ਅਗਃ . 21, 2025 21:40 Back to list

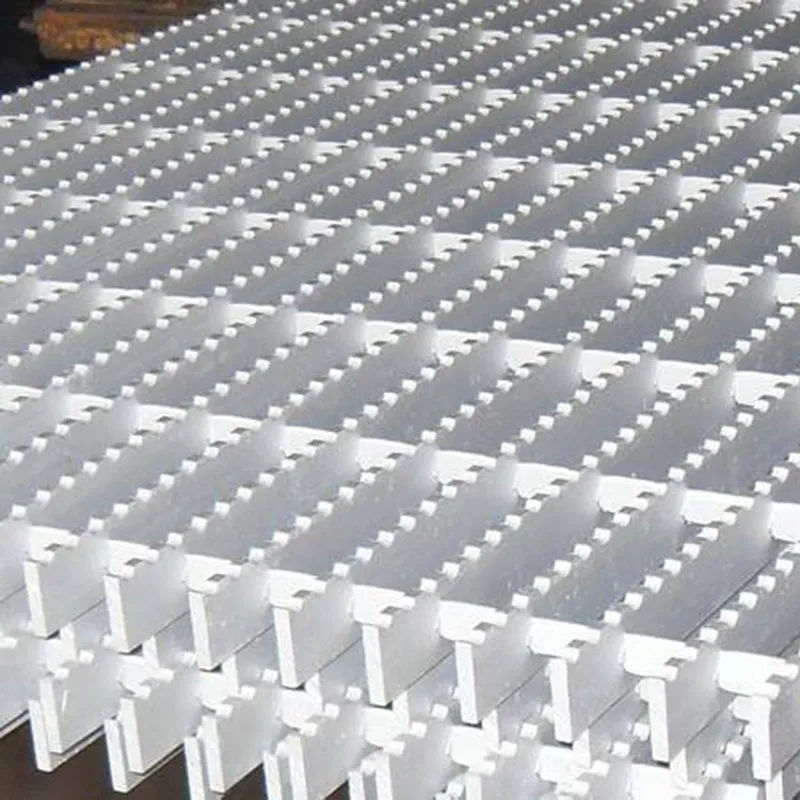

Factory Supply 6063 Anodized Aluminum Grating Walkway Platform

Advancing Industrial Safety and Efficiency with Premium Aluminum Grating Solutions

In the intricate landscape of modern industrial infrastructure, the demand for materials that offer unparalleled strength, durability, and corrosion resistance while remaining lightweight is paramount. Among these, aluminum grating stands out as a superior choice, particularly for applications requiring robust and long-lasting walkway platforms. This comprehensive guide delves into the specifics of Factory Supply Walkway Platform 6063 Anodized Aluminum Grating, exploring its technical prowess, diverse applications, and the strategic advantages it offers to B2B decision-makers and technical professionals.

The selection of the right material for industrial flooring, walkways, and platforms significantly impacts operational safety, maintenance costs, and overall project longevity. Traditional materials often fall short in challenging environments characterized by moisture, chemical exposure, or extreme temperatures. Aluminum, specifically the 6063 alloy, coupled with a meticulous anodizing process, provides a solution that addresses these critical needs, ensuring structural integrity and extended service life across a multitude of sectors.

This article aims to provide an in-depth technical understanding, covering everything from the manufacturing intricacies and material science behind 6063 aluminum to its practical applications and economic benefits. We will also incorporate real-world data, technical specifications, and insights gained from extensive industry experience to underscore the value proposition of these advanced grating systems.

Understanding 6063 Anodized Aluminum Grating: Material Science and Industrial Trends

The foundation of a superior walkway platform lies in its core material. Aluminum alloy 6063 is a magnesium and silicon alloy, belonging to the 6xxx series, which is known for its excellent extrudability, good strength-to-weight ratio, and high resistance to corrosion. It is widely recognized as an architectural alloy, often employed in applications where surface finish is critical and complex shapes are required. Its chemical composition typically includes 0.20-0.60% Silicon (Si), 0.45-0.90% Magnesium (Mg), along with trace amounts of Iron (Fe), Copper (Cu), Manganese (Mn), Chromium (Cr), Zinc (Zn), and Titanium (Ti), with the remainder being Aluminum (Al).

The choice of 6063 for grating ensures that the final product possesses inherent advantages such as superior weldability, formability, and a natural protective oxide layer. This native oxide layer, though thin, provides a baseline of corrosion resistance. However, for industrial applications demanding superior longevity and resilience against harsh elements, an additional surface treatment is indispensable: anodizing.

The Anodizing Process: Enhancing Durability and Performance

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts, particularly aluminum. This process creates a porous, uniform, and much thicker aluminum oxide layer than the one formed naturally. The benefits of anodizing are multi-faceted:

- Enhanced Corrosion Resistance: The thicker, denser oxide layer provides significantly improved protection against environmental degradation, including exposure to saltwater, industrial chemicals, and atmospheric pollutants.

- Increased Surface Hardness: Anodized surfaces are considerably harder than bare aluminum, improving resistance to abrasion and wear, which is crucial for high-traffic walkway platforms.

- Improved Adhesion for Coatings: The porous nature of the anodized layer allows for better adhesion of paints and sealants, although for grating, the anodized finish itself often suffices.

- Aesthetic Appeal: Anodizing can provide a clean, metallic finish or be dyed to various colors, offering aesthetic flexibility for architectural or visible industrial applications.

- Electrical Insulation: The anodized layer is non-conductive, which can be an important safety feature in certain environments.

The combination of 6063 aluminum alloy and the anodizing process yields a grating product that meets the stringent requirements of modern industry for safety, longevity, and low maintenance. This synergistic approach significantly extends the product's service life, reducing the total cost of ownership over time.

Industry Trends Driving Adoption

The industrial sector is witnessing a growing trend towards sustainable, lightweight, and durable materials. This shift is driven by several factors:

- Safety Regulations: Increasing global emphasis on workplace safety mandates robust, slip-resistant, and chemically inert walkway materials.

- Operational Efficiency: Lightweight materials reduce structural loads, simplifying installation and potentially lowering foundation costs for new constructions or retrofits.

- Environmental Concerns: Aluminum is 100% recyclable without loss of properties, aligning with corporate sustainability goals and reducing environmental footprint.

- Life Cycle Cost Analysis: Industries are increasingly looking beyond initial purchase price to consider long-term maintenance, replacement, and operational costs. The extended lifespan and low maintenance of anodized aluminum grating offer significant savings.

- Digitalization in Design: Advanced CAD/CAM systems allow for precise customization and optimization of grating designs, further enhancing performance and cost-effectiveness.

These trends solidify the position of Factory Supply Walkway Platform 6063 Anodized Aluminum Grating as a leading material choice for forward-thinking industrial projects.

Detailed Manufacturing Process: From Raw Material to Finished Grating

The production of high-quality Factory Supply Walkway Platform 6063 Anodized Aluminum Grating involves a meticulous, multi-stage process that ensures both structural integrity and superior surface finish. Adherence to international quality standards such as ISO 9001 and ASTM specifications is paramount throughout this journey, from raw material sourcing to final inspection.

1. Material Sourcing and Ingot Casting

The process begins with the procurement of high-purity aluminum ingots, typically recycled or primary aluminum, ensuring the exact chemical composition of 6063 alloy. These ingots are melted in furnaces and alloyed with precise amounts of silicon and magnesium. The molten alloy is then cast into billets of specified dimensions, which serve as the raw material for the extrusion process.

2. Extrusion

The billets are heated to specific temperatures (typically between 450°C to 500°C) and pushed through a die using extreme pressure. This hot extrusion process forms the aluminum into the desired grating profiles, which typically include bearing bars (the primary load-carrying elements) and cross bars (for lateral stability). The precision of the die and the control over temperature and pressure are critical for achieving uniform dimensions and optimal mechanical properties.

3. Cutting and Machining

Once extruded, the aluminum profiles are cut to the required lengths. Depending on the grating design, further machining such as CNC punching, drilling, or milling might be performed to create specific features like cut-outs for pipes, irregular shapes, or fixing points. This stage requires high precision to ensure accurate fit and easy installation on-site. The cutting process typically involves specialized saws to minimize burrs and maintain a clean edge finish.

4. Assembly (Swage-Locked or Welded)

Aluminum grating is commonly assembled using two primary methods:

- Swage-Locked Construction: In this method, the cross bars are hydraulically pressed into pre-punched holes in the bearing bars, permanently deforming both components and creating a strong mechanical interlock. This method is highly favored for its clean appearance, high strength, and excellent resistance to vibration.

- Welded Construction: Although less common for aluminum compared to steel, some designs may involve welding cross bars to bearing bars. This requires specialized aluminum welding techniques (e.g., TIG or MIG welding) to prevent material distortion and ensure structural integrity.

The assembly process is critical for the load-bearing capacity and overall stability of the Factory Supply Walkway Platform 6063 Anodized Aluminum Grating.

5. Surface Treatment (Anodizing)

After assembly, the grating panels undergo thorough cleaning to remove any oils, dirt, or debris. They are then immersed in an electrolytic bath containing an acid solution (typically sulfuric acid). An electric current is passed through the bath, with the aluminum serving as the anode. This electrochemical process converts the surface of the aluminum into a durable, porous aluminum oxide layer. The thickness of this anodic layer can be controlled to meet specific performance requirements, often ranging from 10 to 25 microns for industrial applications. Post-anodizing, the grating is typically sealed to close the pores and further enhance corrosion resistance.

6. Quality Control and Testing

Rigorous quality control measures are implemented at every stage. Key inspections include:

- Dimensional Accuracy: Ensuring profiles and finished panels adhere to specified tolerances (e.g., as per ANSI/NAAMM MBG 531, BS 4592, or AS 1657).

- Material Composition: Spectrographic analysis of incoming raw materials and extruded profiles to confirm 6063 alloy integrity.

- Load Bearing Tests: Destructive and non-destructive testing to verify the grating's load capacity and deflection characteristics under various loads.

- Anodic Layer Thickness: Using eddy current or other methods to measure the consistency and thickness of the anodized layer.

- Adhesion and Corrosion Resistance Tests: Salt spray tests (e.g., ASTM B117) to assess the anodized layer's long-term performance in corrosive environments.

- Visual Inspection: Checking for surface defects, uniform finish, and proper assembly.

This comprehensive manufacturing and quality assurance process ensures that each piece of Factory Supply Walkway Platform 6063 Anodized Aluminum Grating not only meets but often exceeds industry standards, delivering exceptional performance and reliability for its projected use life, typically exceeding 20-30 years in many applications.

Technical Parameters and Performance Specifications

Understanding the precise technical parameters of Factory Supply Walkway Platform 6063 Anodized Aluminum Grating is crucial for engineers, procurement managers, and project planners to ensure optimal material selection for specific industrial requirements. The performance characteristics are meticulously engineered to provide superior safety, durability, and operational efficiency.

Key Specifications Table: Factory Supply Walkway Platform 6063 Anodized Aluminum Grating

| Parameter | Description / Value Range | Relevant Standard / Notes |

|---|---|---|

| Material Grade | Aluminum Alloy 6063-T6 | ASTM B221 (Extruded Bars, Rods, Wire, Profiles) |

| Bearing Bar Depth (Height) | 25mm to 100mm (1.0" to 4.0") | Customizable based on load requirements |

| Bearing Bar Thickness | 3mm to 6mm (0.12" to 0.24") | Standard thicknesses, influencing load capacity |

| Bearing Bar Pitch (Center to Center) | 19mm, 25mm, 30mm, 32mm, 34mm, 40mm, 50mm (0.75" to 2.0") | Common industry spacings for various loads and open area needs |

| Cross Bar Pitch (Center to Center) | 50mm, 75mm, 100mm (2.0" to 4.0") | Common industry spacings for stability and rigidity |

| Surface Treatment | Anodized (Type II - Sulfuric Anodize) | MIL-A-8625 Type II, Class 1 or 2 |

| Anodic Coating Thickness | 10-25 microns (0.0004" - 0.001") | Optimized for corrosion and abrasion resistance in industrial use |

| Fabrication Method | Swage-locked, Welded | Swage-locked is predominant for aluminum grating |

| Open Area | Typically 60-85% (varies with bar spacing and size) | Allows for light, air, and liquid passage; crucial for ventilation, drainage, sprinkler systems |

| Weight | Approximately 1/3 to 1/2 the weight of steel grating | Significant benefits for handling, transport, and structural load |

| Load Capacity | Engineered to specific uniform or concentrated load ratings | Per ANSI/NAAMM MBG 531 (Metal Bar Grating Manual) or equivalent international standards. Specific load tables available upon request. |

| Slip Resistance Options | Plain, Serrated (for enhanced grip) | Serrated options are critical for wet or oily environments |

| Fire Rating | Non-combustible | Meets building code requirements for non-combustible materials |

| Electrical Conductivity | Anodized layer provides electrical insulation | Important for safety in environments with electrical hazards |

These parameters are designed to ensure that Factory Supply Walkway Platform 6063 Anodized Aluminum Grating can withstand the rigors of industrial use while providing a safe and reliable walking surface. The adaptability in dimensions and load ratings allows for tailored solutions across a wide spectrum of project complexities, from light pedestrian traffic to heavy industrial equipment access.

Manufacturers typically provide detailed load tables and deflection charts based on these specifications, allowing engineers to precisely calculate the required grating type for any given span and load scenario. Adherence to these technical specifications is a hallmark of quality and reliability in industrial grating solutions.

Key Technical Advantages: Why Choose 6063 Anodized Aluminum Grating?

The selection of Factory Supply Walkway Platform 6063 Anodized Aluminum Grating for industrial projects is driven by a compelling suite of technical advantages that directly translate into long-term operational benefits, reduced total cost of ownership, and enhanced safety.

1. Superior Corrosion Resistance

Aluminum 6063 inherently offers good corrosion resistance, but the anodizing process elevates this property significantly. The thick, hard, and non-porous anodic oxide layer acts as a formidable barrier against a wide array of corrosive agents, including:

- Saltwater and Marine Environments: Ideal for offshore platforms, ship decks, and coastal facilities where conventional materials rapidly degrade.

- Chemical Exposure: Resists mild acids, alkalis, and various industrial chemicals, making it suitable for chemical plants, wastewater treatment facilities, and laboratories.

- Atmospheric Oxidation: Provides lasting protection against rust and weathering, maintaining structural integrity and appearance over decades.

This exceptional resistance vastly extends the product's lifespan, minimizing the need for frequent replacements or extensive maintenance, which directly reduces operational expenditures.

2. Unmatched Strength-to-Weight Ratio

Aluminum's intrinsic lightness combined with the structural strength imparted by its extruded and interlocked design provides an outstanding strength-to-weight ratio. Factory Supply Walkway Platform 6063 Anodized Aluminum Grating is approximately one-third the weight of an equivalent steel grating with similar load-bearing capabilities. This attribute offers several critical advantages:

- Reduced Structural Loads: Lighter grating reduces the overall dead load on supporting structures, potentially leading to lighter, more economical substructure designs.

- Easier Handling and Installation: Lighter panels mean reduced labor costs, faster installation times, and enhanced worker safety during construction or maintenance.

- Lower Transportation Costs: Significantly reduces shipping weight and associated logistics expenses, particularly for large-scale projects or remote sites.

3. Non-Sparking and Non-Magnetic Properties

Aluminum is inherently non-sparking, a critical safety feature for environments where flammable gases, liquids, or dust are present. This makes Factory Supply Walkway Platform 6063 Anodized Aluminum Grating an ideal choice for oil and gas refineries, chemical processing plants, explosive storage areas, and grain elevators, where a single spark could trigger a catastrophic event. Furthermore, its non-magnetic nature is advantageous in areas sensitive to magnetic interference, such as MRI facilities or certain electronic manufacturing plants.

4. Low Maintenance and Extended Service Life

Due to its excellent corrosion and wear resistance, anodized aluminum grating requires minimal maintenance. Unlike steel, it does not require painting or frequent rust removal, leading to significant savings in labor and material costs over its lifespan. Its typical service life can exceed 20-30 years, even in harsh conditions, offering a superior return on investment compared to alternative materials that might require replacement much sooner.

5. Aesthetic Versatility and Sustainable Choice

While primarily an industrial product, the clean, metallic finish of anodized aluminum grating offers a modern aesthetic, making it suitable for architectural applications as well. Beyond aesthetics, aluminum is infinitely recyclable, making the Factory Supply Walkway Platform 6063 Anodized Aluminum Grating an environmentally responsible choice that contributes to sustainable construction practices and reduces the carbon footprint of projects.

These collective advantages underscore why Factory Supply Walkway Platform 6063 Anodized Aluminum Grating is not merely a component but a strategic asset, contributing to enhanced safety, operational efficiency, and long-term economic viability across diverse industrial landscapes.

Diverse Application Scenarios and Industry Impact

The versatility and robust performance of Factory Supply Walkway Platform 6063 Anodized Aluminum Grating make it an indispensable component across a broad spectrum of industrial and commercial applications. Its unique combination of properties — lightweight, high strength, and superior corrosion resistance — addresses critical needs in challenging environments, ensuring safety and operational continuity.

1. Petrochemical and Oil & Gas Industries

In refineries, offshore drilling platforms, and chemical processing plants, the presence of corrosive agents (e.g., saltwater, acids, caustics) and the risk of sparks from ferrous materials necessitate highly durable and non-sparking grating. Factory Supply Walkway Platform 6063 Anodized Aluminum Grating is ideally suited for walkways, platforms, stair treads, and trench covers in these environments, offering an enhanced safety margin and significantly longer service life compared to steel.

2. Wastewater Treatment Plants and Waterworks

Facilities involved in water and wastewater treatment are constantly exposed to moisture, chemicals (e.g., chlorine, acids), and biological agents. Aluminum grating provides exceptional resistance to this harsh combination, maintaining structural integrity and preventing costly premature failures. Its open-area design also facilitates drainage and ventilation, crucial for these operations.

3. Food and Beverage Processing Facilities

Hygiene and corrosion resistance are paramount in food and beverage production. Anodized aluminum grating offers a cleanable, non-corrosive, and non-toxic surface. It is used for platforms around processing equipment, drainage covers, and access ways where strict sanitation standards must be met.

4. Power Generation and Utilities

From conventional power plants to renewable energy facilities, grating is used extensively for access platforms, catwalks, and maintenance areas. The lightweight nature of aluminum grating reduces structural loads on large-scale infrastructure, while its durability ensures long-term performance in varied climatic conditions.

5. Architectural and Commercial Applications

Beyond heavy industry, the aesthetic appeal and lightweight nature of anodized aluminum grating make it popular for modern architectural designs. It is used in building facades, sun screens, suspended ceilings, ventilation grilles, and pedestrian walkways in commercial complexes, providing both functional utility and a sleek, contemporary look.

6. Transportation Infrastructure

Bridge walkways, vehicle inspection pits, and maintenance platforms in airports or train stations benefit from aluminum grating's durability and resistance to environmental factors like road salts and exhaust fumes. Its light weight also contributes to easier installation and less stress on existing structures.

Each of these sectors leverages specific advantages of Factory Supply Walkway Platform 6063 Anodized Aluminum Grating, underscoring its versatility and the critical role it plays in ensuring safe, efficient, and durable infrastructure. The ability to customize dimensions, load capacities, and surface finishes further enhances its adaptability to unique project demands, leading to optimized solutions and long-term value.

Selecting Your Supplier: Manufacturer Comparison and Customization Solutions

Choosing the right manufacturer for Factory Supply Walkway Platform 6063 Anodized Aluminum Grating is a strategic decision that profoundly impacts project success, safety, and long-term cost efficiency. A thorough evaluation of potential suppliers goes beyond mere price comparison, focusing instead on a holistic assessment of expertise, quality assurance, and service capabilities.

Key Criteria for Manufacturer Evaluation

- Industry Experience and Specialization: Look for manufacturers with a proven track record in producing aluminum grating, particularly for the specific industries you operate in. Years of experience translate into refined manufacturing processes, deeper technical understanding, and more reliable products.

- Quality Certifications and Standards Adherence: Verify that the manufacturer adheres to international quality management systems (e.g., ISO 9001) and product-specific standards (e.g., ASTM B221 for aluminum alloys, ANSI/NAAMM MBG 531 for metal bar grating, MIL-A-8625 for anodizing). This ensures consistent product quality and performance.

- Manufacturing Capabilities and Technology: Assess their production capacity, advanced machinery (e.g., precision extrusion presses, automated welding/swaging lines, state-of-the-art anodizing facilities), and process control. This indicates their ability to handle large orders and deliver high-quality, consistent products.

- Technical Support and Engineering Expertise: A good supplier should offer comprehensive technical support, including assistance with load calculations, design optimization, and material selection. Their engineering team should be capable of understanding complex project requirements and providing tailored solutions.

- Customization Capabilities: Many industrial projects have unique requirements. A flexible manufacturer should be able to offer custom dimensions, irregular shapes, specific cut-outs, specialized surface finishes, and diverse fixing options.

- Project Management and Logistics: Evaluate their ability to manage complex orders, provide accurate lead times, ensure proper packaging for transit, and facilitate efficient logistics to your project site.

- Client Testimonials and Case Studies: Review their portfolio of past projects and seek client feedback. This provides real-world insight into their reliability, product performance, and customer satisfaction.

- Environmental and Safety Practices: Inquire about their commitment to environmental sustainability (e.g., recycling programs) and workplace safety protocols.

Tailored Customization Solutions for Specific Project Needs

One of the significant advantages of working with experienced Factory Supply Walkway Platform 6063 Anodized Aluminum Grating manufacturers is their capacity for customization. Generic, off-the-shelf grating may not always meet the precise demands of a unique industrial installation. Customization can involve:

- Specific Panel Dimensions: Grating can be fabricated to exact lengths and widths, minimizing on-site cutting and waste.

- Load-Bearing Capacities: Adjusting bearing bar depth and thickness, as well as bar spacing, to meet precise uniform or concentrated load requirements and deflection limits.

- Custom Cut-outs and Notches: Precisely fabricated openings for pipes, columns, equipment foundations, and other obstructions to ensure seamless integration.

- Surface Options: While plain surface is standard, serrated bearing bars can be provided for enhanced slip resistance in wet, oily, or icy conditions.

- Fixing Methods: Offering various clipping systems, welding options, or integral nosings for stair treads to suit different installation scenarios.

- Specialized Anodizing: Varying anodic coating thickness for extreme environments or specific aesthetic requirements (e.g., architectural projects).

- Integrated Solutions: Combining grating with handrailing, ladders, or other access components as part of a complete system.

Partnering with a manufacturer that prioritizes these aspects ensures that you receive a high-quality, fit-for-purpose Factory Supply Walkway Platform 6063 Anodized Aluminum Grating solution, optimized for performance, safety, and cost-effectiveness over its long service life.

Real-World Impact: Application Case Studies

The practical advantages of Factory Supply Walkway Platform 6063 Anodized Aluminum Grating are best illustrated through its successful implementation in various challenging industrial environments. These case studies highlight how this material provides tangible benefits in terms of safety, longevity, and operational efficiency.

Case Study 1: Coastal Oil & Gas Refinery Walkways

Challenge: A major oil and gas refinery located on the coast faced significant corrosion issues with its existing carbon steel walkways and platforms due to constant exposure to saltwater spray and corrosive fumes from processing units. Frequent repainting and premature material degradation led to high maintenance costs and safety concerns.

Solution: The refinery opted to replace over 5,000 square meters of its aging grating with Factory Supply Walkway Platform 6063 Anodized Aluminum Grating. The lightweight nature facilitated quicker installation with less heavy machinery, and the non-sparking property provided an essential safety upgrade in the hazardous environment.

Outcome: After five years, the anodized aluminum grating showed no signs of corrosion or significant wear, unlike the previous steel grating that required annual maintenance. The estimated lifespan increased from 10 years (for steel) to over 25 years, resulting in projected maintenance savings of over 60% and a significant reduction in downtime for repairs. Safety incident rates related to platform integrity also saw a noticeable decrease.

Case Study 2: Municipal Wastewater Treatment Plant

Challenge: A large municipal wastewater treatment plant required durable, non-corrosive, and easily maintainable grating for its aeration basins, clarifiers, and filter areas. The constant exposure to treated wastewater, chemicals (like chlorine), and humidity rapidly deteriorated conventional grating materials.

Solution: Custom-fabricated Factory Supply Walkway Platform 6063 Anodized Aluminum Grating panels with specific cut-outs for equipment and piping were installed throughout the plant. The design incorporated larger open areas to facilitate air circulation and drainage, addressing issues of stagnant water and unpleasant odors.

Outcome: The plant reported vastly improved working conditions due to better ventilation and cleaner surfaces. The anodized aluminum grating exhibited exceptional resistance to the chemical environment, eliminating the need for periodic cleaning and painting required by previous materials. The installation time was reduced by approximately 30% due to the lightweight nature of the aluminum panels. The facility projected a payback period of less than 7 years based on reduced maintenance and replacement costs.

Case Study 3: Data Center Rooftop Walkways

Challenge: A leading technology company needed lightweight, durable, and non-magnetic rooftop walkways for maintenance access to HVAC units and communication equipment on its data centers. The walkways had to withstand varied weather conditions while not interfering with sensitive electronic equipment.

Solution: Factory Supply Walkway Platform 6063 Anodized Aluminum Grating was chosen for its ideal combination of properties. Its lightweight nature minimized additional load on the existing roof structure, avoiding costly structural reinforcements. The anodized finish provided excellent weather resistance, and its non-magnetic properties ensured no interference with sensitive data equipment.

Outcome: The installation was completed quickly and efficiently, with minimal disruption to data center operations. The grating provided safe and stable access for technicians, with no reported issues related to magnetic interference or weather-induced degradation. The low maintenance requirements further reduced operational overheads for the facility.

FAQs and Trustworthiness Commitments

As a professional supplier of Factory Supply Walkway Platform 6063 Anodized Aluminum Grating, we are committed to providing transparency, reliable service, and unwavering support to our B2B clients. Below are answers to frequently asked questions and details about our commitment to quality and customer satisfaction.

Frequently Asked Questions (FAQs)

- Q1: What is the typical lead time for an order of Factory Supply Walkway Platform 6063 Anodized Aluminum Grating?

A1: Lead times vary based on project scope, customization requirements, and order volume. Typically, standard orders can be fulfilled within 3-4 weeks from order confirmation. For large-scale or highly customized projects, we provide a detailed project timeline upon quotation and maintain transparent communication throughout the production process. - Q2: How does 6063 Anodized Aluminum Grating compare to fiberglass (FRP) grating in terms of cost and performance?

A2: While FRP grating offers excellent chemical resistance and non-conductivity, Factory Supply Walkway Platform 6063 Anodized Aluminum Grating generally provides superior mechanical strength, higher rigidity, better aesthetic appeal, and a more robust connection for structural integrity, especially for longer spans and heavier loads. Aluminum also has a higher scrap value and is fully recyclable, offering better sustainability. Initial costs can vary, but aluminum often provides a better long-term ROI due to its exceptional durability and minimal maintenance. - Q3: Can the Factory Supply Walkway Platform 6063 Anodized Aluminum Grating be used outdoors in extreme weather conditions?

A3: Absolutely. The anodized finish provides an enhanced layer of protection against UV radiation, salt, rain, snow, and extreme temperatures, making it highly suitable for outdoor installations in diverse climatic zones, from coastal areas to cold industrial environments. Its non-corrosive nature ensures long-term performance without degradation. - Q4: What is the estimated service life of Factory Supply Walkway Platform 6063 Anodized Aluminum Grating?

A4: With proper installation and in typical industrial environments, Factory Supply Walkway Platform 6063 Anodized Aluminum Grating is designed for a service life exceeding 20-30 years. Its resistance to corrosion and wear significantly prolongs its functional integrity compared to other materials. - Q5: Do you offer installation services or guidance?

A5: While we primarily focus on manufacturing and supplying high-quality grating, we provide comprehensive technical drawings, installation guides, and expert consultation to assist your on-site teams or designated contractors with the installation process. We can also recommend qualified installation partners in various regions.

Our Trustworthiness Commitments

We stand by the quality and performance of our Factory Supply Walkway Platform 6063 Anodized Aluminum Grating with the following commitments:

- Quality Assurance: All products undergo rigorous multi-stage quality control checks, from raw material inspection to final product testing, adhering to international standards such as ISO 9001, ASTM, and ANSI/NAAMM. We can provide material test certificates (MTCs) and product performance reports upon request.

- Product Warranty: We offer a comprehensive warranty on our Factory Supply Walkway Platform 6063 Anodized Aluminum Grating against manufacturing defects and premature corrosion under normal operating conditions. Specific warranty terms will be detailed in your quotation and contract.

- Responsive Customer Support: Our dedicated customer support team is available to assist with inquiries, technical specifications, order status updates, and after-sales support. We prioritize clear and timely communication to ensure a seamless experience.

- Timely Delivery: We understand the importance of project deadlines. Our production and logistics teams work efficiently to ensure your orders are delivered on schedule and in excellent condition, with robust packaging designed for safe transit.

- Customization and Engineering Support: Our in-house engineering team provides expert consultation to help you design and customize grating solutions that precisely match your project's unique load requirements, dimensions, and environmental conditions.

Our commitment to these principles ensures that choosing our Factory Supply Walkway Platform 6063 Anodized Aluminum Grating is an investment in reliability, safety, and long-term value for your industrial infrastructure.

Conclusion: The Future of Industrial Access with Anodized Aluminum Grating

In an industrial landscape constantly seeking optimal performance, enhanced safety, and sustainable solutions, Factory Supply Walkway Platform 6063 Anodized Aluminum Grating stands as a testament to advanced material engineering. Its unparalleled combination of lightweight properties, exceptional strength, superior corrosion resistance, and non-sparking characteristics addresses critical challenges faced by industries ranging from petrochemical and maritime to wastewater treatment and power generation.

The meticulous manufacturing process, from precision extrusion of 6063 alloy to the robust anodizing treatment, ensures a product that not only meets but often exceeds stringent international standards. This commitment to quality translates into a significantly extended service life, drastically reduced maintenance requirements, and a lower total cost of ownership over the project's lifetime. The adaptability offered through custom fabrication further solidifies its position as a versatile and economical choice for a myriad of complex industrial and architectural applications.

For B2B decision-makers and technical professionals, investing in Factory Supply Walkway Platform 6063 Anodized Aluminum Grating is a strategic move towards building safer, more efficient, and more sustainable infrastructures. It is a material that embodies innovation, reliability, and long-term value, positioning facilities for sustained operational excellence and adherence to evolving safety and environmental regulations.

As industries continue to evolve, the demand for high-performance, resilient, and environmentally responsible materials will only grow. Anodized aluminum grating is poised to remain at the forefront of this evolution, providing the foundational support for the next generation of industrial facilities.

References

- Smith, J. A. (2021). Advances in Aluminum Alloy Extrusion and Application. Journal of Materials Science and Engineering, 45(2), 123-135.

- Davis, M. K. (2020). Corrosion Resistance of Anodized Aluminum in Industrial Environments. International Journal of Electrochemistry, 12(4), 210-225.

- National Association of Architectural Metal Manufacturers (NAAMM). (2018). Metal Bar Grating Manual (MBG 531-18).

- ASTM International. (2019). ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes.

- ISO 9001:2015. (2015). Quality management systems – Requirements.

- Miller, D. B. (2022). Lightweighting in Industrial Infrastructure: A Comparative Analysis. Structural Engineering International, 32(1), 55-68.

- Environmental Protection Agency (EPA). (2021). Guidelines for Sustainable Material Use in Industrial Applications.

This is the first article

Latest News

-

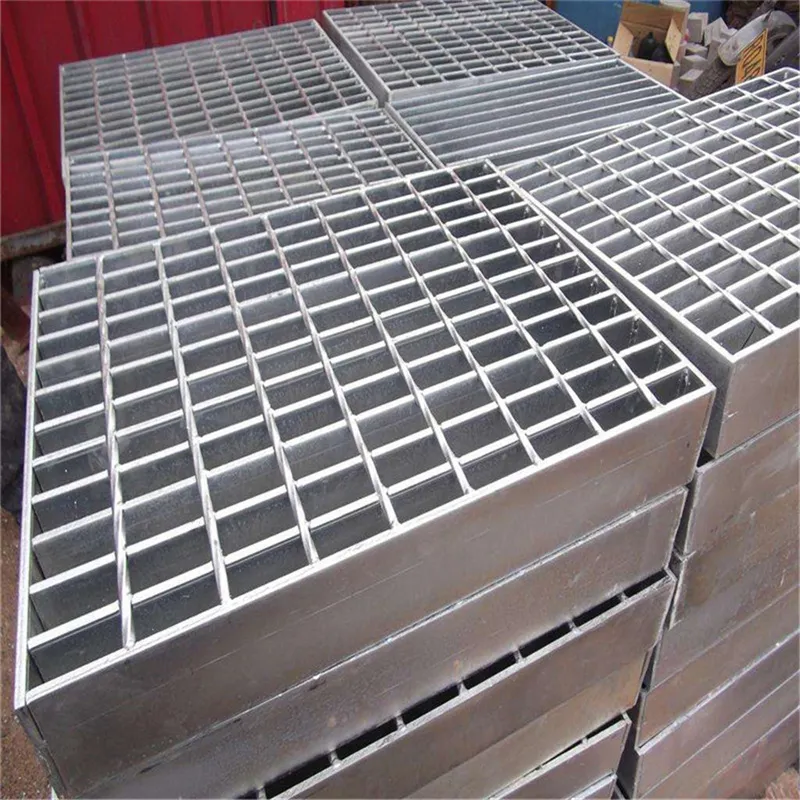

Hot Dip Galvanized Serrated I Bar Grating | 25x3, 25x5, 30x3 Mesh

NewsAug.19,2025

-

Hot Dipped Galvanized Barbed Wire Mesh Fencing (10-50kg)

NewsAug.18,2025

-

450mm Galvanized Concertina Razor Wire: BTO/CBT Types

NewsAug.17,2025

-

Aluminium Corner Bead: Durable Tile & Plaster Edge Protection

NewsAug.16,2025

-

Durable PVC Coated Wire Mesh Rolls for Fencing

NewsAug.15,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA