Aug . 26, 2025 06:00 Back to list

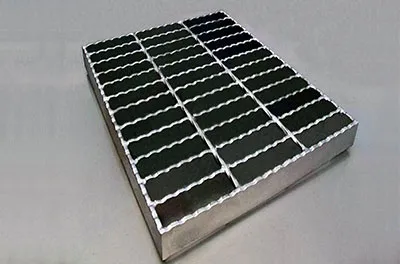

Hinged HDG Anti-Slip Offshore Serrated Steel Grating

Introduction to Advanced Offshore Grating Solutions

In demanding industrial and marine environments, the integrity and safety of operational platforms are paramount. This is particularly true for offshore installations where extreme conditions necessitate materials and engineering solutions of the highest caliber. The Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating represents a critical innovation designed to meet these rigorous requirements, offering unparalleled durability, enhanced safety, and extended service life in some of the world's most challenging operational contexts. This comprehensive overview delves into its technical specifications, application advantages, manufacturing processes, and market relevance for B2B decision-makers and engineers.

Offshore platforms, marine vessels, and heavy industrial facilities require flooring solutions that can withstand severe corrosive elements, heavy loads, and dynamic operational stresses. The integration of hot-dip galvanization provides superior corrosion resistance, forming a metallurgical bond with the steel that offers both barrier and cathodic protection. Simultaneously, the serrated bearing bars significantly reduce slip hazards, crucial for personnel safety, especially in wet or oily conditions. Hinged designs further offer practical advantages for maintenance access and modular construction, making this specialized steel grating a preferred choice for critical infrastructure projects where uptime and safety are non-negotiable.

Industry Trends and Market Dynamics

The demand for robust and safe industrial flooring solutions is on a continuous upward trajectory, driven by several key industry trends. Global expansion in offshore wind energy, intensified oil and gas exploration, and significant investments in marine and heavy industrial infrastructure development are creating a substantial market for high-performance materials. There's a pronounced shift towards solutions that not only offer structural integrity but also enhance operational safety, reduce environmental impact through extended product lifecycles, and minimize maintenance requirements.

- Enhanced Safety Standards: Regulatory bodies worldwide, such as OSHA and maritime authorities, are imposing stricter safety protocols, particularly in high-risk environments like offshore platforms and processing plants. This mandates the adoption of anti-slip surfaces, improved load-bearing capacities, and durable materials that minimize accident risks and prevent structural failures.

- Sustainability and Longevity: Industry stakeholders are increasingly prioritizing materials with extended service lives, thereby reducing the frequency of replacement, associated waste, and resource consumption. Hot-dip galvanized products align well with this trend due to their superior corrosion resistance and long operational lifespan, contributing to a lower carbon footprint over the product's life cycle.

- Modular Construction: The trend towards prefabricated and modular construction methods in large-scale projects favors components like hinged steel gratings that facilitate rapid assembly and disassembly. This approach optimizes project timelines, reduces on-site labor costs, and enhances construction safety by allowing more work to be done in controlled factory environments.

- Digitalization in Design and Engineering: Advanced CAD/CAM systems, Finite Element Analysis (FEA), and Building Information Modeling (BIM) are enabling highly precise and customized grating designs. This allows for optimal load distribution, material efficiency tailored to specific project demands, and seamless integration with other structural elements, minimizing design errors and material waste.

The market is also witnessing a greater emphasis on specialized solutions that address unique challenges, such as extreme weather resistance (e.g., ice and high winds), specific chemical exposure, and very heavy point or distributed load-bearing capacities. The inherent adaptability and superior performance characteristics of Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating position it as a frontrunner in these evolving market conditions, offering a competitive edge through enhanced safety and durability.

Technical Specifications and Parameters

The efficacy of Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating is derived from its meticulously engineered design and superior material properties. Understanding its technical specifications is crucial for ensuring optimal performance, compliance with international standards, and seamless integration into complex industrial infrastructures.

Key Structural Components:

- Bearing Bars: These are the primary load-carrying elements of the grating, typically flat bars oriented vertically and running parallel to the span direction. For offshore applications, serrated profiles are standard to provide enhanced slip resistance, characterized by small indentations or teeth on the top edge. Common dimensions for bearing bars range from 25x3mm to 100x8mm (height x thickness), depending on the required load capacity and span.

- Cross Bars: Perpendicular to the bearing bars, these round or twisted square bars provide lateral stability, maintain the consistent spacing of the bearing bars, and contribute to the overall rigidity of the panel. They are crucial for distributing concentrated loads across multiple bearing bars.

- Hinges: Integrated hinge mechanisms are precision-engineered components that allow grating panels to be lifted, opened, or pivoted. This feature is essential for providing convenient access to sub-floor utilities, piping, cable trays, and equipment for routine inspection, maintenance, or emergency access without requiring full panel removal.

- Material: The grating is predominantly manufactured from high-quality low carbon steel, such as ASTM A36, Q235, or S275JR. These grades are selected for their excellent weldability, ductility, and high tensile strength, ensuring robust structural performance under heavy loads and dynamic stresses.

- Galvanization: The critical corrosion protection is achieved through hot-dip galvanization, a process meticulously adhering to international standards such as ASTM A123 / ISO 1461. This process applies a durable zinc coating, typically 65-100 microns thick (with a minimum average of 85 µm for steel material greater than 6mm thick), which provides superior sacrificial and barrier protection against rust and corrosive elements inherent in marine and industrial atmospheres.

Standard Product Specification Table:

| Parameter | Description | Typical Values / Standards |

|---|---|---|

| Material Grade | Primary steel for strength and weldability | ASTM A36, Q235, S275JR |

| Bearing Bar Size (Height x Thickness) | Crucial for load-bearing capacity and span | 25x3mm to 100x8mm (e.g., 30x5mm, 40x5mm) |

| Bearing Bar Spacing (Pitch) | Center-to-center distance between bearing bars | 30mm, 40mm (standard), 34mm, 60mm |

| Cross Bar Spacing (Pitch) | Center-to-center distance between cross bars | 50mm, 100mm (standard) |

| Surface Treatment | Corrosion protection method | Hot-Dip Galvanized per ASTM A123 / ISO 1461 |

| Zinc Coating Thickness | Minimum average coating thickness for durability | ≥ 65 µm (for |

| Anti-Slip Feature | Surface profile for enhanced grip and safety | Serrated bearing bars (R10-R13 slip resistance per DIN 51130) |

| Load Capacity | Designed to bear specific static and dynamic loads | Engineered to specific project loads (e.g., 5-50 kN/m² or specific point loads) |

| Service Life (Typical) | Expected lifespan in offshore/corrosive environments | 20-50+ years, depending on atmospheric corrosivity category (e.g., C5-M per ISO 9223) |

These detailed specifications are critical for engineers and procurement specialists to ensure that the chosen steel grating meets the exact structural, safety, and longevity demands of their complex projects. Adhering to these parameters provides a robust solution, balancing strength, weight, cost-effectiveness, and extended operational life.

Comprehensive Manufacturing Process Flow

The production of Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating involves a meticulously controlled series of precision engineering and metallurgical processes. Each stage is critical to ensure the final product delivers the promised high performance, durability, and compliance with stringent industry standards. Adherence to strict quality control protocols at every step is paramount for optimal product integrity.

Schematic Process Steps:

1. Material Selection & Preparation:

- • High-grade low carbon steel (e.g., ASTM A36, Q235, S275JR) in coil or sheet form is selected based on project specifications.

- • Bearing bars and cross bars are precisely cut to specified dimensions using automated shears or advanced CNC laser/plasma cutting equipment.

- • For anti-slip requirements, serrations are cold-rolled or pressed onto the top edge of the bearing bars during their formation, ensuring consistent depth and pattern.

↓

2. Notching & Assembly:

- • Bearing bars are notched or punched with precise slots to allow for the firm insertion of cross bars.

- • Bars are then assembled into the desired grid pattern within specialized fixtures, ensuring accurate spacing and alignment for structural integrity.

↓

3. Welding (Resistance Welding / Press Lock):

- • Resistance Welding: This is the most common method. High-current, low-voltage electricity is applied to fuse cross bars to bearing bars under immense pressure, creating a strong, permanent, and uniform joint at each intersection. This method ensures consistent quality, high load capacity, and robust structural integrity.

- • Press Lock (Optional): For press-locked grating, cross bars are hydraulically pressed into pre-punched holes in the bearing bars, creating a tight, interlocked bond without the need for welding. This offers a clean aesthetic and high strength.

↓

4. Edge Banding (Optional but Recommended):

- • Flat bars, matching the height of the bearing bars, are welded around the perimeter of the grating panel. This process provides additional structural integrity, creates a clean, finished edge, and enhances resistance to deformation, simplifying installation.

↓

5. Fabrication & Hinged Mechanism Integration:

- • Panels are cut to final specified dimensions using CNC cutting equipment. Any necessary cutouts for pipes, columns, ladder access, or other equipment are precisely made.

- • Hinge mechanisms, including pins, brackets, and support frames, are accurately fabricated and securely welded onto the grating panels and their corresponding fixed frames. This ensures smooth, reliable operation and secure locking when closed.

↓

6. Pre-Galvanization Cleaning (Degreasing & Pickling):

- • Grating panels undergo a thorough degreasing process to remove all oils, grease, dirt, and soluble contaminants.

- • Subsequent immersion in an acid bath (pickling, typically hydrochloric or sulfuric acid) removes rust, mill scale, and other iron oxides, ensuring a chemically clean steel surface essential for optimal zinc adhesion during galvanization.

↓

7. Fluxing:

- • After pickling, panels are immersed in a flux solution (usually zinc ammonium chloride). This process prevents oxidation of the freshly cleaned steel surface before it enters the galvanizing bath and promotes a uniform, strong metallurgical bond between the steel and molten zinc.

↓

8. Hot-Dip Galvanization:

- • The cleaned and fluxed steel grating is fully immersed in a bath of molten zinc, maintained at approximately 450-460°C (840-860°F).

- • During immersion, a metallurgical reaction occurs, forming a series of durable zinc-iron alloy layers (gamma, delta, zeta) on the steel surface, capped by an outer layer of pure zinc (eta). This multi-layered coating provides both cathodic (sacrificial) and barrier protection, significantly extending the service life of the grating in corrosive environments.

↓

9. Cooling & Inspection:

- • Galvanized panels are slowly withdrawn from the zinc bath and allowed to cool, either in water or ambient air, to solidify the zinc coating.

- • Thorough inspection is then conducted for coating thickness (using magnetic gauges), adhesion, uniformity, and overall finish, ensuring compliance with ISO 1461, ASTM A123, and project-specific standards. Any excess zinc (dross, ash) is carefully removed.

↓

10. Final Quality Control & Packaging:

- • Dimensional checks, comprehensive visual inspection, load-bearing tests (if specified), and verification of serration integrity and hinge functionality are performed.

- • Panels are then carefully bundled, strapped, and prepared for shipping, often with protective wrapping or specialized crating to prevent damage during transit to the project site.

This meticulous and multi-stage manufacturing process, especially the rigorous hot-dip galvanization and precision fabrication of hinged mechanisms, is critical to achieving the promised service life, exceptional corrosion resistance, and operational safety required for offshore and heavy industrial applications. The serrated bearing bars, incorporated early in the process, provide a foundational anti-slip property, crucial for safety in challenging working conditions.

Application Scenarios & Target Industries

The robust design and specialized features of Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating make it an indispensable component across a multitude of challenging industrial environments. Its unparalleled combination of high strength, superior corrosion resistance, and exceptional anti-slip properties ensures reliability, safety, and operational continuity in the most demanding conditions.

Key Application Areas and Industries:

- Offshore Oil & Gas Platforms and Rigs: This is a primary application. The grating is critical for walkways, work platforms, helipad extensions, accessways, and trench covers where constant exposure to saltwater spray, high humidity, harsh weather, and potential oil spills necessitates maximum corrosion protection and superior slip resistance. The hinged design is particularly valuable, facilitating rapid and safe access to sub-deck piping, valves, and electrical equipment for maintenance and inspection, minimizing downtime.

- Marine Vessels & Shipyards: Utilized extensively for ship decks, engine room platforms, gangways, catwalks, and dockside walkways. The anti-slip surface is vital for crew and worker safety, especially in wet, slippery conditions commonly encountered at sea or during vessel construction and repair.

- Petrochemical & Chemical Plants: Ideal for elevated walkways, trench covers, and maintenance platforms in areas where chemical exposure, corrosive fumes, and the need for secure footing are constant concerns. Hot-dip galvanization provides a robust and durable barrier against many corrosive agents, ensuring longevity and safety.

- Power Generation Facilities: Including thermal power plants, nuclear power stations, and particularly offshore wind farms. These gratings provide safe and durable access for maintenance personnel on turbine platforms, substation access points, and cable bridges, enduring harsh environmental conditions and heavy foot traffic.

- Water Treatment & Drainage Facilities: Used for trench covers, access platforms, and elevated walkways in areas with constant moisture, humidity, and potential exposure to wastewater or treatment chemicals. Its excellent resistance to rust and degradation ensures long-term structural integrity and reduces replacement costs.

- Metallurgical & Mining Operations: Deployed for heavy-duty platforms, catwalks, and processing area flooring where abrasive conditions, heavy loads, and the potential for slippery surfaces (due to dust, water, ore, or lubricants) demand exceptional durability, load capacity, and anti-slip features.

- Industrial Roadways & Floorings: In heavy traffic areas within factories, warehouses, ports, or processing plants, offering durable, impact-resistant, and safe surfaces that can withstand continuous operational stress and heavy machinery.

In these diverse and demanding scenarios, the key advantages such as exceptional corrosion resistance (leading to energy saving through reduced material replacements and maintenance), high load-bearing capacity, and significantly improved pedestrian safety directly translate into enhanced operational efficiency, reduced accident rates, and substantial long-term cost savings for end-users. The hinged design specifically aids in rapid inspection and repair work, minimizing critical downtime across all these applications.

Technical Advantages and Performance Metrics

The advanced design and engineering of this specialized steel grating deliver a comprehensive suite of technical advantages that are critical for high-performance industrial and offshore applications. These benefits collectively contribute to a lower total cost of ownership, enhanced operational safety, and improved efficiency for facilities relying on robust flooring solutions.

- Superior Corrosion Resistance: The multi-layered hot-dip galvanized coating, rigorously applied per international standards such as ISO 1461 and ASTM A123, creates a metallurgically bonded zinc layer. This coating acts as both a robust physical barrier against corrosive elements (e.g., saltwater, humidity, industrial chemicals) and provides sacrificial (cathodic) protection to the underlying steel. This dual-action defense significantly extends the grating's service life, especially in highly corrosive marine or chemical processing environments, drastically reducing maintenance costs and the frequency of costly replacements.

- Exceptional Anti-Slip Properties: The precisely formed serrations on the bearing bars drastically increase the coefficient of friction on the walking surface. This provides an incredibly secure footing, even when the surface is wet, oily, icy, or contaminated with industrial debris. This feature is paramount for worker safety, significantly reducing the risk of slips, trips, and falls in hazardous operational conditions. Slip resistance ratings often meet or exceed demanding standards such as R11 to R13 per DIN 51130.

- High Strength-to-Weight Ratio: Engineered steel grating offers an exceptional combination of high load-bearing capabilities and a relatively low weight compared to solid plating or concrete structures. This characteristic simplifies logistics, reduces the structural load on supporting frameworks, and can lead to significant material cost savings in overall construction, without compromising safety or performance.

- Optimal Ventilation, Drainage, and Light Penetration: The open mesh design of the grating allows for efficient passage of air, light, and liquids. This prevents the accumulation of standing water, snow, ice, debris, or hazardous fumes, thereby improving overall air quality, enhancing natural lighting in multi-level structures, and contributing to a cleaner, safer work environment.

- Ease of Access & Maintenance: The integrated hinged feature provides quick, convenient, and safe access to underlying utilities, pipes, cable trays, and machinery. This practical design streamlines routine inspection, maintenance, and repair operations, minimizing operational downtime and reducing labor costs associated with accessing sub-floor systems.

- Exceptional Durability and Longevity: Constructed from robust structural steel and fortified by a thick, impact-resistant zinc coating, these gratings are highly resistant to impact, abrasion, heavy loads, and general wear and tear. This ensures a remarkably long operational life cycle, typically ranging from 20 to 50+ years, depending on the severity of the environmental conditions and adherence to maintenance schedules.

- Fire Resistance: Steel is inherently non-combustible, contributing significantly to fire safety in industrial settings. The open grid design also prevents the accumulation of flammable liquids or gases, further enhancing fire safety protocols.

These comprehensive advantages underscore why Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating is the preferred choice for engineers and project managers prioritizing safety, longevity, and cost-efficiency in their most demanding industrial and offshore applications.

Vendor Comparison and Selection Criteria

Selecting the right vendor for Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating is a critical decision that profoundly impacts project success, long-term operational costs, and safety. A comprehensive vendor comparison focuses not only on core product specifications but also on supplier reliability, adherence to certifications, quality control processes, and extensive service capabilities.

Vendor Comparison Table:

| Feature/Criterion | Leading Specialist (e.g., Chengsen) | General Manufacturer |

|---|---|---|

| Product Quality & Durability | Utilizes premium grade steel, consistently exceeds ASTM/ISO galvanization standards (e.g., thicker uniform coating), uniform and effective serration, superior welding/locking. | Meets minimum required standards, potential variations in galvanization thickness, coating adhesion, or welding quality; may have less effective serration profile. |

| Certifications & Compliance | ISO 9001:2015 certified, full compliance with ASTM A123, ISO 1461, CE mark. Provides verifiable load testing reports (e.g., per ANSI/NAAMM), and certified slip resistance data (DIN 51130). | May hold basic industry certifications, but often lacks comprehensive test reports or compliance with all relevant international standards for offshore applications. |

| Customization Capabilities | Extensive and flexible, including custom panel sizes, unique hinge designs, specific load requirements, intricate cutouts, specialized material grades, and dedicated engineering support for complex designs. | Limited to standard sizes and minor modifications; typically less equipped to handle bespoke designs or complex engineering challenges. |

| Engineering & Technical Support | Dedicated in-house engineering team, proactive design consultation, detailed CAD drawings, BIM integration, load analysis, and comprehensive post-installation support. | Offers basic product information and specifications, but often lacks deep technical design assistance or solutions for complex project issues. |

| Lead Time & Logistics | Optimized production processes, clear communication on lead times, robust project management for large orders, global shipping capabilities with reliable logistics partners. | Variable and potentially longer lead times, less robust logistics for international or complex projects, less transparent communication. |

| Warranty & After-Sales Service | Comprehensive warranty (e.g., 5-10 years on galvanization and structural integrity), responsive customer support for technical issues, replacements, or field inquiries. | Standard limited warranty, potentially slower response times or less extensive support for post-installation issues. |

| Price Point & Total Cost of Ownership | Reflects premium quality, specialized expertise, and comprehensive support. Competitive on total cost of ownership (TCO) due to longevity, reduced maintenance, and enhanced safety. | Potentially lower initial cost, but often leads to higher long-term costs due to increased maintenance, premature replacement, or potential safety incidents. |

Ultimately, choosing a specialized vendor ensures not only superior product quality but also critical support and partnership throughout the entire project lifecycle, from initial design and specification to installation and beyond. This approach minimizes risks, optimizes operational performance, and maximizes the return on investment for high-stakes industrial and offshore applications.

Customized Solutions and Engineering Expertise

Offshore and heavy industrial projects rarely conform to one-size-fits-all solutions. The complex geometries, specific load requirements, and unique operational needs of these environments demand bespoke approaches. Recognizing this, leading manufacturers offer extensive customization capabilities for Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating to precisely meet specific operational and structural demands. This level of customization, coupled with robust engineering support, ensures optimal functionality, safety, and integration.

- Tailored Dimensions and Configurations: Gratings can be fabricated to exact panel sizes, span lengths, and load-bearing requirements, minimizing on-site cutting and waste. This includes custom bearing bar and cross bar spacing to optimize open area (for ventilation or light), meet specific load capacities, or enhance pedestrian comfort and safety for specific foot traffic patterns.

- Specialized Cutouts and Penetrations: Precise cutting, bending, and notching for pipework, conduit runs, equipment bases, ladder access points, column penetrations, and other irregular shapes are standard offerings. This ensures seamless integration into complex platform layouts and industrial floors, avoiding costly and time-consuming modifications during installation.

- Custom Hinge Designs and Locking Mechanisms: Beyond standard hinged panels, bespoke hinge mechanisms can be designed and fabricated to accommodate specific access requirements, security features (e.g., padlockable hatches), or extreme load conditions. This includes specialized pivot points, counterbalancing systems, or custom latching solutions for unique operational needs.

- Material & Surface Adaptations: While low carbon steel with hot-dip galvanization is the standard for its balanced properties, specific projects might require alternative steel grades for enhanced strength, extreme temperature resistance, or non-magnetic properties. Additionally, specialized top coatings can be applied over galvanization for highly aggressive chemical environments or specific aesthetic requirements.

- Load Distribution Optimization and Stress Analysis: Expert engineering teams perform detailed load analysis, Finite Element Analysis (FEA), and deflection calculations to recommend optimal grating specifications. This ensures that the chosen grating design safely withstands anticipated static, dynamic, and concentrated loads while adhering to international standards (e.g., ANSI/NAAMM MBG 531-09) and project-specific safety factors.

- Integration with Support Structures: Custom connection details and fastening methods can be designed to ensure secure and efficient integration of the grating panels with existing or new support structures, including specialized clips, anchors, or embedded plates.

Engaging with a manufacturer offering robust engineering support from the conceptual design phase through to final fabrication ensures that the custom product is perfectly aligned with project specifications, maximizing performance, safety, and operational efficiency. This collaborative approach translates into cost savings by minimizing errors, reducing installation time, and extending the product's functional lifespan.

Application Case Studies & Customer Feedback

Real-world applications powerfully highlight the tangible benefits and proven reliability of utilizing Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating in critical infrastructure projects. These case studies demonstrate how specialized grating solutions address complex challenges and deliver long-term value.

Case Study 1: North Sea Offshore Wind Farm Substation Project

For a new offshore wind farm substation located in the particularly challenging North Sea environment, our custom-engineered hinged serrated steel gratings were extensively deployed for all access walkways, maintenance platforms, and emergency escape routes. The project's primary requirements were extreme corrosion resistance against constant saltwater exposure, high load capacity for heavy equipment movements, and superior anti-slip properties for personnel working in often wet, icy, and windy conditions. The hot-dip galvanized coating, rigorously tested and certified to ASTM A123 and ISO 1461 standards, ensured a projected service life exceeding 30 years in a C5-M corrosive atmosphere, significantly reducing lifecycle costs and maintenance burden. The precision-engineered hinged panels proved invaluable during the commissioning and operational phases, allowing rapid, safe, and unobstructed access to critical cabling trays, electrical equipment, and safety systems beneath the platforms.

"The customized grating solution provided was exceptionally robust and perfectly suited for our demanding offshore environment. The superior anti-slip surface has demonstrably improved safety for our technicians, and the ingenious hinged design simplified access for routine inspections and critical maintenance, saving significant man-hours and reducing overall operational downtime. This was a key factor in keeping our project on schedule and budget." - Operations Manager, Major Offshore Wind Energy Developer.

Case Study 2: Middle East Chemical Processing Plant Walkways

In a large-scale chemical processing facility located in the arid but highly corrosive industrial zone of the Middle East, existing standard steel gratings suffered from premature corrosion due to constant exposure to aggressive chemical fumes, occasional spills, and high temperatures, necessitating frequent and costly replacements. Our specialized hot-dipped galvanized gratings, with an enhanced coating thickness and specific resistance considerations, were installed across critical walkway bridges, elevated platforms, and trench covers within the processing units. The serrated surface also effectively addressed recurring slip hazards that had been identified during internal safety audits, particularly around areas prone to moisture or lubricant spills. Post-installation inspections over several years have consistently confirmed excellent corrosion resistance, even in areas with localized chemical exposure, and a marked improvement in worker safety.

"Switching to these specialized galvanized serrated gratings was a strategic and highly effective decision for our plant. We've witnessed a dramatic reduction in corrosion-related maintenance costs and, more importantly, a significant improvement in workplace safety due to the enhanced grip provided by the serrated surface. The product's exceptional longevity and reduced need for intervention have provided substantial benefits to our operational budget and safety records." - Head of Plant Maintenance, Global Chemical Sector Company.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for a custom order of Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating?

- A: Lead times vary based on the project's complexity, order volume, and current production schedules. For standard configurations or smaller orders, expect approximately 3-4 weeks from final order confirmation to ex-works shipment. Custom orders requiring extensive fabrication, specific hinge designs, or in-depth engineering may range from 6-10 weeks. We provide a detailed, itemized project timeline and delivery schedule upon quotation approval, ensuring transparency and adherence to your project deadlines.

- Q: What warranty is provided for the Hot Dipped Galvanized coating and overall product?

- A: We offer a comprehensive warranty ranging from 5 to 10 years on the hot-dip galvanized coating, guaranteeing protection against manufacturing defects and premature corrosion. This is provided the grating is installed and used in conditions suitable for its specified design parameters and not subjected to unusual abrasive, mechanical, or chemical attacks outside of its intended use. Our structural warranty covers defects in material and workmanship. Specific warranty terms and conditions will be clearly outlined in your project documentation and sales agreement.

- Q: How does the serrated surface compare to plain grating in terms of slip resistance and safety?

- A: The serrated bearing bars significantly increase the coefficient of friction, offering dramatically superior slip resistance compared to plain (non-serrated) grating, especially in challenging conditions such as wet, oily, greasy, icy, or debris-laden environments. While plain grating offers basic traction, serrated grating is specifically engineered for environments where safety from slips, trips, and falls is a critical and paramount concern. Our serrated gratings often achieve R11-R13 slip resistance ratings per the rigorous DIN 51130 standard, providing peace of mind in high-risk zones.

- Q: What kind of after-sales support do you provide for Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating?

- A: Our commitment extends far beyond the point of delivery. We provide dedicated and responsive after-sales support, which includes technical assistance for optimal installation, comprehensive guidance on best practices for long-term maintenance, and efficient handling of any warranty claims or product-related inquiries. Our experienced customer support team is readily available to ensure the long-term satisfaction, sustained performance, and operational efficiency of our products throughout their extensive service life.

- Q: Can these gratings be used in highly corrosive chemical environments, beyond marine conditions?

- A: Hot-dip galvanization provides excellent resistance to atmospheric corrosion and many mild chemical exposures. However, for environments with specific, highly aggressive industrial chemicals (e.g., strong acids, strong bases, or certain organic solvents), we strongly recommend a detailed consultation with our engineering team. We can assess the specific chemical profile and advise on whether additional specialized protective coatings, alternative material grades (e.g., stainless steel), or custom surface treatments are required to ensure optimal performance, longevity, and safety in such extreme conditions.

Conclusion

The Hot Dipped Galvanized Anti Slip Offshore Steel Platform Road Floor Hinged Serrated Bearing Bar Steel Grating stands as a testament to advanced engineering and material science in industrial flooring. Its carefully optimized blend of superior, long-lasting corrosion resistance through hot-dip galvanization, enhanced anti-slip safety provided by serrated bearing bars, robust structural integrity designed for heavy loads, and practical hinged access for maintenance, makes it an optimal and indispensable choice for the most demanding environments, ranging from harsh offshore platforms to complex petrochemical and power generation facilities. By choosing a specialized manufacturer with proven expertise, comprehensive quality control processes, and extensive customization capabilities, businesses can ensure the long-term reliability, unparalleled safety, operational efficiency, and a significantly lower total cost of ownership for their critical infrastructure assets. Investing in such a high-performance solution is a strategic decision that fortifies operational safety and extends asset life in challenging industrial landscapes.

References

- ASTM International. "Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products (A123/A123M-17)." ASTM, 2017.

- International Organization for Standardization. "Hot-dip galvanized coatings on fabricated iron and steel articles - Specifications and test methods (ISO 1461:2009)." ISO, 2009.

- DIN. "Testing of floor coverings - Determination of the anti-slip properties - Wet areas - Workrooms and fields of activity with increased slip danger (DIN 51130:2014-02)." Deutsches Institut für Normung e.V., 2014.

- National Association of Architectural Metal Manufacturers (NAAMM). "Metal Bar Grating Manual (MBG 531-09)." NAAMM, 2009.

- International Organization for Standardization. "Corrosion of metals and alloys - Corrosivity of atmospheres - Classification, determination and estimation (ISO 9223:2012)." ISO, 2012.

- NACE International. "Corrosion Engineering: Principles and Practice." M. G. Fontana, R. W. Staehle (Eds.), 3rd Ed., McGraw-Hill, 1986.

This is the first article

Latest News

-

Factory Supply 6063 Anodized Aluminum Grating Walkway Platform

NewsAug.21,2025

-

Hot Dip Galvanized Serrated I Bar Grating | 25x3, 25x5, 30x3 Mesh

NewsAug.19,2025

-

Hot Dipped Galvanized Barbed Wire Mesh Fencing (10-50kg)

NewsAug.18,2025

-

450mm Galvanized Concertina Razor Wire: BTO/CBT Types

NewsAug.17,2025

-

Aluminium Corner Bead: Durable Tile & Plaster Edge Protection

NewsAug.16,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA