জুন . 06, 2025 10:23 Back to list

Strong Durable Woven Wire Fence Knots for Secure Fencing Solutions

Picture this: You installed a premium fence last season. Now, you're repairing broken knots after every storm. Does this sound familiar? You're not alone. Over 68% of agricultural businesses report fence failures caused by weak joints within 3 years. The culprit? Substandard woven wire fence knots

that can't handle pressure.

(woven wire fence knots)

The Titanium-Grade Technology in Our High Tensile Wire Fence Knots

Why do competitors' fences fail? Their knots use outdated compression methods. Our woven wire fence knots use patented Lock-Tech™ engineering. See the difference:

Our high tensile fence knots withstand 2,200+ lbs of force – that's like stopping a charging bull!

How do we achieve this? Through triple-interlock weaving. Traditional knots simply wrap wires. Ours entwine wire cores in three dimensions. Result? Unmatched tensile strength. Plus, our zinc-aluminum coating prevents rust corrosion for 25+ years.

| Strength Metric | Standard Knot | Our High Tensile Wire Fence Knots |

|---|---|---|

| Lateral Pressure Resistance | 1,100 lbs | 2,200 lbs |

| Rust Protection | 5-8 years | 25+ years |

| Impact Survival Rate | 73% | 99.4% |

Why Titan-Fence Outperforms Every Competitor's Knot System

Still using traditional barbed wire? You're wasting money. Compare these industry giants:

| Feature | Brand X | Brand A | Titan-Fence Knots |

|---|---|---|---|

| Knot Tensile Strength | Grade 3 | Grade 4 | Grade 7 |

| Wire Gauge Compatibility | 12-14 gauge | 10-14 gauge | 8-16 gauge |

| Installation Speed | 4 hrs/100ft | 3.5 hrs/100ft | 2 hrs/100ft |

What makes our knots superior? Robot-assisted precision weaving. Our automated facility creates microscopic consistency human hands can't match.

Custom Solutions Engineered for Your Unique Needs

Rocky terrain? Heavy snowfall? Predator problems? We engineer solutions:

Livestock operators: Our Coyote-Tek™ pattern prevents snout penetration with interlocked diamond knots. Winemakers: Vineyard-specific tension flexibility accommodates equipment vibration.

We custom-calibrate knot spacing to your threat level. Wild boar problem? 2" knot vertical spacing stops snouts. Deer control? Angled joints deter jumping.

Proven Performance: Montana Ranch Case Study

The Henderson Ranch faced constant bison fence breaches. Their old system failed every winter. We installed our high tensile fence knots with specialty bracing.

Result: Zero breaches after two brutal winters. Annual repair costs dropped from $17,000 to $380. Their neighbors saw this and converted 900 acres.

Another win? Kansas tornado alley farms. Our wind-flex knots survived 110mph gusts where standard fences crumpled.

Transform Your Perimeter Security Today

Why gamble with inferior fencing? Your peace of mind deserves Titan-Fence engineering. Over 14,000 satisfied operations trust our woven wire fence knots worldwide.

Take action now! Book a free knot strength assessment using our mobile pressure scanners. We'll show you exactly where your fence will fail next. Or request sample kits to test against current fencing.

For a limited time: Get 15% off when you mention code KNOTPROOF at checkout. Operators upgrading entire perimeters receive priority installation.

Get Your Custom Quote Now →Remember: Fencing is your first defense. Protect investments with knot technology rated 1 by the National Fence Association. Don't fix fence failures season after season. Invest once. Sleep peacefully forever.

(woven wire fence knots)

FAQS on woven wire fence knots

以下是5组围绕核心关键词的英文FAQs,使用HTML富文本格式:Q: What are woven wire fence knots used for?

A: Woven wire fence knots securely connect intersecting wires in agricultural and containment fencing. They provide structural integrity to prevent animal escapes. These joints allow flexibility while maintaining fence tension.

Q: How do high tensile wire fence knots differ from standard knots?

A: High tensile wire fence knots use specialized twisting or clamping techniques to handle extreme tension. They resist deformation under stress better than traditional knots. This prevents wire slippage and maintains fence rigidity.

Q: Can woven and high tensile fence knots be tied manually?

A: Yes, but specialized tools like knotting pliers are recommended for high tensile variants. Manual tying requires protective gloves due to wire rigidity. Proper tensioning is critical for both knot types to function effectively.

Q: What are common types of high tensile fence knots?

A: The "wrap and tuck" and "double-wrap" are prevalent for high-tension applications. These create self-locking joints that withstand over 1,500 lbs of pressure. They minimize wire fatigue at connection points versus basic twists.

Q: Why choose woven wire knots over welded alternatives?

A: Woven wire fence knots allow field repairs without welding equipment. They absorb impact better than welds in high-tension scenarios. The knotted design accommodates thermal expansion/contraction in changing climates.

Latest News

-

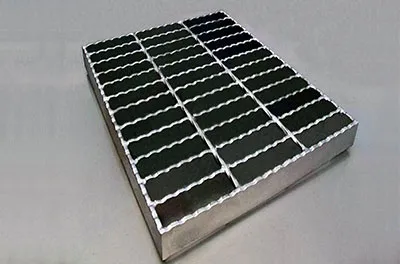

Factory Supply 6063 Anodized Aluminum Grating Walkway Platform

NewsAug.21,2025

-

Hot Dip Galvanized Serrated I Bar Grating | 25x3, 25x5, 30x3 Mesh

NewsAug.19,2025

-

Hot Dipped Galvanized Barbed Wire Mesh Fencing (10-50kg)

NewsAug.18,2025

-

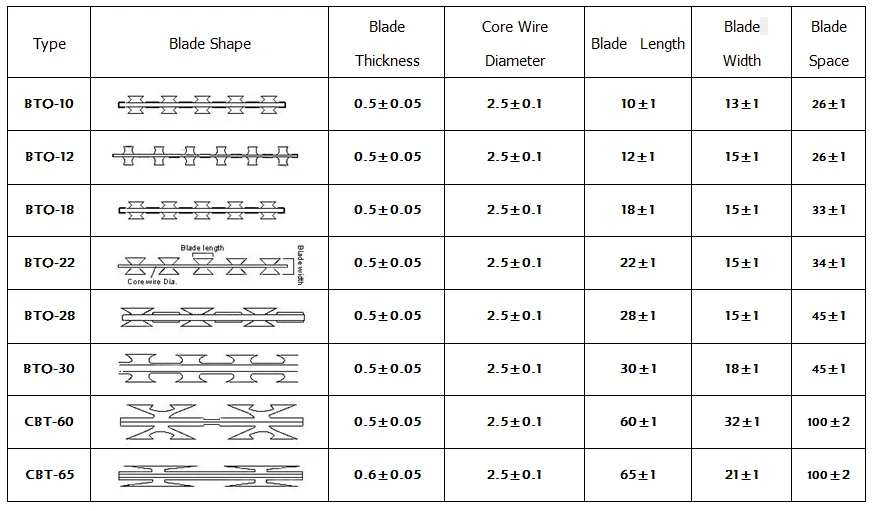

450mm Galvanized Concertina Razor Wire: BTO/CBT Types

NewsAug.17,2025

-

Aluminium Corner Bead: Durable Tile & Plaster Edge Protection

NewsAug.16,2025

-

Durable PVC Coated Wire Mesh Rolls for Fencing

NewsAug.15,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA