আগস্ট . 13, 2025 04:40 Back to list

I-Shape Steel Grating: Plain & Serrated, High Strength

Understanding I-Shape Plain and Serrated Steel Grating: An Industry Overview

In the demanding landscape of industrial infrastructure, the choice of flooring, platforms, and trench covers is paramount for safety, durability, and operational efficiency. Among the myriad options, I Shape Plain And Serrated Steel Grating stands out as a superior solution. This specialized grating, characterized by its unique "I" beam bearing bar profile, offers an exceptional strength-to-weight ratio compared to traditional flat bar gratings, leading to reduced material costs and easier installation. Its versatile design allows for both plain and serrated surfaces, catering to diverse application needs ranging from pedestrian walkways to heavy-duty industrial platforms where slip resistance is critical. This section delves into the evolving market trends, the fundamental advantages of I-shape grating, and its strategic importance in modern industrial applications, reflecting a global shift towards more efficient and safer industrial components.

The global demand for industrial grating is experiencing steady growth, driven by expansion in sectors such as petrochemicals, power generation, wastewater treatment, and offshore oil and gas. Companies are increasingly prioritizing solutions that offer enhanced safety features, extended service life, and lower maintenance costs. The inherent structural efficiency of I Shape Plain And Serrated Steel Grating directly addresses these requirements. Its design allows for greater load-bearing capacity with less material, translating into more economical long-span installations. Furthermore, the option of a serrated surface significantly improves traction in wet, oily, or icy conditions, mitigating risks of slips and falls—a critical factor in environments adhering to stringent safety regulations like those set by OSHA. This adaptability positions I-shape grating as a cornerstone in industrial design, reflecting a broader industry trend towards optimized, safer, and more sustainable infrastructure components.

The Advanced Manufacturing Process of I Shape Plain And Serrated Steel Grating

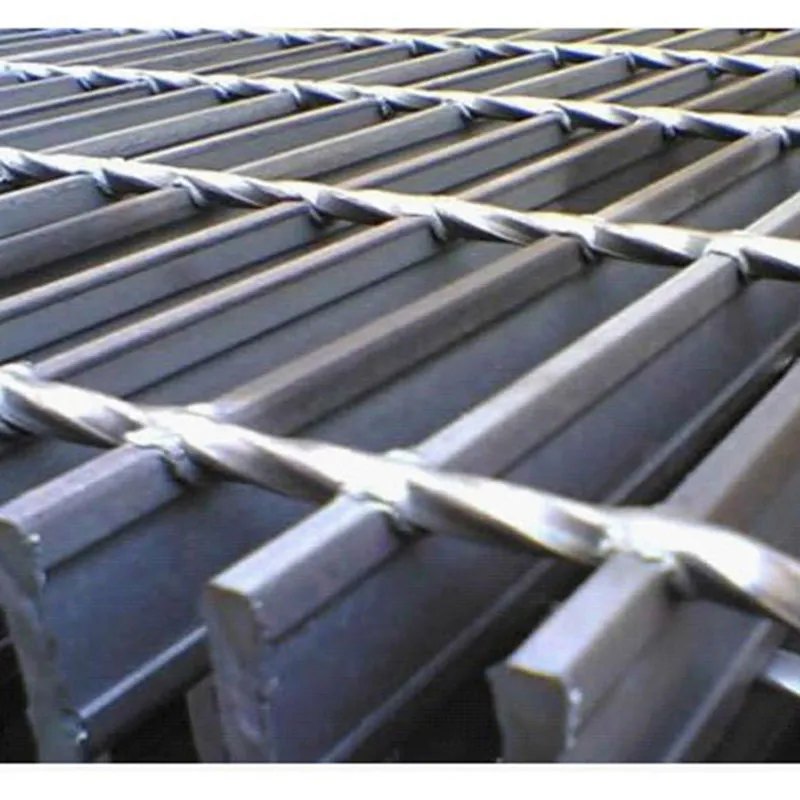

The production of I Shape Plain And Serrated Steel Grating is a sophisticated multi-stage process, meticulously engineered to ensure superior quality and performance. It begins with the selection of high-grade raw materials, typically low carbon steel (e.g., Q235, A36), stainless steel (e.g., SS304, SS316), or aluminum alloys, chosen based on the intended application's demands for strength, corrosion resistance, and environmental compatibility. The core of the grating, the "I" section bearing bar, is typically formed through hot rolling or cold drawing processes, achieving the characteristic I-profile that maximizes bending stiffness while minimizing weight. For serrated variants, a specialized rolling process integrates the anti-slip teeth onto the top surface of the bearing bars, ensuring enhanced friction and safety.

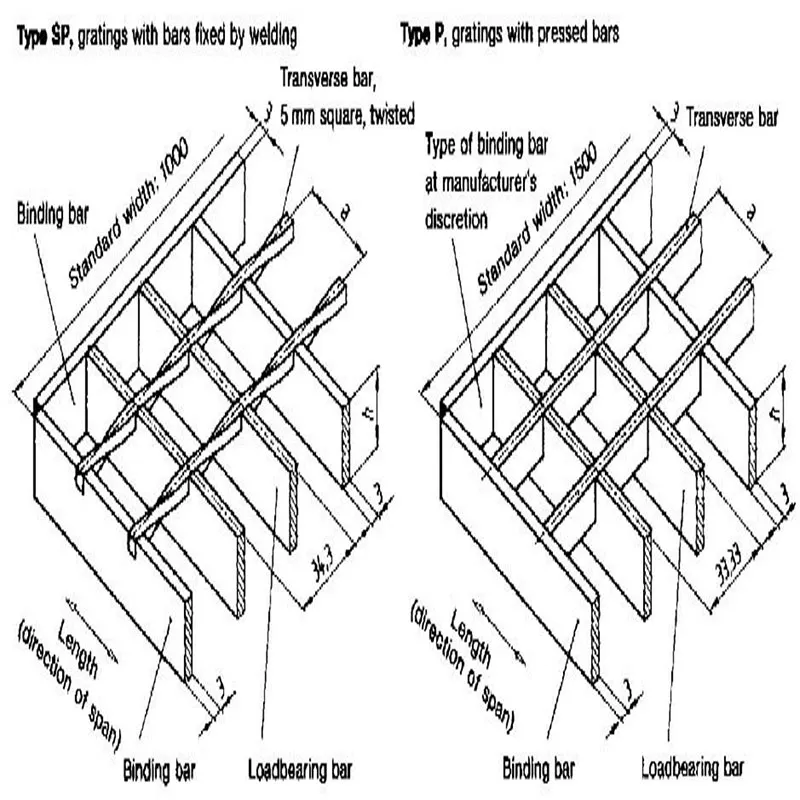

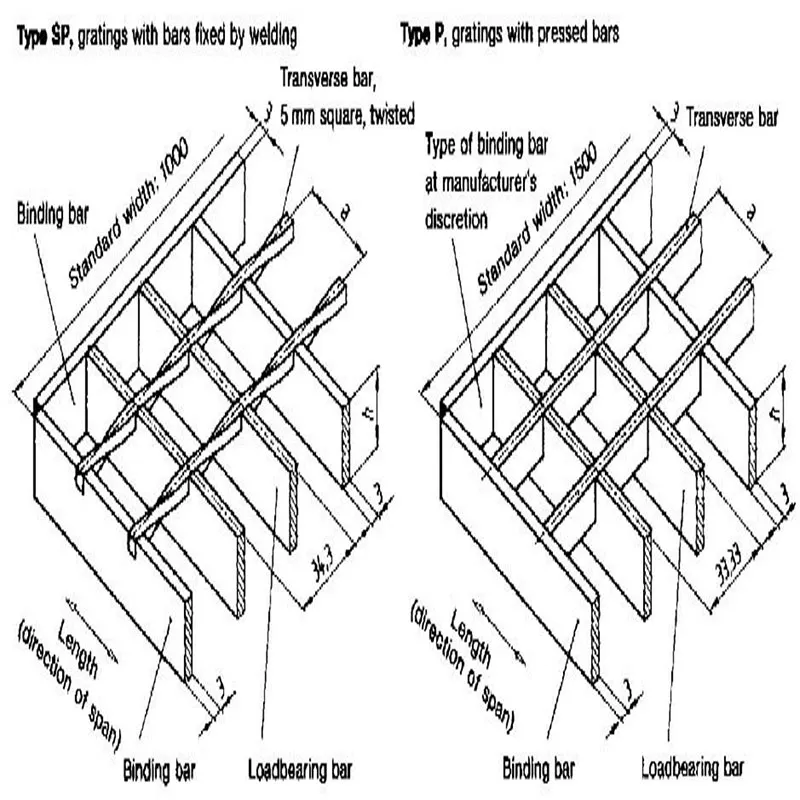

Following the formation of bearing bars, cross rods (often twisted square bars or round bars) are accurately positioned and permanently joined to the bearing bars. The primary joining method for steel grating is resistance welding, where high current and pressure are applied to fuse the metals at their intersection points, creating a strong, monolithic panel. This process is highly automated, ensuring consistent quality and precise spacing of components. Alternatively, some processes utilize press-locking, where cross bars are pressed into pre-punched slots in the bearing bars, relying on high pressure for a secure mechanical interlock. After welding or press-locking, the grating panels are precisely cut to size according to project specifications and design drawings. Edge banding, involving welding flat bars around the perimeter of the grating, is often performed to provide structural integrity, a clean finished appearance, and facilitate safe installation.

The final and crucial step in the manufacturing of I Shape Plain And Serrated Steel Grating is surface treatment, which significantly impacts its service life and aesthetic appeal. Hot-dip galvanization (HDG) is the most common and effective method for steel grating, conforming to international standards such as ASTM A123/A123M. This process involves immersing the fabricated grating in a bath of molten zinc, creating a metallurgically bonded coating that offers superior corrosion protection, especially in harsh industrial environments like petrochemical plants, wastewater treatment facilities, and offshore platforms. Other surface treatments may include painting, powder coating, or electropolishing for stainless steel, selected based on environmental exposure, desired aesthetics, and budgetary considerations. Each batch undergoes rigorous quality control checks, including load testing, slip resistance measurements, and dimensional accuracy, ensuring adherence to standards like ANSI/NAAMM MBG 531-09 for metal bar grating, guaranteeing performance and reliability.

Technical Parameters and Specifications of I Shape Plain And Serrated Steel Grating

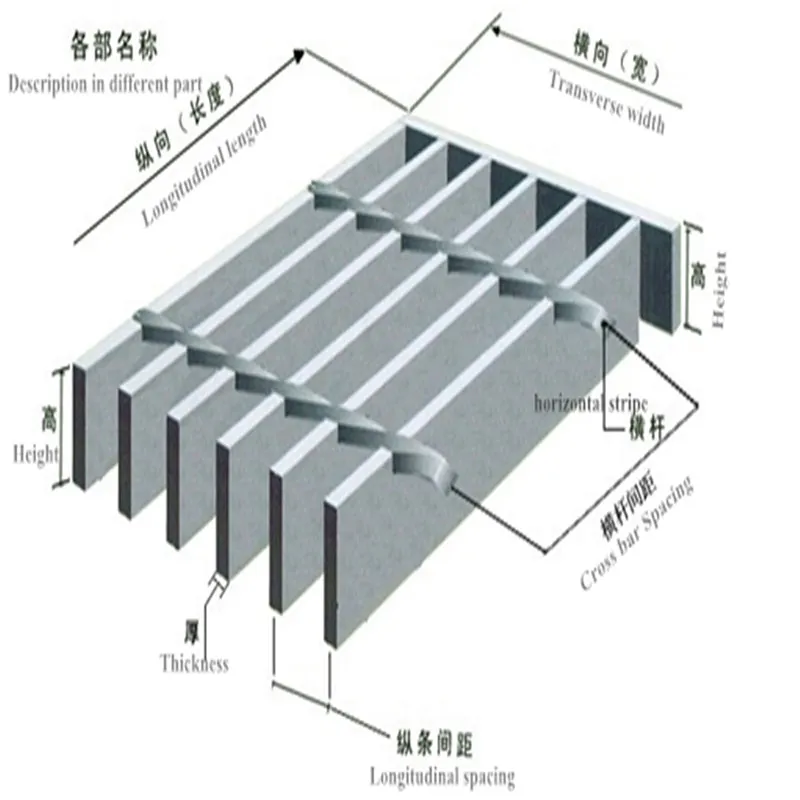

Understanding the technical parameters is essential for specifying the correct I Shape Plain And Serrated Steel Grating for any given project. The "I" shape profile offers a moment of inertia comparable to a flat bar of greater thickness, resulting in excellent load-bearing capabilities with reduced material weight. Key specifications include the bearing bar size (depth and web thickness), bearing bar spacing (pitch), cross rod spacing, and overall panel dimensions. Standard bearing bar depths typically range from 20mm to 100mm, with web thicknesses varying based on the specific load requirements and design calculations. Common bearing bar spacings are 30mm, 40mm, and 60mm center-to-center, while cross rod spacings are typically 50mm or 100mm. These dimensions directly influence the grating's strength, open area, and suitability for various loads and span lengths, making precise specification crucial.

The table below provides typical specifications for I Shape Plain And Serrated Steel Grating, illustrating the variety available to meet diverse industrial demands. These parameters are critical for structural engineers and procurement specialists to ensure compliance with design loads, safety factors, and relevant building codes. The material grade is selected based on environmental exposure and required strength, ensuring optimal performance over the product's extensive service life, which can often exceed 20 years in properly maintained, hot-dip galvanized installations.

| Parameter | Description / Common Range |

|---|---|

| Material Grade | Low Carbon Steel (Q235, A36), Stainless Steel (SS304, SS316), Aluminum 6061-T6 |

| Bearing Bar Size (Depth x Flange x Web) | 25x5x3mm, 32x5x3mm, 40x5x3mm, 50x5x3mm, 60x5x3mm, 75x6x4mm, 100x6x4mm, etc. |

| Bearing Bar Pitch | 30mm, 40mm (Standard for industrial); 19mm (ADA compliant); Custom sizes available |

| Cross Bar Pitch | 50mm, 100mm (Standard); Custom sizes available |

| Surface Type | Plain or Serrated |

| Surface Treatment | Hot-Dip Galvanized (HDG), Painted, Powder Coated, Mill Finish, Electropolished |

| Standard Panel Size | Often 1000x6000mm or 995x6000mm, customizable to project dimensions |

The open area of grating, typically ranging from 70% to 90% depending on the mesh size, is crucial for allowing light, air, and fluids to pass through, while minimizing debris accumulation. This characteristic is particularly beneficial in environments requiring optimal ventilation or drainage, such as wastewater treatment plants or offshore platforms. Furthermore, the structural advantages of the I-shape bearing bar enable longer unsupported spans, reducing the need for intermediate supports and thus simplifying installation and reducing overall project costs. When evaluating suppliers, clients should also consider the supplier's adherence to global manufacturing and testing standards, such as ISO 9001 for quality management systems and relevant ASTM or NAAMM specifications for product performance and material properties.

Applications and Advantages of I Shape Plain And Serrated Steel Grating

The versatility and robust performance of I Shape Plain And Serrated Steel Grating make it indispensable across a wide spectrum of industrial and commercial applications. Its inherent strength-to-weight ratio makes it ideal for walkways, platforms, and mezzanines where structural integrity is paramount without excessive dead load. In petrochemical refineries and chemical processing plants, plain surface I-grating is often used for general access ways and non-slip areas, while the serrated variant ensures superior slip resistance around processing units, pumps, and valves where spills of oils, chemicals, or water are common. Its open design allows for excellent light and air penetration, crucial for safety and ventilation in confined industrial spaces, and facilitates rapid drainage, preventing the accumulation of hazardous liquids.

Beyond traditional industrial settings, this grating finds extensive use in areas demanding high durability and safety. In power generation facilities, including conventional power plants and renewable energy sites, it forms robust service platforms, catwalks, and access stair treads. For water and wastewater treatment plants, the corrosion resistance of galvanized or stainless steel I-grating combined with its drainage capabilities prevents standing water and sludge buildup, significantly extending the service life in corrosive, humid environments. The "I" shape design inherently reduces weight compared to traditional flat bar grating while maintaining or exceeding load-bearing capacity, leading to substantial savings in material costs and shipping, as well as easier, safer installation. This efficiency contributes to lower overall project expenditures and faster construction timelines, critical for large-scale industrial endeavors.

A key advantage of opting for I Shape Plain And Serrated Steel Grating, particularly the serrated variant, is its enhanced safety profile. According to OSHA standards (e.g., 29 CFR 1910.22), walking-working surfaces must be free from recognized hazards, and adequate traction is a fundamental component of this. The serrated surface provides excellent grip even when wet, oily, or icy, significantly reducing the risk of slips and falls, which are a major cause of industrial accidents. This characteristic makes it highly suitable for outdoor stair treads, ramps, and areas prone to environmental exposure. Furthermore, the inherent rigidity of the I-bar minimizes deflection under load, offering a more stable and comfortable walking surface compared to lighter gauge alternatives, enhancing worker comfort and safety during routine operations.

Choosing Your Supplier: Manufacturer Comparison and Customization

Selecting the right manufacturer for I Shape Plain And Serrated Steel Grating is as crucial as selecting the product itself. Reputable manufacturers distinguish themselves through adherence to international quality standards, robust production capabilities, and comprehensive customer support. When evaluating suppliers, consider their certifications (e.g., ISO 9001:2015 for Quality Management Systems, demonstrating a commitment to consistent quality), their experience in serving specific industries, and their capacity for customization. A manufacturer with extensive experience in the B2B sector understands the unique challenges of large-scale industrial projects, including tight deadlines, specific load requirements, and stringent safety protocols. Look for evidence of past successful projects, perhaps through detailed case studies or client testimonials, which demonstrate their capability and reliability in delivering complex orders.

Customization is often a key requirement for complex industrial projects. Leading manufacturers offer bespoke solutions for I Shape Plain And Serrated Steel Grating, including non-standard panel sizes, unique cut-outs for pipes or equipment, specialized banding, and custom surface finishes. For instance, a project requiring grating for a curved walkway will need precision fabrication and bending capabilities. Similarly, environments with extreme corrosive agents might necessitate specific stainless steel grades or specialized coatings beyond standard galvanization, such as duplex stainless steel or custom epoxy paints. A strong partnership with a supplier offering integrated design and engineering support can significantly streamline the procurement process, ensuring that the final product precisely matches the project's technical specifications and operational demands, avoiding costly on-site modifications and delays.

| Feature | I-Bar Grating (I Shape) | Flat Bar Grating |

|---|---|---|

| Strength-to-Weight Ratio | Higher (Efficient load distribution, less material) | Lower (Requires more material for same strength) |

| Material Cost Efficiency | Potentially lower due to optimized material usage and reduced weight | Higher for equivalent load capacity and span |

| Installation & Handling | Lighter panels, easier to handle and install, potentially faster project completion | Heavier panels, may require more effort and equipment for installation |

| Span Capabilities | Longer unsupported spans possible, reducing need for intermediate supports | Shorter spans without additional supports, increasing substructure costs |

| Appearance | Distinctive I-beam look, often preferred for modern industrial aesthetics | Traditional flat bar appearance, common in many applications |

Trust and Reliability: FAQs, Delivery, and Warranty

Frequently Asked Questions (FAQs)

-

Q: What is the primary advantage of I-shape grating over flat bar grating?

A: The I-shape bearing bar offers a higher strength-to-weight ratio, allowing for equivalent load-bearing capacity with less material. This results in lighter panels, easier installation, and potentially lower material and shipping costs for I Shape Plain And Serrated Steel Grating compared to flat bar options of similar load capacity.

-

Q: How do I choose between plain and serrated surfaces for my application?

A: Plain surface is suitable for general applications where slip resistance is not a primary concern, or in aesthetic environments. Serrated surface is essential for areas where enhanced slip resistance is critical, such as wet, oily, or icy conditions, or where stringent safety regulations demand it (e.g., platforms near machinery, outdoor stair treads, ramps).

-

Q: What is the typical lead time for custom orders of I-shape grating?

A: Lead times for custom orders of I Shape Plain And Serrated Steel Grating vary based on complexity, quantity, and current production schedules. Typically, standard custom orders can range from 3-6 weeks after design approval and receipt of deposit. Expedited options may be available for urgent projects, subject to a feasibility review.

-

Q: What warranty is offered on your steel grating products?

A: Our steel grating products typically come with a comprehensive warranty covering manufacturing defects and material integrity for a specified period, often 1-5 years depending on the product, material, and specific application. Full warranty details are provided with each quotation and contract, ensuring peace of mind for our valued clients regarding their investment.

Delivery and Logistics

Efficient delivery and logistics are critical components of successful project execution. As a professional manufacturer of I Shape Plain And Serrated Steel Grating, we prioritize robust supply chain management to ensure timely and secure delivery worldwide. Our logistics team works closely with clients to coordinate shipping methods, whether by sea, rail, or truck, optimizing routes and packaging for maximum cost-efficiency and product protection against transit damage. We provide clear communication regarding estimated delivery dates and tracking information, supporting project managers in their planning and scheduling. For large-scale industrial projects, specialized packaging and bulk shipping options are available to handle the volume and weight of grating panels effectively and safely.

After-Sales Support and Commitment

Our commitment to clients extends far beyond the point of sale. We offer comprehensive after-sales support, including technical consultation for installation best practices, detailed maintenance guidelines, and prompt assistance with any post-delivery inquiries or operational concerns. Our dedicated customer service team is available to address questions, provide troubleshooting advice, and ensure long-term satisfaction with your I Shape Plain And Serrated Steel Grating investment. This commitment to continuous support underscores our role as a trusted partner in industrial infrastructure development, building long-term relationships based on reliability, superior product quality, and mutual success in achieving project goals.

Conclusion: The Strategic Choice for Modern Industrial Demands

In summary, I Shape Plain And Serrated Steel Grating represents a technologically superior and economically advantageous choice for a broad array of industrial and commercial applications. Its distinctive "I" beam profile delivers unparalleled strength-to-weight ratio, contributing to reduced material consumption, lower transportation costs, and simplified installation processes. The option of plain or serrated surfaces ensures optimal performance across varying environmental conditions, from general access areas to critical zones requiring maximum slip resistance, thereby enhancing operational safety. By understanding its advanced manufacturing process, precise technical specifications, and diverse application benefits, decision-makers can confidently specify this grating to enhance safety, improve operational efficiency, and achieve long-term durability in their infrastructure projects. Partnering with a reputable manufacturer that offers extensive customization capabilities, adherence to international standards, and robust after-sales support is crucial to realizing the full potential of this high-performance material and ensuring project success.

References

- ASTM International. (Current Standard). ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- National Association of Architectural Metal Manufacturers (NAAMM). (Current Edition). NAAMM MBG 531: Metal Bar Grating Manual.

- Occupational Safety and Health Administration (OSHA). (Current Regulation). 29 CFR 1910.22: Walking/Working Surfaces.

- ISO 9001:2015. Quality management systems — Requirements. International Organization for Standardization.

Latest News

-

Factory Supply 6063 Anodized Aluminum Grating Walkway Platform

NewsAug.21,2025

-

Hot Dip Galvanized Serrated I Bar Grating | 25x3, 25x5, 30x3 Mesh

NewsAug.19,2025

-

Hot Dipped Galvanized Barbed Wire Mesh Fencing (10-50kg)

NewsAug.18,2025

-

450mm Galvanized Concertina Razor Wire: BTO/CBT Types

NewsAug.17,2025

-

Aluminium Corner Bead: Durable Tile & Plaster Edge Protection

NewsAug.16,2025

-

Durable PVC Coated Wire Mesh Rolls for Fencing

NewsAug.15,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA