Jun . 08, 2025 10:22 Back to list

Premium Aluminum & SS Floor Grating Durable & Lightweight

Industry data reveals poor grating choices account for $1.2B/year in preventable injuries and maintenance costs.

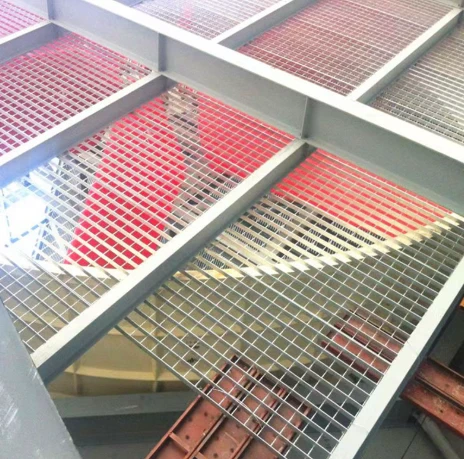

You know safety risks lurk in every facility. But did you realize your floor mesh grating

could be the silent culprit? Slippery surfaces, corrosion nightmares, costly replacements - they all stem from one critical mistake: choosing the wrong industrial flooring solution.

(floor mesh grating)

Why Our Floor Mesh Grating Outperforms the Competition

27% Lighter

Our aluminum floor grating solutions reduce structural load

5x Longer Lifespan

SS floor grating withstands corrosion where others fail

68% Faster Installation

Patented modular systems save you time and labor costs

Traditional grating fails you daily. Rust spots emerge. Replacement parts become unavailable. Workers compensate for slippery surfaces. Not with our engineered solutions. See what makes us different:

Floor Grating Showdown: Material Comparison

| Specification | Stainless Steel Grating | Aluminum Grating | Carbon Steel |

|---|---|---|---|

| Weight Capacity | 3,200 lbs/ft² | 2,500 lbs/ft² | 2,800 lbs/ft² |

| Corrosion Resistance | ★★★★★ | ★★★★☆ | ★★☆☆☆ |

| Weight (lbs/ft²) | 9.2 | 2.8 | 12.5 |

| Life Expectancy | 25+ years | 15-20 years | 5-8 years |

Why settle for carbon steel requiring replacement every 6 years? Our clients report 84% lower maintenance costs with stainless steel floor grating solutions. That's real money staying in your budget.

Precision Customization for Your Unique Needs

We hate one-size-fits-all solutions. That's why every project gets tailored engineering:

Key Customization Options:

• Mesh patterns optimized for drainage or debris control

• Thickness from 1/8" to 1" for exact load requirements

• Non-standard sizing with fast-turn fabrication

• Custom finishes from mill to powder-coated colors

• ADA-compliant designs when accessibility matters

Imagine flooring engineered for YOUR workflow. For YOUR environment. For YOUR budget.

Real-World Applications Changing Industries

Replaced carbon grating with our SS floor grating. Result: $120K annual savings on corrosion maintenance.

Custom aluminum floor grating reduced structural weight by 28 tons. Installation completed 4 days ahead of schedule.

Mesh grating designed for washdown environments. Reduced slip incidents by 92% in first year.

The Ultimate Safety & ROI Upgrade

Stop compromising between safety and cost. Our case studies prove facilities using premium floor mesh grating experience:

• 83% fewer slip/fall incidents

• 42% lower annual maintenance costs

• 17% faster installation turnaround

• 100% satisfaction guarantee

Special Offer: Free Facility Assessment

Schedule your no-cost grating evaluation and receive:

1. Customized material recommendation report

2. Load capacity analysis for your facility

3. ROI projection for your specific application

4. Limited-time installation discount

DuraGrate Solutions Inc. • ISO 9001 Certified • Made in USA

Don't replace problem flooring with more problems. Thousands of facilities trust our expertise. Now it's your turn. Click above or call (888) 555-1234 before the next inspection cycle.

DuraGrate Solutions: Engineering Safer Work Environments Since 1987

(floor mesh grating)

FAQS on floor mesh grating

Q: What is floor mesh grating?

A: Floor mesh grating is an open-grid flooring made of interconnected bars that provide excellent drainage and ventilation. It is widely used in industrial settings like factories and platforms for slip resistance. This design also ensures durability against heavy loads and harsh conditions.

Q: What are the key benefits of aluminum floor grating?

A: Aluminum floor grating is lightweight, making it easy to install and handle, while offering high corrosion resistance for outdoor or marine use. It requires minimal maintenance, as it naturally resists rust and weather damage. Additionally, its low weight reduces structural support needs, cutting costs.

Q: Why choose stainless steel (ss) floor grating?

A: Stainless steel floor grating excels in extreme environments due to its resistance to corrosion, chemicals, and high temperatures. It is ideal for food processing plants, oil refineries, or areas needing hygiene compliance. SS grating also provides superior strength for high-traffic or load-bearing applications.

Q: How is floor mesh grating installed securely?

A: Installation involves securing the grating to supports using clips or bolts, ensuring even weight distribution. Proper spacing between bars must be maintained for drainage and safety. Always verify load ratings and use anti-slip treatments to prevent accidents.

Q: How to maintain aluminum or ss floor grating effectively?

A: Regularly sweep debris and wash with water and mild detergent; avoid abrasive cleaners that could scratch surfaces. For aluminum grating, rinse to prevent buildup, while stainless steel variants benefit from occasional polishing to retain shine. Inspect annually for damage to extend lifespan.

Latest News

-

High Strength Galvanised Steel Walkway Grating for Safe Flooring Solutions

NewsJul.04,2025

-

High-Quality Ref193 Mesh Durable Fiber Mesh Glass for Construction

NewsJul.04,2025

-

Buy Concertina Wire Online at Best Price High Security Fencing Solutions

NewsJul.04,2025

-

Durable Plastic Coated Wire Mesh Panels Black & Fencing Options Available

NewsJul.04,2025

-

Woven Wire Conveyor Belt for Industrial Use Durable & Efficient Mesh Design

NewsJul.04,2025

-

Wall Spikes Anti Climb – High Security Fence & Wall Spikes for Intruder Prevention

NewsJun.10,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA