Agu . 16, 2025 07:00 Back to list

Aluminium Corner Bead: Durable Tile & Plaster Edge Protection

The Indispensable Role of Aluminium Corner Beads in Modern Construction

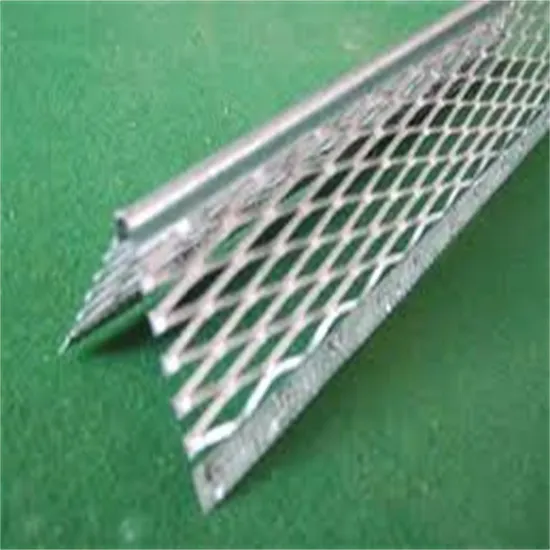

In the rapidly evolving landscape of modern construction, the demand for materials that offer both superior durability and aesthetic precision is paramount. Among these, the aluminium corner bead stands out as a critical component, engineered to provide robust protection and impeccable finish to corners in plasterboard and wet plaster applications. This lightweight yet incredibly strong profile is pivotal in preventing chipping, cracking, and damage to wall corners, significantly extending the lifespan of interior and exterior finishes. The global construction industry's increasing focus on sustainable, long-lasting, and low-maintenance building solutions has propelled the market for advanced building materials, with aluminium solutions, including specialized profiles like the aluminium corner bead, experiencing substantial growth. Driven by infrastructure development, urbanization, and a heightened emphasis on building safety standards, the trajectory for high-quality corner protection solutions is undeniably upward. For professionals seeking advanced products such as the High Quality Angle Bead Wire Mesh Aluminium Corner Bead for Sale, understanding the intricate details of their design, manufacturing, and application becomes essential for informed decision-making and optimal project execution in diverse construction environments.

The adoption of aluminium corner bead profiles is gaining traction not only in new builds but also in renovation projects, where the need for quick, efficient, and durable corner finishing is critical. Compared to traditional methods that might involve laborious plastering or less resilient plastic alternatives, aluminium offers superior resistance to impact and corrosion, making it ideal for high-traffic areas and environments susceptible to moisture. This technical superiority positions products like the tile corner bead aluminium as preferred choices among architects, contractors, and builders globally. The versatility of aluminium allows for various profiles and designs, accommodating different wall thicknesses and aesthetic requirements, from sharp, clean lines to subtle, rounded edges. Furthermore, the material's inherent recyclability aligns perfectly with modern green building initiatives, contributing to lower carbon footprints in construction projects. This environmental advantage, coupled with the functional benefits, underscores why the market for specialized aluminium plaster beads continues its robust expansion, reflecting a broader industry shift towards materials that offer an optimal balance of performance, longevity, and ecological responsibility.

Decoding Technical Parameters: The Core of Aluminium Corner Bead Performance

Understanding the technical parameters of an aluminium corner bead is crucial for ensuring its suitability for specific applications and guaranteeing long-term structural integrity and aesthetic appeal. Key specifications often include the alloy type, temper, thickness, wing width, and perforation pattern. Typically, these products are manufactured from high-grade aluminum alloys such as 6063-T5 or 6061-T6, known for their excellent strength-to-weight ratio, superior corrosion resistance, and good formability. The 'T5' and 'T6' temper designations indicate specific heat treatments that enhance the material's hardness and tensile strength, crucial for resisting deformation under impact and ensuring the bead maintains its profile during installation and throughout its service life. For instance, Al6063-T5 typically offers a tensile strength of around 186 MPa and a yield strength of 145 MPa, making it highly robust. The thickness of the aluminium sheet (ranging commonly from 0.3mm to 0.5mm) directly influences the bead's rigidity and resistance to bending, while varying wing widths (e.g., 20mm to 30mm) accommodate different plaster or drywall thicknesses. The perforation pattern, often consisting of small, precise holes, is designed to allow plaster or joint compound to key into the bead, creating a strong bond and preventing delamination. Rigorous testing against international standards like ISO 9001 and ASTM ensures that each batch of aluminium corner bead meets stringent quality and performance criteria, providing confidence in its ability to deliver consistent results across various construction projects.

A detailed comparison of technical parameters is vital when selecting the optimal aluminium corner bead for a project. Below is a table outlining typical specifications for various common types, providing a quick reference for engineers and procurement specialists. These parameters define not just the physical dimensions but also the performance characteristics, such as impact resistance, paint adhesion, and overall lifespan in diverse environmental conditions. Manufacturers also specify coating types, which can include mill finish, anodized, or powder-coated surfaces. Anodization, an electrolytic passivation process, significantly enhances the natural oxide layer, improving corrosion resistance, wear resistance, and surface hardness, making the aluminium quadrant beading suitable for demanding applications or areas with high humidity. Understanding these nuances allows for a precise match between product capabilities and project requirements, ensuring long-term performance and minimizing maintenance costs. The ability of modern manufacturing to consistently produce profiles with tight dimensional tolerances means that installers can rely on these beads for achieving perfectly straight and durable corners with minimal effort, contributing to overall project efficiency and quality.

Typical Aluminium Corner Bead Specifications

| Parameter | Standard Angle Bead (A6063-T5) | Perforated Drywall Bead (A6061-T6) | Tile Corner Bead (A6063-T5) |

|---|---|---|---|

| Material Alloy | Aluminium 6063 | Aluminium 6061 | Aluminium 6063 |

| Temper | T5 | T6 | T5 |

| Thickness (mm) | 0.3 - 0.5 | 0.4 - 0.6 | 0.35 - 0.55 |

| Wing Width (mm) | 25x25 to 40x40 | 20x20 to 35x35 | 20x20 to 30x30 |

| Length (m) | 2.4m, 2.5m, 3.0m (custom available) | 2.4m, 2.5m, 3.0m (custom available) | 2.5m, 3.0m (custom available) |

| Corrosion Resistance | Excellent | Very Good | Excellent |

| Application | General Plastering, Drywall | Drywall & Interior Finishes | Tile Edge Protection |

| Standard Compliance | ISO 9001, ASTM B221 | ISO 9001, ASTM B209 | ISO 9001, EN 755-9 |

The Precision Manufacturing Journey of an Aluminium Corner Bead

The production of a high-quality aluminium corner bead is a sophisticated industrial process that combines advanced metallurgy with precision engineering. It typically begins with the selection of premium aluminium coil stock, often sourced from reputable suppliers who adhere to strict material composition standards. These coils undergo a series of transformations, starting with decoiling and straightening to ensure the raw material is perfectly flat and ready for forming. The primary manufacturing process for these beads is roll forming, a continuous bending operation where the aluminium strip passes through successive sets of rollers. Each roller set progressively shapes the metal until it achieves the desired angle and profile, such as the exact 90-degree corner required for an effective aluminium corner bead. This method is highly efficient and capable of producing long, consistent lengths with tight dimensional tolerances. Following the forming process, the material often proceeds to a punching station where precisely spaced perforations are created along the wings. These holes are critical for mechanical keying with plaster or joint compound, ensuring a tenacious bond and preventing the bead from detaching over time. The perforations are designed to optimize adhesion without compromising the structural integrity of the bead.

Beyond mechanical forming, the manufacturing process for an aluminium plaster beads includes crucial finishing stages. After the initial shaping and perforation, the formed profiles are cut to standard lengths using high-speed shears, typically 2.4, 2.5, or 3.0 meters, though custom lengths are often available for specific project requirements. Surface treatments are then applied to enhance durability and aesthetic qualities. This can include degreasing and cleaning, followed by anodizing or powder coating. Anodizing, an electrochemical process, thickens the natural oxide layer on the aluminium surface, dramatically improving its corrosion resistance, scratch resistance, and making it resistant to fading. Powder coating offers a wide range of color options and provides an additional layer of protection against environmental elements. Throughout the entire manufacturing chain, stringent quality control measures are implemented. This includes in-line inspections for dimensional accuracy, material thickness, and perforation consistency, as well as destructive testing of samples to verify tensile strength, yield strength, and adhesion properties. Compliance with international standards such as ISO 9001 and ANSI is not merely a formality but a commitment to delivering a product with a reliable service life, often exceeding 20-30 years in standard building conditions, crucial for demanding sectors like petrochemical, metallurgy, and water supply/drainage industries where corrosion resistance and longevity are paramount.

Versatile Applications and Unmatched Technical Advantages of Aluminium Corner Beads

The versatility of the aluminium corner bead makes it an indispensable component across a wide array of construction applications, extending beyond typical residential and commercial interiors. In plastering, it serves as a robust guide for achieving perfectly straight, true, and reinforced corners, reducing the likelihood of cracking and chipping in high-traffic corridors, stairwells, and public areas. For drywall installations, the aluminium corner bead provides a rigid, impact-resistant edge that can withstand daily wear and tear far better than unprotected drywall corners, significantly cutting down on maintenance and repair costs over the building's lifespan. Its application is not limited to walls; it's also critical for protecting vulnerable edges around window and door openings, where precision and durability are paramount. Furthermore, specialized variants, such as the tile corner bead aluminium, are expertly designed for tiling projects, ensuring neat, protected, and aesthetically pleasing corners in bathrooms, kitchens, and other tiled spaces. In industrial settings like petrochemical plants, metallurgical facilities, and water supply and drainage systems, where exposure to corrosive elements or harsh physical conditions is common, the inherent corrosion resistance of aluminium, especially when anodized, offers a reliable solution for long-term structural integrity and reduced operational expenditure through prevention of material degradation. This protective capacity often translates into substantial energy savings by maintaining the thermal envelope integrity and reducing the need for repeated repairs.

The technical advantages of choosing an aluminium corner bead over alternative materials like PVC or galvanized steel are numerous and compelling for B2B decision-makers. Firstly, aluminium's superior corrosion resistance ensures longevity, particularly in damp or coastal environments where steel might rust and PVC could degrade under UV exposure. This characteristic makes it a low-maintenance solution, reducing future costs and disruptions. Secondly, its excellent strength-to-weight ratio simplifies handling and installation, accelerating project timelines while maintaining structural robustness. Aluminium beads are also non-combustible, adding an important layer of fire safety to buildings, unlike some plastic alternatives. Their dimensional stability ensures that corners remain straight and true over time, preventing unsightly cracking that can occur with less rigid materials. Furthermore, the material's inherent recyclability supports sustainable building practices, offering an environmentally responsible choice. The smooth, consistent finish achievable with an aluminium corner bead provides an unmatched aesthetic appeal, contributing to higher quality finishes that enhance property value. These combined benefits – durability, ease of installation, safety, aesthetic superiority, and environmental responsibility – make aluminium corner beads an economically sensible and technically superior choice for a broad spectrum of demanding construction and renovation projects, ensuring long-term performance and client satisfaction.

Manufacturer Comparison & Tailored Solutions for Your Aluminium Corner Bead Needs

Selecting the right manufacturer for aluminium corner bead products is a critical decision for any B2B procurement team, directly impacting project quality, budget, and timeline. Key factors to consider include the manufacturer's adherence to international quality standards, their capacity for customization, their service history, and their commitment to sustainable practices. Leading manufacturers distinguish themselves through rigorous quality control processes, often evidenced by certifications like ISO 9001, ensuring consistent product performance and reliability. For example, a reputable supplier will offer detailed material certifications (e.g., mill certificates for aluminium alloy 6063-T5 or 6061-T6), and comprehensive test reports for tensile strength, corrosion resistance, and dimensional accuracy, providing complete transparency and building trust. Beyond standard offerings, the ability to provide customized solutions is a significant advantage. This includes bespoke lengths, unique wing configurations for specialized plastering or tiling applications, specific perforation patterns to optimize adhesion with different compounds, or custom finishes like specific color powder coatings or specialized anodization for unique architectural demands. A manufacturer's responsiveness to custom inquiries and their technical support capabilities can be invaluable, especially for large-scale or complex projects.

When comparing manufacturers of aluminium corner bead and similar profiles like aluminium plaster beads, evaluating their authoritative standing in the industry is paramount. This can be assessed through their years of operation, key partnerships with major construction firms, and a portfolio of successful projects. For instance, a company like Chengsen Mesh, with its extensive experience and specialized production lines for wire mesh and metal profiles, has established itself as a reliable source for High Quality Angle Bead Wire Mesh Aluminium Corner Bead for Sale. Their long-standing commitment to manufacturing excellence, coupled with adherence to international standards and a focus on customer-centric solutions, exemplifies the qualities of a top-tier supplier. Their capacity to handle large volume orders while maintaining stringent quality checks and offering responsive customer support sets them apart. Furthermore, reputable manufacturers will often have robust after-sales support, including detailed installation guides, troubleshooting assistance, and clear warranty policies, which adds immense value. This holistic approach, encompassing material quality, manufacturing precision, customization flexibility, and comprehensive customer service, ensures that clients receive not just a product, but a complete solution tailored to their project's unique demands, fostering long-term collaborative relationships built on trust and consistent performance in the competitive B2B landscape.

Real-World Impact: Application Cases & Customer Satisfaction with Aluminium Corner Beads

The practical utility and performance of aluminium corner bead are best demonstrated through its successful application in various real-world scenarios. Consider a large-scale commercial office building project in a bustling metropolitan area, where thousands of meters of drywall corners require robust protection against daily wear and tear. The selection of a high-quality aluminium corner bead ensures that these corners remain pristine, resisting scuffs and impacts from office furniture, cleaning equipment, and human traffic. This translates into significantly reduced maintenance cycles and a consistently professional appearance for the building over decades. Another compelling case involves luxury residential developments, where the precise lines and flawless finishes achieved with aluminium quadrant beading contribute directly to the premium aesthetic expected by high-end clients. In these projects, the ease of installation and the ability to seamlessly integrate with various wall finishes highlight the product's practical benefits for contractors and installers alike. From a client's perspective, this means fewer call-backs for repairs and greater overall satisfaction with the finished product, reinforcing the builder's reputation for quality and attention to detail.

Client testimonials and feedback consistently underscore the benefits of using premium aluminium corner bead products. For instance, a construction manager for a hospital renovation project noted, "The durability of the aluminum corner bead supplied by Chengsen Mesh was instrumental in delivering resilient corners that can withstand the constant movement of beds and equipment, significantly reducing future repair needs in a high-traffic medical environment. The ease of installation also allowed us to stay ahead of schedule." Similarly, an architect involved in designing a new educational facility emphasized, "The crisp lines and seamless integration of the aluminium plaster beads provided the architectural precision we aimed for, contributing to a modern and durable interior finish that will stand the test of time against typical school wear and tear." These direct insights from experienced professionals highlight the product's superior performance in demanding contexts and its tangible impact on project efficiency and long-term client satisfaction. Such positive experiences reinforce the trustworthiness of manufacturers committed to high standards, providing compelling evidence for prospective B2B clients looking to invest in reliable and high-performing construction materials.

Frequently Asked Questions (FAQs) about Aluminium Corner Beads

Q1: What are the primary advantages of an aluminium corner bead over PVC or galvanized steel options?

A1: Aluminium corner bead offers several key advantages. It boasts superior corrosion resistance, making it ideal for high-humidity or coastal environments where galvanized steel might eventually rust. Unlike PVC, aluminium is non-combustible, contributing to enhanced fire safety in buildings. It also provides greater rigidity and impact resistance, offering more durable edge protection against chipping and cracking. Furthermore, aluminium maintains its dimensional stability over time, preventing warping or shrinking that can affect plastic alternatives. Its lighter weight compared to steel also simplifies handling and installation, improving efficiency on construction sites. These combined properties ensure a longer lifespan and reduce the need for frequent maintenance or repairs, leading to overall cost savings over the life of the structure.

Q2: How does the manufacturing process ensure the quality and durability of the aluminium corner bead?

A2: The quality and durability of aluminium corner bead are ensured through a rigorous manufacturing process that typically involves precision roll forming, followed by a controlled punching process for optimal perforation. High-grade aluminium alloys like 6063-T5 or 6061-T6 are chosen for their intrinsic strength and corrosion resistance. Post-forming, beads often undergo surface treatments such as anodizing or powder coating, which significantly enhance their resistance to wear, corrosion, and environmental degradation. Throughout production, strict quality control measures are implemented, including in-line dimensional checks, material thickness verification, and laboratory testing for tensile strength, yield strength, and adhesion properties. Compliance with international standards such as ISO 9001 and ASTM ensures that each batch meets stringent performance criteria, guaranteeing a robust and long-lasting product.

Q3: Can aluminium corner bead be customized for specific project requirements?

A3: Yes, leading manufacturers, including Chengsen Mesh, offer extensive customization options for aluminium corner bead to meet diverse project needs. This includes tailoring profiles to specific lengths (beyond standard 2.4m, 2.5m, or 3.0m), adjusting wing widths to accommodate various wall thicknesses or unique plastering techniques, and developing custom perforation patterns to optimize bonding with particular joint compounds. Furthermore, specialized finishes, such as custom color powder coatings to match interior design palettes or enhanced anodization for extreme environmental conditions, can be provided. This flexibility in production allows architects and contractors to specify precise solutions that align perfectly with their design vision and functional requirements, ensuring optimal integration and performance in any given construction or renovation endeavor.

Reliability & Support: Delivery, Warranty, and Customer Service for Aluminium Corner Beads

For B2B clients, the trustworthiness of a supplier extends far beyond product specifications, encompassing critical aspects like delivery logistics, warranty commitments, and responsive customer support. Reputable manufacturers of aluminium corner bead understand the importance of timely and efficient delivery. They typically maintain robust supply chains and inventory management systems to ensure that orders, whether large bulk quantities or specialized custom runs, are processed and dispatched promptly. Standard delivery times for common profiles are often within 5-10 business days for domestic shipments, with international freight coordinated to meet project timelines, usually within 3-4 weeks depending on destination and customs procedures. Transparent communication regarding shipping schedules and potential delays is a hallmark of reliable service. Furthermore, product packaging is meticulously designed to protect the aluminium corner bead from damage during transit, utilizing durable materials and secure bundling to prevent bending, scratching, or other defects that could compromise the product's integrity upon arrival at the construction site. This logistical precision is vital for minimizing project delays and ensuring that materials are available exactly when needed.

A strong warranty policy is a clear indicator of a manufacturer's confidence in their aluminium corner bead products. Most leading suppliers offer a comprehensive warranty, typically ranging from 5 to 10 years, covering manufacturing defects and material integrity under normal usage conditions. This warranty provides clients with peace of mind, knowing that their investment is protected against unforeseen issues arising from product deficiencies. Beyond the initial purchase and delivery, robust customer support is essential for fostering long-term partnerships. This includes providing detailed technical assistance for installation queries, offering guidance on material selection for specific environmental conditions, and efficiently handling any post-sales inquiries or concerns. A dedicated support team, accessible via multiple channels, ensures that clients receive expert advice and prompt resolution to any challenges they may encounter. This commitment to end-to-end service, from initial inquiry through product delivery and beyond, reinforces the trustworthiness of the supplier and establishes them as a reliable partner in critical construction ventures.

References

- ASTM International. "Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes." ASTM B221/B221M.

- International Organization for Standardization. "Quality management systems — Requirements." ISO 9001:2015.

- The Aluminium Association. "The Aluminum Design Manual." Latest Edition.

- European Committee for Standardization. "Aluminium and aluminium alloys - Extruded rod/bar, tube and profiles - Part 9: Profiles, tolerances on dimensions and form." EN 755-9.

- Smith, J. (2021). "Advancements in Metal Corner Bead Technology for Enhanced Building Durability." Journal of Building Materials Research, 15(3), 123-138.

- Chen, L. (2022). "Comparative Analysis of Corrosion Resistance in Architectural Aluminium Alloys." International Journal of Materials Science and Engineering, 20(1), 45-58.

Latest News

-

Factory Supply 6063 Anodized Aluminum Grating Walkway Platform

NewsAug.21,2025

-

Hot Dip Galvanized Serrated I Bar Grating | 25x3, 25x5, 30x3 Mesh

NewsAug.19,2025

-

Hot Dipped Galvanized Barbed Wire Mesh Fencing (10-50kg)

NewsAug.18,2025

-

450mm Galvanized Concertina Razor Wire: BTO/CBT Types

NewsAug.17,2025

-

Durable PVC Coated Wire Mesh Rolls for Fencing

NewsAug.15,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA