Jan . 14, 2025 10:50 Back to list

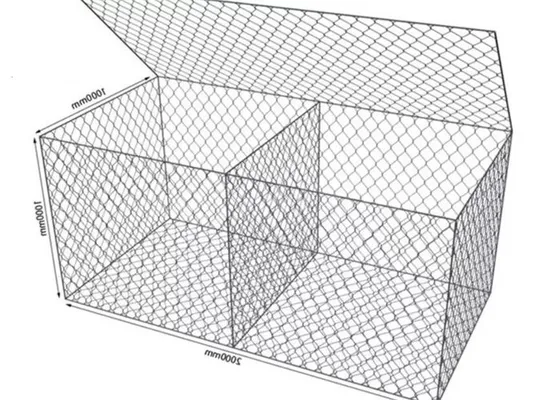

galvanized grating

Authoritativeness in the field of expanded metal gratings is bolstered by stringent quality standards and certifications. Many manufacturers adhere to ISO certifications, guaranteeing that their products meet international criteria for quality and safety. These standards ensure that the grating's mechanical properties are consistent, providing peace of mind to engineers and architects who specify its use in critical applications. The trust in these products is further cemented by testimonials and case studies published by reputable firms who have successfully integrated this grating in their projects. Trustworthiness is perhaps the most critical component when discussing 3.14 expanded metal grating. Engineers and architects rely heavily on suppliers who provide comprehensive technical support and product information. Transparent communication about load ratings, installation procedures, and performance metrics fosters confidence. Moreover, customer support teams that offer prompt assistance reinforce the trust relationship, ensuring any issues that arise can be swiftly addressed. The versatility of 3.14 expanded metal grating is truly unparalleled. It accommodates various coatings and finishes, enhancing its applicability in diverse environments. For example, galvanizing offers exceptional corrosion resistance for outdoor applications, while powder coatings allow for aesthetic customization without sacrificing durability. Such versatility not only widens its application but also allows for creative architectural expressions in projects aiming for a modern aesthetic. In conclusion, 3.14 expanded metal grating stands out as an exemplary product, marrying functionality with reliability. Its proven track record in multiple industries, combined with its adaptability to specialized industrial needs, makes it an invaluable component in modern construction and design. As more professionals recognize its advantages, the demand for this innovative material is expected to grow, cementing its status as a mainstay in the world of versatile, high-performance materials.

Latest News

-

Brick Mesh Wall Solutions | Enhanced by GPT-4 Turbo Design

NewsAug.01,2025

-

Premium Anti-Climb Fence Spikes for Sale

NewsAug.01,2025

-

Premium Peach Post Fence | Durable & Stylish Security

NewsJul.31,2025

-

Best Galvanized Grating Price - Durable Galvanized Steel Grating Solutions

NewsJul.30,2025

-

0.5-4.0mm Wire 2×2 4×4 8×8 Hot Dipped Galvanized Welded Mesh Roll

NewsJul.30,2025

-

Metal Fence Pickets for Sale – Durable Galvanized & Steel Options

NewsJul.29,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA