

— Plant Manager, Thai Chemical Group (2022)

— Construction foreman, Turkish EPC Company (2023)

- Consistently competitive galvanized grating price compared to both European and North American suppliers.

- Strict adherence to ISO, ANSI, and EN fabrication and test standards.

- Team with 15+ years export experience, serving Fortune 500 EPCs worldwide.

- Genuine manufacturer — not a trading middle agent — with full traceability.

- After-sales technical support, layout design service, and on-site installation guidance available.

- All certifications, mechanical and corrosion test reports available for download.

- Download Full Technical Catalog & Data Sheet

- Email: sales@chengsenmesh.com | WhatsApp/WeChat available on request

- “Global Steel Grating Market 2023–2030 Overview.” Statista

- “Hot-Dip Galvanized (HDG) Steel Grating Standards.” ISO 1461:2018

- “Steel Grating Selection & Installation.” NAAMM MBG-531. NAAMM

- Science Direct – Galvanized Steel Structures: Durability & Corrosion Trends, 2018

Latest News

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

-

Welded Wire Fencing Diamond Hole Anti Climb Razor Concertina Mesh Fence

NewsJul.29,2025

-

Galvanized Flat Security Fencing Razor Blade Barbed Wire Mesh Fence Coil

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA