1. Introduction

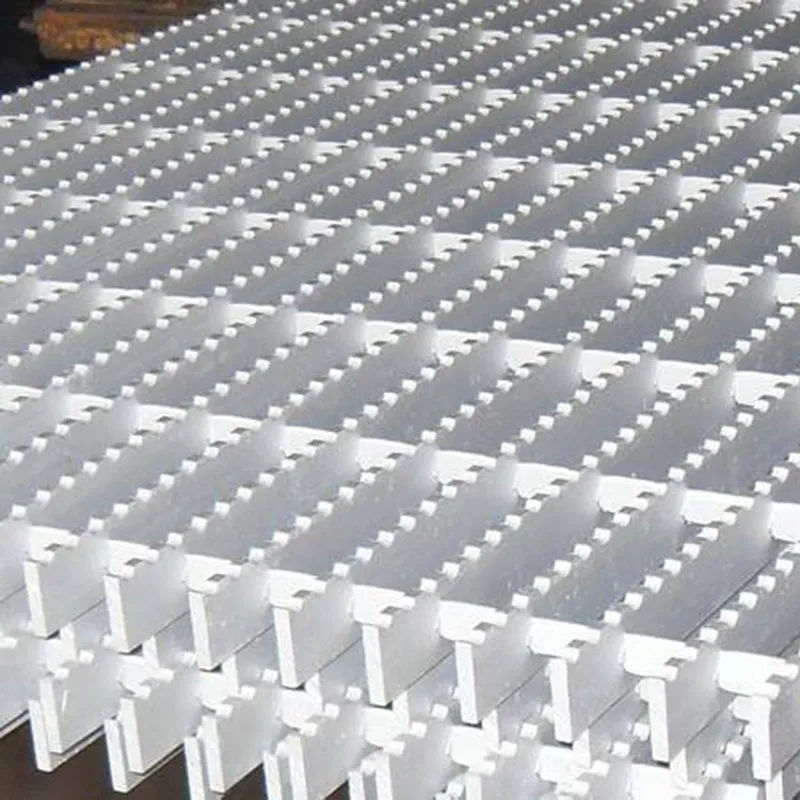

As the demands for durable, lightweight, and corrosion-resistant walkway solutions increase across industries, the Factory Supply Walkway Platform 6063 Anodized Aluminum Grating rises as a preferred choice for facilities engineers and project designers worldwide. Manufactured from premium 6063 anodized aluminum alloy, this grating offers an optimal balance between structural performance and resilience, making it an excellent option for high-traffic platforms, walkways, and industrial environments.

Product Overview

- Name: Factory Supply Walkway Platform 6063 Anodized Aluminum Grating

- Material: ASTM B221, 6063 or 6061 Aluminum Alloy

- Main Features: Lightweight, high strength, excellent anti-slip, good corrosion & rust resistance, multiple surface finishes (smooth/serrated)

- Typical Application: Power plant walkways, platform ceilings, outdoor curtain walls, chemical plants, offshore structures

- Product URL: Detailed Specification & Enquiry

metals@chengsenchina.com

+86 15733154345

B1213 GLOBAL CENTER,

NO.226 ZHONGHUA NORTH STREET,

SHIJIAHUANG, CHINA

2. Industry Trends & Market Analysis

The global demand for industrial grating products such as the Factory Supply Walkway Platform 6063 Anodized Aluminum Grating has risen steadily in the last decade. Key market drivers include:

- Stringent safety regulations across the construction, energy, and chemical sectors

- Growing preference for corrosion-resistant and easily maintainable materials

- Expanded use of lightweight structural materials in both industrial and architectural applications (Source)

- Significant adoption in offshore industries due to excellent rust resistance of anodized aluminum

According to construction industry forums, aluminum grating is forecasted to see 6-7% annual growth by 2030, with rising market share in Asia-Pacific and North America (Markets & Markets Report).

3. Technical Parameters Overview

The Factory Supply Walkway Platform 6063 Anodized Aluminum Grating features industry-leading technical parameters, engineered for superior performance in demanding environments. Below is a consolidated comparison of key parameters:

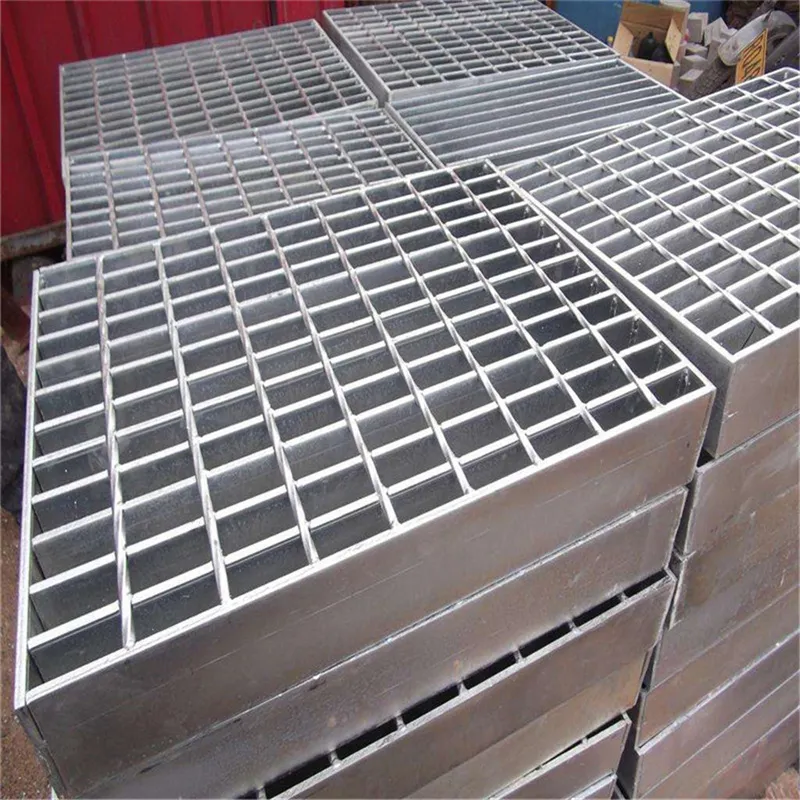

| Parameter | 6063 Anodized Aluminum Grating | Standard Steel Grating | Notes |

|---|---|---|---|

| Material Standard | ASTM B221, 6063/6061 Alloy | ASTM A36 / Q235 | Aluminum – lightweight & corrosion-resistant |

| Surface Finish | Anodized, Smooth/Serrated | Painted, Galvanized | Anodizing enhances durability |

| Weight (kg/m²) | 7.2–10.5 | 26–35 | ~65% Lighter |

| Load Capacity (kN/m²) | 3.0–10.5 | 4.2–16.2 | Comparable to steel |

| Slip Resistance | High, serrated option | Medium | Safe for walkways |

| Corrosion Resistance | Excellent | Good (depends on coating) | Key for industrial use |

| Life Span (yrs) | 20–30+ | 10–20 | Reduced maintenance cost |

| Fire Resistance | Non Combustible | Non Combustible | Compliant with codes |

4. Application Scenarios

With its superior technical features, the Factory Supply Walkway Platform 6063 Anodized Aluminum Grating is widely adopted in:

- Power Plants: Elevated walkways, maintenance platforms, cable trench covers, turbine rooms

- Petrochemical & Offshore Facilities: Corrosion-prone outdoor walkways, marine oil rigs, chemical storage zones

- Transportation Infrastructure: Footbridges, railway overpasses, metro platforms

- Architectural Spaces: Ventilated façade ceilings, sun shades, exterior curtain walls, atrium floors

- Electronics & Cleanroom Construction: Maintenance access areas with high cleanliness requirements

- Food Processing: Hygienic platforms, anti-slip safety areas

- Mining & Heavy Industry: Corrosive zone platforms, equipment maintenance decks

Its versatility, competitive installation cost, and diverse specification range allow it to fit both new projects and facility retrofits. According to industry analysis on Engineering.com, aluminum grating adoption is rising over steel in projects where weight reduction and reduced maintenance are critical.

5. Detailed Product Advantages

- Significantly Lighter Structure: At only 7.2–10.5 kg/m², Factory Supply Walkway Platform 6063 Anodized Aluminum Grating eases installation and reduces dead load on supporting structures, enabling longer spans or lighter framing systems.

- Superb Corrosion Resistance: Anodized 6063 alloy forms a dense oxide layer, protecting the metal against oxidation, even in saline or acid-alkali environments (JOM, ASM International).

- Safety: Serrated or smooth anti-slip surface options surpass industry slip resistance standards (see OSHA Guidelines).

- Modular & Customizable: Multiple mesh spacings, heights, and panel sizes for tailored solutions, including architectural pattern designs.

- Low Lifecycle Cost: Minimal maintenance needs, high durability, and recyclability make it a green, cost-effective choice long term.

6. Professional FAQ: Industry Terminology Explained

Q1: What is the ASTM B221 6063 Aluminum Alloy used in this grating?

A: ASTM B221 6063 is a precipitation-hardened aluminum alloy, offering high corrosion resistance, good extrudability, and a smooth anodized surface. It is the preferred choice for architectural and walkway applications (AZoM: 6063 Alloy Data).

Q2: How does anodizing improve aluminum grating performance?

A: Anodizing creates a uniform oxide protective layer increasing durability, hardness, and corrosion resistance—ideal for aggressive outdoor or chemical settings.

Q3: What mesh types are available for Factory Supply Walkway Platform 6063 Anodized Aluminum Grating?

A: Both swage-locked and pressure-locked meshings are standard. Mesh spacing like 30mm × 100mm or 40mm × 100mm are common, with customized options for load or ventilation demands.

Q4: Are there standard installation practices or codes for aluminum grating?

A: Installation should follow international codes such as ASTM standards and local building codes, including proper anchoring, bearing bar alignment, and slip protection.

Q5: What’s the difference between smooth and serrated surfaces?

A: Smooth surfaces are easy to clean and suitable for regular foot traffic; serrated types boost slip resistance—especially recommended for oily, wet, or icy areas.

Q6: What typical panel sizes are produced?

A: Panels are usually manufactured in modules such as 1000mm × 6000mm or 1200mm × 4000mm, but can be customized to fit project requirements for efficient installation.

Q7: How do you maintain anodized aluminum grating in aggressive environments?

A: Routine cleaning with mild detergents and inspection for damage is sufficient. Anodized coating reduces the need for repainting or intensive repairs, minimizing maintenance cycles.

7. Why Choose SHIJIAZHUANG CHENGSEN TRADING CO., LTD.?

- Expertise in Factory Supply Walkway Platform 6063 Anodized Aluminum Grating production and export

- ISO-certified quality, strict raw material sourcing, and precision manufacturing

- Comprehensive product support and fast global delivery

- Fully customizable specification options

- Technical team with decades of industry experience

- Proven reliability—trusted by clients across energy, petrochemical, and infrastructure sectors

8. Conclusion

The Factory Supply Walkway Platform 6063 Anodized Aluminum Grating plays a vital role in modern industrial and infrastructure facilities, making operations safer, more cost-effective, and easier to maintain. Combining advanced alloy technology, precision surface treatment, and thoughtful engineering, it stands as the optimal alternative to traditional steel gratings—especially where aggressive environments, strict anti-slip requirements, or lightweight construction is essential.

For detailed technical datasheets, CAD drawings, or a customized quotation for your project, contact SHIJIAZHUANG CHENGSEN TRADING CO., LTD. via metals@chengsenchina.com or Call +86 15733154345. Our engineering team offers full support from design optimization to after-sales service.

SHIJIAZHUANG CHENGSEN TRADING CO., LTD. is your trusted partner for Factory Supply Walkway Platform 6063 Anodized Aluminum Grating serving demanding industries worldwide.

- “Aluminum Alloys for Structural Applications”, JOM, ASM International

- “Global Aluminum Grating Market Trends”, Markets & Markets Industry Report

- “Engineering Safe Walkways and Platforms”, Engineering.com Article

- “6063 Aluminum Alloy Data Sheet”, AZoM Materials Journal

- “Steel Grating Industry Forum”, steelgrating.org

- “OSHA Walking-Working Surfaces Standard”, OSHA.gov