আগস্ট . 12, 2025 04:20 Back to list

Competitive Compound Steel Grating: Superior Strength & Value

The Strategic Advantage of Advanced Compound Steel Grating Solutions

In the demanding landscape of modern industrial infrastructure, the selection of robust, durable, and high-performance materials is paramount. Among these, Competitive Compound Steel Grating stands out as a superior choice, offering unparalleled strength, corrosion resistance, and versatility. This innovative material combines the high load-bearing capacity of steel grating with a checker plate or other surface material, providing enhanced anti-slip properties and protection against debris accumulation. Its adoption is increasingly driven by stringent safety regulations, the need for extended service life in harsh environments, and the pursuit of operational efficiencies across various sectors. The global market for industrial gratings is experiencing steady growth, fueled by expansion in petrochemical, energy, and municipal infrastructure projects, all of which prioritize resilient and low-maintenance solutions.

Understanding the intricacies of this specialized product, from its fundamental design principles to its sophisticated manufacturing processes and diverse applications, is crucial for B2B decision-makers. This comprehensive guide delves into the technical aspects, industry relevance, and strategic benefits of implementing advanced compound steel grating, ensuring that engineers, procurement specialists, and project managers can make informed choices that contribute to long-term asset integrity and operational excellence.

Unpacking the Engineering: Structure and Manufacturing Process

Core Structure and Materials

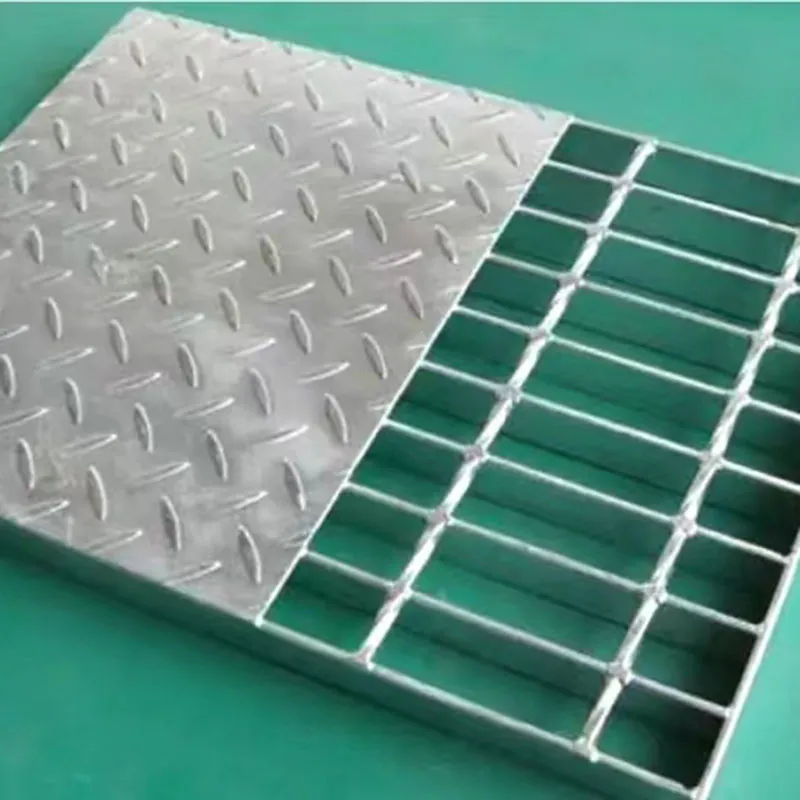

At its core, Competitive Compound Steel Grating is a composite structure typically comprising a load-bearing steel bar grating fused with a top plate, often a diamond pattern plate or plain plate. The steel grating component is generally manufactured from low carbon steel (e.g., Q235, A36, SS400) or stainless steel (e.g., 304, 316, 316L) for superior corrosion resistance in specific environments. The load-bearing bars are typically flat steel bars, and cross bars (twisted square bars or round bars) are resistance welded, pressure locked, or swage locked to them, creating a rigid and strong grid. The top plate, usually 3mm to 10mm thick, is then welded to the grating, forming a robust, non-slip surface that prevents small objects from falling through while offering enhanced aesthetic appeal and foot traffic comfort. This dual-layer design optimizes both structural integrity and surface functionality.

Detailed Manufacturing Process

The production of high-quality Competitive Compound Steel Grating involves a meticulous multi-stage process designed to ensure structural integrity, precise dimensions, and optimal surface characteristics. The primary manufacturing methods for the base steel grating include automated pressure welding, which ensures uniform and strong joints between the bearing bars and cross bars, or press-locking for non-welded applications requiring specific aesthetic or material properties.

- Material Preparation: High-grade steel coils or plates are cut into precise bearing bar and cross bar dimensions. For the top plate, sheets of required thickness are prepared, often through a cold-rolling or hot-rolling process depending on the steel type and desired finish.

- Grating Fabrication: The bearing bars are precisely positioned, and cross bars are then integrated. In automated resistance welding, immense pressure and electric current are applied, fusing the metals at their intersections without the need for filler material, creating exceptionally strong and durable joints.

- Compound Layer Integration: The prepared top plate, often a chequer plate for enhanced slip resistance, is then carefully welded onto the surface of the fabricated steel grating. This welding process is critical and must ensure a strong, continuous bond that can withstand significant loads and environmental stresses.

- Finishing and Surface Treatment: Post-fabrication, the grating undergoes various finishing processes. This often includes hot-dip galvanization (HDG) in accordance with standards like ASTM A123/A123M or ISO 1461, providing a robust, sacrificial zinc coating that offers superior corrosion protection. Other treatments may include painting, powder coating, or electropolishing for stainless steel variants.

- Quality Control & Inspection: Each batch of compound steel grating undergoes rigorous inspection. This includes dimensional checks (conforming to standards like ANSI/NAAMM MBG 531, BS 4592), load-bearing capacity tests, slip resistance testing, and visual inspection for weld integrity and surface finish. Only products meeting stringent quality assurance protocols are approved for dispatch, ensuring compliance with global engineering and safety benchmarks.

Key Technical Parameters and Performance Specifications

Selecting the appropriate Competitive Compound Steel Grating necessitates a thorough understanding of its technical specifications. These parameters dictate the product's suitability for specific load requirements, environmental conditions, and operational demands. Below is a detailed table outlining typical specifications for compound steel grating, providing a clear reference for technical evaluation.

Figure 1: Illustration of a typical installation of Competitive Compound Steel Grating in a heavy-duty industrial environment.

| Parameter | Typical Range/Value | Relevant Standard |

|---|---|---|

| Bearing Bar Size (Width x Thickness) | 25x3mm to 100x8mm | ANSI/NAAMM MBG 531, BS 4592 |

| Bearing Bar Pitch | 30mm, 40mm, 60mm, custom | ISO 9001 Guidelines |

| Cross Bar Pitch | 50mm, 100mm, custom | ISO 9001 Guidelines |

| Top Plate Thickness | 3mm to 10mm | ASTM A36, JIS G3101 |

| Material Grades (Grating & Plate) | Q235, Q345, A36, SS400 (Carbon Steel); 304, 316, 316L (Stainless Steel) | ASTM A1011/A1011M, ASTM A240 |

| Surface Treatment | Hot-dip Galvanized, Painted, Self-color | ASTM A123/A123M, ISO 1461 |

| Load Bearing Capacity | Varies based on span and bar size (e.g., 5 kPa to 50 kPa distributed load) | AS 1657, Eurocode 1 |

| Slip Resistance | Excellent, R10-R13 ratings possible with patterned plate | DIN 51130, AS/NZS 4586 |

| Typical Panel Size | Up to 995mm x 6000mm (custom sizes available) | Manufacturer Specific |

These parameters are critical for engineers designing platforms, walkways, and covers where both structural strength and a solid, secure walking surface are required. The ability to customize dimensions and materials ensures that Competitive Compound Steel Grating can be precisely tailored to meet the unique demands of any project, optimizing performance and safety.

Diverse Applications and Sector-Specific Advantages

The versatility of Competitive Compound Steel Grating makes it an indispensable material across a wide array of industrial and commercial applications. Its composite design addresses the limitations of standard open-mesh grating, providing a solid, secure surface while retaining the structural benefits of steel.

Figure 2: Custom-fabricated Competitive Compound Steel Grating panels for a modern wastewater treatment facility.

Petrochemical and Oil & Gas: In these highly corrosive and often hazardous environments, compound steel grating is crucial for platforms, walkways, and trench covers. Its solid top plate prevents tools, small components, and harmful chemicals from falling through, enhancing safety. When treated with hot-dip galvanization or made from stainless steel, it offers exceptional resistance to chemical corrosion and severe weather, significantly reducing maintenance costs and ensuring long service life, which translates directly into operational energy savings by avoiding frequent replacements.

Metallurgy and Mining: Heavy-duty compound grating is ideal for areas subjected to extreme loads and abrasion, such as processing plants, smelters, and ore handling facilities. The robust construction supports heavy machinery and foot traffic, while the closed surface offers protection against falling debris and facilitates easier cleanup of spillage, contributing to a cleaner and safer working environment.

Power Generation: From conventional power plants to renewable energy facilities, Competitive Compound Steel Grating is used for access platforms, mezzanines, and stair treads. Its non-slip surface ensures worker safety, especially in areas prone to moisture or grease. The solid top prevents hot embers, ash, or dust from affecting lower levels, demonstrating its critical role in maintaining safety and operational integrity.

Water Treatment and Wastewater Management: In these applications, the grating must withstand constant exposure to moisture, chemicals, and microbial activity. Stainless steel compound grating, specifically grades like 316L, provides superior corrosion resistance. The closed surface also minimizes splash-through, improving hygiene and preventing accidental contact with treated or untreated water, which is a key advantage for health and safety compliance.

Marine and Offshore Structures: On offshore drilling rigs, ships, and port facilities, the material endures saltwater corrosion, heavy impacts, and constant movement. Compound grating offers a durable, non-slip deck surface, essential for personnel safety and preventing equipment loss overboard. Its structural resilience ensures longevity in the most challenging marine conditions.

Technical Advantages and Performance Benchmarks

The design of Competitive Compound Steel Grating offers distinct technical advantages over traditional open steel grating or plain plate flooring, making it a preferred choice for demanding industrial applications.

Figure 3: Close-up demonstrating the fusion of the checkered top plate with the underlying steel grating.

- Enhanced Load Distribution: The integrated top plate, particularly when welded to the bearing bars, significantly aids in distributing concentrated loads over a larger area of the grating. This reduces stress on individual bearing bars, enhancing the overall load-bearing capacity and preventing localized deflection or deformation, critical for areas with heavy machinery or frequent heavy pedestrian traffic.

- Superior Slip Resistance: When a checkered or diamond pattern top plate is used, the surface provides excellent multi-directional slip resistance, even in wet, oily, or icy conditions. This dramatically improves worker safety and reduces the risk of accidents, aligning with international safety standards like DIN 51130 (R-values) and AS/NZS 4586 (coefficient of friction).

- Debris Prevention and Containment: The solid top plate prevents small tools, bolts, debris, and even liquids from falling through to levels below. This is invaluable in multi-story facilities, protecting equipment, preventing contamination, and improving overall cleanliness and safety.

- Reduced Noise and Vibration: The composite structure can absorb some level of noise and vibration compared to open grating, contributing to a more comfortable working environment, especially in high-traffic or machinery-intensive areas.

- Improved Aesthetics and Comfort: The solid surface offers a more finished and visually appealing look, suitable for public areas or facilities where appearance is also a consideration. It also provides a more comfortable walking surface, particularly for individuals in certain types of footwear.

- Corrosion Protection: When hot-dip galvanized or fabricated from stainless steel, Competitive Compound Steel Grating offers exceptional long-term resistance to environmental degradation, including chemical attack, atmospheric corrosion, and saltwater exposure. The typical galvanization thickness for industrial applications often exceeds 85 microns, providing decades of protection without significant maintenance.

These inherent advantages underline why compound steel grating is increasingly specified by engineers for projects where conventional solutions fall short in terms of safety, durability, or operational efficiency.

Choosing Your Partner: Manufacturer Comparison and Custom Solutions

The market for Competitive Compound Steel Grating is served by numerous manufacturers, but identifying a reliable and capable partner is crucial for project success. A discerning approach involves evaluating not just product specifications but also manufacturing capabilities, quality assurance, and customer support.

Figure 4: Advanced manufacturing facility dedicated to producing high-precision steel grating products.

Key Factors in Manufacturer Selection:

- Certifications & Compliance: Verify adherence to international standards like ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and specific product standards such as ANSI/NAAMM MBG 531, AS 1657, BS 4592, and EN ISO 1461 for galvanization. These certifications are a strong indicator of consistent quality and reliable processes. Our factory has maintained ISO 9001 certification for over 15 years, demonstrating long-term commitment to quality.

- Manufacturing Expertise & Technology: Assess the manufacturer's production facilities. Leading companies utilize automated resistance welding machines, precise cutting equipment, and advanced galvanizing plants to ensure uniform quality and efficient production. Expertise in various welding techniques (e.g., CO2 welding, submerged arc welding for larger components) for the compounding process is also vital.

- Customization Capabilities: Not all projects fit standard dimensions. A top-tier manufacturer should offer extensive customization options, including specific bearing bar spacing, cross bar types, panel dimensions, cutout requirements, banding, and a variety of top plate patterns and materials. This includes providing detailed shop drawings and engineering support to ensure precise fit and optimal performance.

- Project Experience & Case Studies: Review past projects and client testimonials. Experience with large-scale industrial projects, particularly in relevant sectors like petrochemical or energy, indicates a manufacturer's capacity to handle complex demands and deliver on time. We have successfully supplied thousands of tons of grating for major infrastructure projects worldwide, including a recent large-scale water treatment plant expansion in the Middle East.

- After-Sales Support & Warranty: A commitment to product quality extends beyond delivery. Inquire about warranty periods (typically 5-10 years for structural integrity), spare parts availability, and technical support for installation or maintenance. Comprehensive support reflects confidence in their product and dedication to customer satisfaction.

Tailored Customization Solutions:

For complex industrial projects, off-the-shelf solutions rarely suffice. A specialized manufacturer of Competitive Compound Steel Grating should provide end-to-end customization, from initial design consultation to detailed engineering drawings and on-site technical assistance. This includes:

- Material Selection Guidance: Advising on the optimal steel grade (carbon, stainless 304/316/316L) and surface treatment based on the operating environment (e.g., highly corrosive acids, saltwater, extreme temperatures).

- Load & Deflection Calculations: Performing precise calculations to ensure the grating meets specific live and dead load requirements with minimal deflection, adhering to relevant building codes and safety factors.

- Panel Design & Cutouts: Designing panels with custom shapes, cutouts for pipes, columns, and equipment, and integrating specialized openings for access or ventilation.

- Attachment Methods: Offering various clipping systems, weld-down options, or custom anchorage designs to suit structural requirements and ease of installation.

- Integrated Solutions: Providing comprehensive solutions that include compatible stair treads, handrail systems, and custom fabrication to ensure seamless integration into the overall project.

Ensuring Trust and Reliability: Quality, Warranty, and Support

In the B2B sector, particularly for critical infrastructure components like Competitive Compound Steel Grating, trust is built on verifiable quality, clear commitments, and dependable support. Our approach focuses on exceeding industry benchmarks to provide clients with absolute confidence in their investment.

Figure 5: Rigorous quality control checks are performed at every stage of the Competitive Compound Steel Grating manufacturing process.

Comprehensive Quality Assurance & Testing

Our manufacturing processes are meticulously managed under an ISO 9001 certified quality management system. Every batch of Competitive Compound Steel Grating undergoes a multi-point inspection protocol. This includes:

- Material Traceability: All raw materials are sourced from certified suppliers and undergo incoming inspection, with full traceability back to mill certificates.

- Dimensional Accuracy: Utilizing precision measurement tools, we ensure all grating dimensions, bearing bar and cross bar pitches, and top plate dimensions comply strictly with design specifications and relevant industry standards.

- Weld Integrity: Visual inspection and, where necessary, non-destructive testing (NDT) such as ultrasonic testing (UT) or dye penetrant inspection (DPI) are performed on welds joining the top plate to the grating, ensuring robust and lasting bonds.

- Surface Finish & Corrosion Protection: For galvanized products, galvanization thickness is measured using calibrated gauges to confirm compliance with ASTM A123/A123M or ISO 1461. For painted or coated products, adhesion tests and thickness checks are performed.

- Load Testing: Representative samples are subjected to deflection and ultimate load tests to confirm they meet or exceed specified load-bearing capacities, providing real-world performance validation.

Delivery Timelines and Logistics

Understanding the critical nature of project schedules, we maintain efficient production lines and robust supply chain management. Typical lead times for standard Competitive Compound Steel Grating orders range from 2-4 weeks, depending on volume and customization requirements. For large or highly specialized orders, a detailed project timeline is provided at the quotation stage. We coordinate closely with logistics partners to ensure timely and secure delivery worldwide, offering various shipping options including FOB, CIF, and DDP to accommodate client preferences.

Warranty and Customer Support

We stand behind the quality of our products with a comprehensive structural warranty, typically extending for 5 to 10 years from the date of purchase, against manufacturing defects and premature material failure under normal operating conditions. Our dedicated customer support team is available to assist with technical queries, installation guidance, and any post-delivery concerns. This commitment ensures peace of mind and reinforces our position as a trusted partner in industrial grating solutions.

Frequently Asked Questions (FAQ)

Q1: What is the primary benefit of Competitive Compound Steel Grating over standard steel grating?

A1: The primary benefit is the combination of high load-bearing capacity with a solid, slip-resistant surface. This prevents small items from falling through, enhances safety by providing better traction, and offers a more uniform appearance, making it ideal for walkways, platforms, and trench covers where an open mesh isn't suitable.

Q2: How does the surface treatment affect the longevity of the grating?

A2: Hot-dip galvanization (HDG) in accordance with ASTM A123/A123M or ISO 1461 provides a robust zinc coating that offers superior corrosion resistance, significantly extending the service life of carbon steel grating in harsh environments. For extremely corrosive conditions, stainless steel (e.g., 316L) is recommended, offering inherent corrosion resistance without additional coatings.

Q3: Can Competitive Compound Steel Grating be customized for specific project requirements?

A3: Yes, comprehensive customization is a key offering. This includes variations in bearing bar size and pitch, cross bar type and pitch, top plate thickness and pattern (e.g., plain, diamond), overall panel dimensions, custom cutouts for pipes or columns, and choice of material (carbon steel, stainless steel grades).

Q4: What industries most commonly use this type of grating?

A4: It is widely used in industries such as petrochemical, oil and gas, power generation, metallurgy, mining, wastewater treatment, and marine & offshore applications. Any environment requiring heavy-duty, slip-resistant, and debris-containing flooring or platforms can benefit from Competitive Compound Steel Grating.

Q5: What certifications should I look for when selecting a manufacturer?

A5: Look for manufacturers certified to ISO 9001 for quality management. Additionally, ensure their products comply with relevant international standards such as ANSI/NAAMM MBG 531 (USA), BS 4592 (UK), AS 1657 (Australia), and ISO 1461 for hot-dip galvanization. These certifications and compliance indicators reflect a commitment to high-quality manufacturing and product performance.

References

- National Association of Architectural Metal Manufacturers (NAAMM). (2007). Metal Bar Grating Manual (MBG 531).

- ASTM International. (2015). ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- International Organization for Standardization (ISO). (2000). ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods.

- British Standards Institution (BSI). (2007). BS 4592-1: Grating and flooring – Part 1: Open bar gratings. Specification.

- Standards Australia. (2018). AS 1657: Fixed platforms, walkways, stairways and ladders – Design, construction and installation.

- Deutsches Institut für Normung (DIN). (2002). DIN 51130: Testing of floor coverings; determination of the anti-slip property; wet-loaded ramp method.

Latest News

-

Factory Supply 6063 Anodized Aluminum Grating Walkway Platform

NewsAug.21,2025

-

Hot Dip Galvanized Serrated I Bar Grating | 25x3, 25x5, 30x3 Mesh

NewsAug.19,2025

-

Hot Dipped Galvanized Barbed Wire Mesh Fencing (10-50kg)

NewsAug.18,2025

-

450mm Galvanized Concertina Razor Wire: BTO/CBT Types

NewsAug.17,2025

-

Aluminium Corner Bead: Durable Tile & Plaster Edge Protection

NewsAug.16,2025

-

Durable PVC Coated Wire Mesh Rolls for Fencing

NewsAug.15,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA