Feb . 18, 2025 08:26 Back to list

wire mesh dimensions

For newcomers and seasoned professionals alike, the standards and tolerance levels required in wire mesh dimensions can be a complex topic. The American Society for Testing and Materials (ASTM) provides guidelines that are widely adopted to ensure quality and consistency. Following such recognized standards is not merely a matter of compliance but embodies a commitment to reliability and trustworthiness, fostering customer confidence. One pivotal aspect often overlooked is the integration of digital technology in the design and measurement of wire mesh dimensions. Advanced CAD software and digital calipers ensure precision cutting and manufacturing, reducing human error. From my perspective, businesses that leverage such technologies experience a notable competitive advantage, achieving higher precision and production efficiency. Having consulted for numerous construction projects around the globe, I can assert that the successful application of wire mesh dimensions involves scrutinizing every detail, from initial design through to final installation. For example, in earthquake-prone regions, wire mesh is often used to reinforce concrete structures. Here, precise application of dimensions ensures enhanced structural integrity and safety. To stay ahead in the competitive market, continuous learning and adaptation are key. Engaging with updated resources and industry conferences can provide invaluable insights into emerging trends and innovations in wire mesh technology. Personal experience, continued professional development, and engagement with a network of industry peers collectively inform a comprehensive expertise that enhances credibility and authority. For any stakeholder in industries leveraging wire mesh, understanding and correctly applying wire mesh dimensions are imperative for ensuring the longevity, safety, and efficiency of their projects. By prioritizing dimension accuracy and compliance, while embracing technological advancements, professionals can deliver projects that not only meet but exceed expectations, establishing themselves as trusted and reliable experts in their field.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

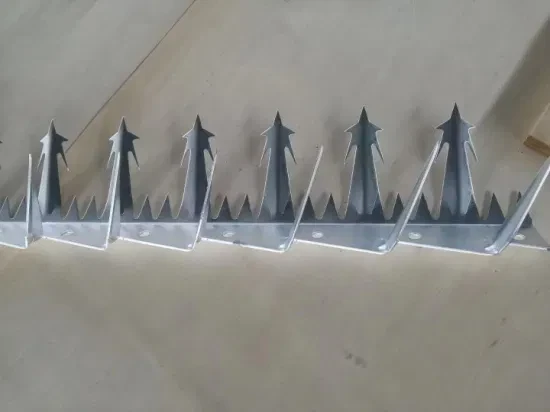

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA