Agu . 27, 2025 06:00 Back to list

Galvanized Steel Grating for Platform Walkways | Welded 40x3

Introduction to Advanced Metal Grid Solutions

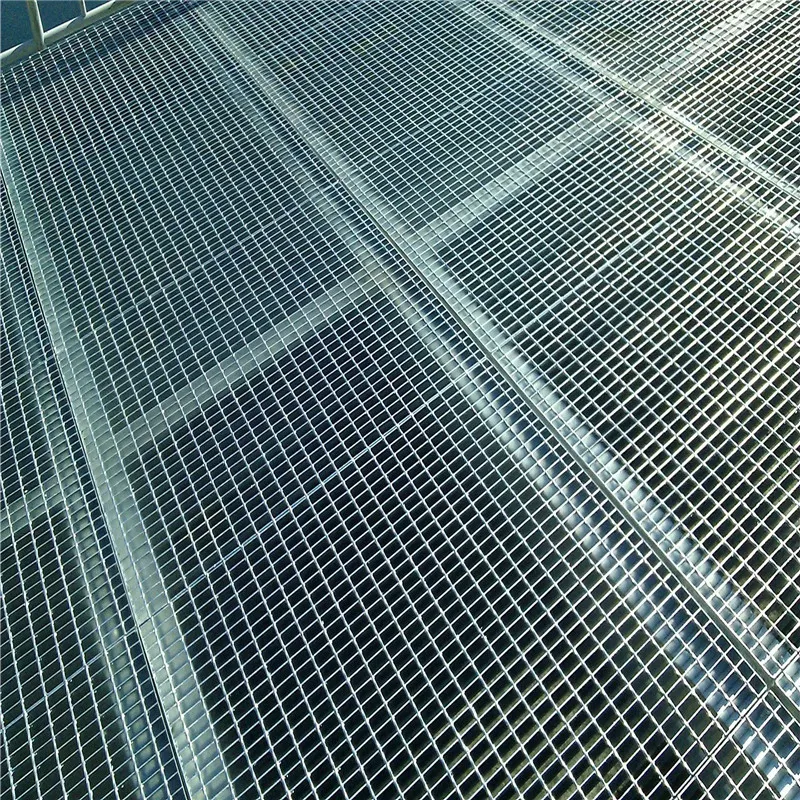

In the demanding landscape of industrial infrastructure, the selection of robust and durable flooring and platform materials is paramount for operational safety, efficiency, and longevity. Among the leading solutions, the Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway stands out as a high-performance choice. Engineered for superior load-bearing capacity and exceptional corrosion resistance, this product is meticulously designed to meet the rigorous requirements of heavy industrial applications. Its specific dimensions and material properties make it ideal for environments where safety, structural integrity, and minimal maintenance are critical considerations for B2B decision-makers and project engineers.

Industry Trends in Industrial Grating Technology

The industrial grating market is experiencing a significant evolution driven by stricter safety regulations, an increasing emphasis on sustainable materials, and the demand for enhanced durability in harsh operating environments. Key trends include the broader adoption of advanced protective coatings, such as hot-dip galvanization, to extend product lifespan and reduce maintenance cycles. There's also a growing preference for modular and customizable grating solutions that can be rapidly deployed and adapted to specific site requirements, minimizing installation costs and project timelines. Furthermore, the integration of digitally optimized design and manufacturing processes is allowing for greater precision and material efficiency. These trends collectively underscore the enduring relevance and continuous improvement of products like the Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway, ensuring it remains at the forefront of industrial infrastructure development.

- Increased Demand for Corrosion Resistance: Industries like petrochemical and offshore increasingly require materials that withstand extreme corrosive elements, leading to higher specifications for galvanization and other protective finishes.

- Focus on Safety Features: Enhanced slip resistance, secure fastening systems, and compliance with international load-bearing standards are becoming non-negotiable.

- Sustainability and Lifecycle Cost: A move towards products with longer service lives and lower lifecycle costs, reducing the environmental impact and operational expenditure.

Detailed Process Flow: Manufacturing High-Performance Grating

The production of a Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway involves a series of precision-controlled stages, ensuring the final product meets stringent quality and performance criteria. The primary material used is typically low-carbon steel, selected for its excellent weldability and structural integrity. The manufacturing process is predominantly automated to achieve consistent quality and dimensional accuracy.

Manufacturing Process Steps:

- Material Preparation: High-grade low-carbon steel flat bars (bearing bars, e.g., 40x3mm) and round or twisted square bars (cross bars) are cut to precise lengths using automated shearing machines.

- Electro-Forging (Resistance Welding): The cut bearing bars are placed vertically, and the cross bars are transversely positioned and then joined through high-power resistance welding. This process, often referred to as electro-forging, creates a robust, permanent bond without the need for filler metal, ensuring high strength and uniform spacing.

- Panel Cutting and Edging: The large welded grating panels are then precision-cut to the specified dimensions (e.g., 295x690mm). The edges are often banded with flat bars, welded to the bearing bar ends, to provide additional strength, stability, and a clean finish.

- Surface Treatment (Hot-Dip Galvanization): This is a critical stage for corrosion resistance. The steel grating is thoroughly cleaned (degreasing, pickling, rinsing, fluxing) and then immersed in a bath of molten zinc at approximately 450°C. The metallurgical reaction forms a robust, multi-layered zinc-iron alloy coating, which provides cathodic and barrier protection against rust and abrasion. This process adheres to standards like ASTM A123/A123M.

- Quality Inspection and Testing: Each grating panel undergoes rigorous inspection, including visual checks for welding integrity, dimensional accuracy, galvanization thickness, and surface finish. Load-bearing capacity tests and slip resistance evaluations are conducted in accordance with international standards.

Testing Standards and Service Life:

Products are manufactured and tested in strict adherence to international standards such as ISO 9001 for quality management, ANSI/NAAMM MBG 531-09 for metal bar grating, and relevant ASTM standards for materials and galvanization (e.g., ASTM A36 for steel, ASTM A123/A123M for zinc coating). Properly installed and maintained, a hot-dip galvanized steel grating can offer a service life exceeding 20-25 years, even in moderately corrosive industrial environments.

Target Industries and Advantages:

This type of grating finds extensive use in:

- Petrochemical: Platforms, walkways, and trench covers in refineries and chemical plants, where corrosion resistance is critical.

- Metallurgy: Elevated platforms and heavy-duty flooring in steel mills and foundries.

- Water Supply & Drainage: Covers for sumps, channels, and sewage treatment plant walkways.

- Power Generation: Boiler platforms, access ways in power plants, where high temperatures and corrosive gases may be present.

- Offshore Platforms: Providing durable and slip-resistant surfaces for maintenance and operational access in marine environments.

Key advantages in these scenarios include superior corrosion resistance from galvanization (energy saving on maintenance), high strength-to-weight ratio allowing for significant spans, excellent ventilation, and self-cleaning properties due to the open mesh structure, reducing operational hazards and upkeep costs.

Technical Specifications and Parameters

The specific configuration of a Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway is optimized for industrial applications requiring a balance of strength, durability, and cost-effectiveness. The designation '40×3' refers to the bearing bar dimensions: 40mm in height and 3mm in thickness. This profile is crucial for determining the grating's load-bearing capacity and span capabilities. The '295×690' denotes the panel's overall dimensions in millimeters, making it a highly adaptable module for various platform and walkway designs. The grating typically features a standard pitch (spacing) between bearing bars (e.g., 30mm or 40mm) and cross bars (e.g., 50mm or 100mm), engineered to optimize strength, weight, and light/airflow characteristics.

Product Specification Table:

| Parameter | Specification |

|---|---|

| Product Type | Welded Steel Bar Grating |

| Bearing Bar Dimensions (Height x Thickness) | 40mm × 3mm |

| Panel Dimensions (Width x Length) | 295mm × 690mm |

| Material | Low Carbon Steel (e.g., Q235, equivalent to ASTM A36) |

| Surface Treatment | Hot-Dip Galvanized (Min. 610 g/m² coating, per ASTM A123/A123M) |

| Bearing Bar Pitch | 30mm (standard) or 40mm |

| Cross Bar Pitch | 50mm or 100mm |

| Manufacturing Process | Electro-Forged (Resistance Welded) |

| Weight (Approx.) | Calculated based on specific mesh size and panel dimensions |

| Applicable Standards | ISO 9001, ANSI/NAAMM MBG 531-09, ASTM A123/A123M |

Versatile Application Scenarios

The robust design and durable finish of the Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway make it exceptionally versatile across a multitude of industrial and commercial applications. Its open mesh structure ensures excellent light, air, and liquid penetration, while providing a secure, slip-resistant walking surface. This product is a cornerstone for critical access and operational areas within heavy industry.

- Industrial Walkways and Platforms: Ideal for elevated access ways, maintenance platforms, and service areas in factories, power plants, and processing facilities. Its specified load capacity ensures safety even under heavy foot traffic and light equipment movement.

- Stair Treads: Can be cut and fabricated into highly durable stair treads, providing secure footing in multi-level industrial structures.

- Trench and Sump Covers: Effectively covers open trenches and sumps in various industrial settings, preventing accidental falls while allowing drainage and easy access for inspection.

- Mezzanines and Catwalks: Provides robust and well-ventilated surfaces for intermediate levels in warehouses and production facilities, optimizing vertical space.

- Architectural Features: Increasingly used in modern architecture for facades, sunscreens, and decorative elements due to its clean lines and industrial aesthetic.

Unparalleled Technical Advantages

The engineering and material choices behind the Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway endow it with a suite of technical advantages that are critical for long-term operational success in demanding environments:

- Exceptional Corrosion Resistance: The hot-dip galvanization process forms a metallurgical bond between steel and zinc, creating a highly durable, sacrificial coating. This provides superior protection against rust and environmental corrosion compared to paint or electro-galvanization, significantly extending the service life, especially in coastal, chemical, or high-humidity settings.

- High Strength-to-Weight Ratio: Despite its robust load-bearing capabilities, the open grid design minimizes material usage, resulting in a lighter product than solid alternatives. This facilitates easier handling, installation, and reduces structural load on supporting frameworks, contributing to energy saving in construction.

- Optimal Load-Bearing Capacity: The 40x3mm bearing bars, combined with the electro-forged construction, ensure that the grating can safely support significant static and dynamic loads, adhering to industry safety factors.

- Enhanced Slip Resistance: The serrated options for bearing bars and the inherent grid pattern offer excellent traction, even when wet or oily, significantly reducing the risk of slips and falls in industrial workplaces.

- Self-Cleaning and Low Maintenance: The open mesh allows debris, liquids, and snow to pass through, preventing accumulation on the surface. This property, coupled with the galvanized finish, drastically reduces cleaning and maintenance requirements, leading to lower lifecycle costs.

- Ease of Installation and Fabrication: Modular panels can be easily cut, fabricated, and installed with standard tools and fastening methods, allowing for quick deployment and custom fitment on-site.

- Ventilation and Light Penetration: The open design facilitates natural airflow and allows light to penetrate to lower levels, improving safety and reducing the need for artificial lighting, thereby saving energy.

Vendor Comparison and Authoritativeness

When sourcing critical components like the Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway, selecting the right vendor is as important as the product itself. Reputable manufacturers distinguish themselves through a combination of certified quality, extensive experience, and comprehensive customer support. A reliable vendor should demonstrate adherence to international manufacturing standards, possess a verifiable track record, and offer robust technical assistance.

Key Differentiators in Vendor Selection:

- Certifications: Look for ISO 9001 (Quality Management), CE marking for European markets, and compliance with national standards (e.g., ANSI/NAAMM in North America). These signify adherence to rigorous quality control protocols throughout the manufacturing process.

- Experience and Expertise: A vendor with 20+ years in the industry often possesses invaluable practical knowledge in grating design, fabrication, and application, translating into superior product quality and problem-solving capabilities.

- Manufacturing Capabilities: State-of-the-art facilities with advanced electro-forging equipment ensure consistent weld strength and dimensional accuracy, which is paramount for safety and ease of installation.

- Quality of Galvanization: Ensure adherence to ASTM A123/A123M standards for hot-dip galvanization thickness and uniformity, which directly impacts corrosion resistance and service life.

- Customization and Engineering Support: The ability to provide tailored solutions and professional engineering advice for complex projects.

- Customer Support and Warranty: Comprehensive pre-sales consultation, responsive after-sales service, and clear warranty commitments are crucial for a trustworthy partnership.

Product Comparison: Welded vs. Swage-Locked Grating (General)

| Feature | Welded Steel Grating (e.g., Our Product) | Swage-Locked Grating |

|---|---|---|

| Cross Bar Connection | Electro-forged/resistance welded to bearing bars. Strongest joint. | Swaged into pre-punched holes in bearing bars. |

| Load Distribution | Excellent; load transferred efficiently across all bars. | Good; but slightly less rigid than welded, especially under point loads. |

| Durability | High; permanent, rigid structure resistant to vibration and impact. | Good; but potential for cross bars to loosen over extreme long term under dynamic loads. |

| Aesthetics | Clean, uniform appearance. | Smooth, often preferred for architectural applications. |

| Primary Use | Heavy industrial platforms, walkways, robust applications. | General purpose, architectural, lighter load applications. |

Customized Solutions for Unique Project Requirements

While standard dimensions like the Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway meet many industrial needs, specialized projects often demand bespoke solutions. Leading manufacturers understand that one size does not fit all. We offer extensive customization capabilities to precisely match project specifications, optimizing both functionality and cost-efficiency.

- Custom Dimensions and Shapes: Grating panels can be fabricated to virtually any required length, width, or irregular shape to fit complex architectural designs or existing infrastructure. This includes cut-outs for pipes, columns, and other obstructions.

- Varied Bearing Bar and Cross Bar Spacing: Adjustments can be made to the pitch of bearing and cross bars to meet specific load-bearing requirements, optimize open area for ventilation or drainage, or conform to pedestrian safety standards (e.g., heel-proof grating).

- Special Surface Treatments: Beyond standard hot-dip galvanization, options like painted finishes over galvanization (duplex coating) can be provided for enhanced aesthetics or even greater corrosion protection in ultra-harsh environments. Serrated surfaces for maximum slip resistance are also a common customization.

- Material Options: While low-carbon steel is standard, stainless steel grating (grades 304, 316) can be supplied for specific applications requiring extreme corrosion resistance or hygienic properties.

- Load-Bearing Optimization: Engineering teams can calculate and recommend optimal bearing bar sizes and pitches to achieve specific load capacities and deflection limits, ensuring structural integrity and compliance.

- Fabrication and Installation Accessories: Custom stair treads with nosings, trench covers with frames, and various clip and fastening options can be designed and supplied as a complete package.

Application Case Studies

Case Study 1: Petrochemical Plant Walkways Upgrade

Client: Major South-East Asian Petrochemical Producer

Challenge: An aging petrochemical facility required the replacement of deteriorating access walkways and platforms, which were suffering from severe corrosion due to constant exposure to chemical fumes and high humidity. The new solution needed to be highly resistant to corrosive elements, ensure worker safety, and minimize maintenance downtime during installation.

Solution: Approximately 1,500 square meters of custom-fabricated Galvanized Steel Grating Welded Steel Bar (40x5mm bearing bars with 30x100mm mesh, hot-dip galvanized to ASTM A123) were supplied. Although slightly different from the primary keyword, the core principles of galvanized welded steel grating apply. The selected grating featured additional serration for enhanced slip resistance. The panels were pre-cut and banded according to detailed engineering drawings, allowing for rapid on-site installation with minimal hot work.

Results: The new galvanized grating system dramatically improved safety, providing a robust, slip-resistant, and chemically resilient walking surface. The client reported a significant reduction in anticipated maintenance cycles for the new platforms, projecting a service life of over 25 years in the harsh environment. The modular nature of the pre-fabricated panels allowed for a 30% faster installation time compared to traditional methods, minimizing operational disruption.

Case Study 2: Municipal Water Treatment Plant Trench Covers

Client: Large Metropolitan Water Authority

Challenge: The water treatment plant needed to replace numerous corroded trench covers around filtration tanks and pumping stations. The previous covers, made of painted steel, had failed prematurely due to constant exposure to moisture, disinfectants, and general wear. The new covers needed to be durable, provide secure access, and withstand continuous heavy foot traffic and occasional equipment roll-over.

Solution: Our team provided a customized solution utilizing Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway, specifically tailored to various trench widths and lengths. Each grating panel was hot-dip galvanized, meeting stringent local environmental and safety standards. The standard 40x3 bearing bar provided sufficient strength for the anticipated loads, and the robust welding ensured long-term structural integrity. We also supplied custom frames for easier installation and secure locking mechanisms.

Results: The client experienced a dramatic improvement in the longevity and safety of their trench covers. The galvanized finish proved highly resistant to the corrosive elements present in the water treatment environment, eliminating premature failure. The precise fit of the custom-sized panels ensured a seamless and safe working surface. Feedback highlighted the enhanced durability and minimal maintenance, allowing staff to focus on critical plant operations rather than grating repairs.

Frequently Asked Questions (FAQ)

- Q1: What is the typical lead time for a custom order of galvanized steel grating?

- A: Lead times can vary based on the complexity and volume of the order. For standard products, it typically ranges from 2-4 weeks. Custom orders, including design and fabrication, may extend to 4-8 weeks. We recommend contacting our sales team for an accurate quote and timeline tailored to your specific project needs.

- Q2: What kind of warranty is offered on your galvanized steel grating products?

- A: We stand by the quality of our products. We offer a standard warranty of 5 years against manufacturing defects and premature coating failure under normal operating conditions, provided the product is installed and maintained correctly. Detailed warranty terms are available upon request.

- Q3: How do I determine the correct grating type and dimensions for my application?

- A: Our experienced engineering team can assist you with this. We require details such as span length, anticipated live loads (uniform and concentrated), environmental conditions, and any specific safety requirements. Based on this, we can recommend the optimal bearing bar size, spacing, and surface treatment to meet or exceed relevant industry standards.

- Q4: What is the expected service life of hot-dip galvanized steel grating?

- A: Hot-dip galvanized steel grating, when manufactured to ASTM A123/A123M standards, can offer a service life of 20-25 years or more in typical industrial environments. In less aggressive atmospheric conditions, this lifespan can be significantly longer. Factors like humidity, industrial pollutants, and abrasion can influence the rate of zinc consumption.

Lead Time, Fulfillment, and Customer Support

We understand the critical nature of project timelines and reliable supply chains for B2B clients. Our fulfillment process is streamlined for efficiency from order placement to delivery.

- Lead Time: For standard dimensions and moderate quantities, typical production and galvanization lead times are 2-4 weeks. Larger or highly customized orders may require 6-8 weeks, depending on complexity and current production schedules. We always provide a clear and realistic lead time estimate upon quotation.

- Fulfillment & Logistics: We manage comprehensive logistics, including packaging (often in secure bundles on pallets), loading, and coordinating shipping via sea, rail, or road to ensure timely and safe delivery to your project site. International shipping documentation and customs clearance assistance are part of our service.

- Customer Support: Our dedicated customer support team is available from pre-sales consultation through post-delivery assistance. We offer technical advice on product selection, installation guidance, and troubleshooting. Our goal is to ensure complete satisfaction and foster long-term partnerships. Contact us via phone, email, or our website for prompt assistance.

Conclusion

The selection of high-quality industrial grating is a critical investment in operational safety, efficiency, and longevity. The Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate For Platform Walkway exemplifies a superior solution, combining robust engineering, advanced corrosion protection, and versatile application. Its adherence to international standards, coupled with comprehensive customization and support options, positions it as a preferred choice for demanding industrial environments. Partnering with an experienced and authoritative manufacturer ensures access to not only a premium product but also the expertise required for successful project execution.

References

- American Society for Testing and Materials (ASTM) International. ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- National Association of Architectural Metal Manufacturers (NAAMM). ANSI/NAAMM MBG 531-09: Metal Bar Grating Manual.

- International Organization for Standardization (ISO). ISO 9001:2015: Quality management systems — Requirements.

- American Galvanizers Association (AGA). How Long Does Galvanizing Last?

This is the first article

Latest News

-

Hinged HDG Anti-Slip Offshore Serrated Steel Grating

NewsAug.26,2025

-

Factory Supply 6063 Anodized Aluminum Grating Walkway Platform

NewsAug.21,2025

-

Hot Dip Galvanized Serrated I Bar Grating | 25x3, 25x5, 30x3 Mesh

NewsAug.19,2025

-

Hot Dipped Galvanized Barbed Wire Mesh Fencing (10-50kg)

NewsAug.18,2025

-

450mm Galvanized Concertina Razor Wire: BTO/CBT Types

NewsAug.17,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA