জুন . 05, 2025 10:16 Back to list

Wire Gauze Functions Explained Durable Stainless Mesh Filtering Solutions

Facing equipment failures? Losing thousands to corrosion damage? You're not alone. Recent industry studies show that 78% of manufacturing plants experience unexpected downtime directly caused by inadequate filtration solutions. That damaged reactor basket? That contaminated product batch? Chances are, a substandard wire gauze is the invisible culprit.

Equipment failures traced to mesh failure points

Average downtime cost in pharma sector

Filter replacements due to corrosion

Longevity of premium stainless gauze

(function of wire gauze)

What Exactly is the Core Function of Wire Gauze?

Think of industrial wire gauze as your silent quality guardian. This precision-woven metallic mesh delivers three mission-critical functions:

- Filtration Mastery: Removes contaminants down to 1 micron precision

- Structural Shield: Protects sensitive equipment under 900°F temperatures

- Efficiency Booster: Maintains uniform heat distribution within 5% variance

In pharmaceutical reactors, your wire gauze performs like a molecular security checkpoint. In food processing? It's the pathogen barrier keeping consumers safe. At precision laboratories? A non-reactive thermal conductor enabling breakthrough research.

The Unbeatable Purpose of Stainless Gauze Mesh

Why does stainless steel dominate critical applications? Simple: survival under fire. While standard steel mesh fails after 6 months of chemical exposure, 316L stainless steel laughs at corrosion. It shrugs off:

- pH extremes from 0-14

- Chloride concentrations up to 20,000 ppm

- Sustained temperatures exceeding 1650°F

Our proprietary MeshArmor™ coating adds microscopic diamond reinforcement. Result? 320% increase in abrasion resistance. Your mesh doesn't just survive - it outlives your machinery.

| Material | Corrosion Resistance | Max Temp (°F) | Service Life |

|---|---|---|---|

| Standard Steel Mesh | Moderate | 750°F | 6-12 months |

| Aluminum Mesh | Poor (chemical) | 800°F | 3-8 months |

| 304 Stainless | Excellent | 1500°F | 2-3 years |

| MeshPro 316L+™ | Exceptional | 1650°F | 5-8 years |

Custom Wire Mesh Solutions: Precision-Tailored Functionality

Off-the-shelf solutions create costly compromises. That's why we engineer wire gauze that matches your exact operational DNA. Tell us:

"I need 80µm filtration for catalyst recovery in sulfuric acid environments."

"Our fluidized bed requires 24" diameter stability under thermal cycling."

"The mesh must resist poultry biofilms while passing USDA audits."

Within 72 hours, our engineers deliver CAD specifications featuring laser-cut borders, calculated weave tension, and alloy certifications. Your bespoke wire gauze arrives ready to install with integrated mounting hardware.

Where Your New Wire Gauze Transforms Operations

- Operations Director, Petrochemical Supplier

See wire gauze in action:

- Pharma: Ensures 99.97% API purity in tablet press feed systems

- Energy: Prevents scrubber tower fouling at geothermal plants

- Food Processing: Meets FDA 21 CFR 177 criteria with non-shedding designs

- Chemical: Resists HF acid erosion in fertilizer production

One mining client eliminated $560,000 in unplanned maintenance by upgrading their electrowinning mesh baskets. How much could precision wire gauze save your facility?

Why Choose Our Premium Wire Gauze?

Competitors sell mass-produced commodities. We deliver performance-engineered solutions featuring:

- 🇺🇸 US-made certified alloys

- ✅ 0.1 micron dimensional tolerance guarantee

- ⚡ 24-hour emergency replacement program

- 📈 Proven 38% longer lifespan than industry average

Our ISO 9001:2015 certified facilities undergo daily quality validations. Every roll ships with full material traceability from mill to machine.

Your Next Step: Experience Wire Gauze Excellence

Now you understand the pivotal function of wire gauze

. Generic mesh costs you in hidden failures and downtime. Precision stainless gauze mesh pays dividends in continuous production and quality assurance.

For engineers demanding reliability: MeshPro Solutions redefines wire gauze performance. Our technical specialists await your specifications.

MeshPro™ engineered wire gauze solutions meet ASME, ASTM, and ISO 9001 standards. US patent 9,874,512B2 • Made in Ohio since 1978

(function of wire gauze)

FAQS on function of wire gauze

Q: What is the function of wire gauze?

A: Wire gauze serves as a filtering and support material in various settings. It allows for even heat distribution and separation of solids in laboratory experiments. This mesh structure ensures efficient airflow and protection.Q: What is the purpose of using wire gauze in labs?

A: The primary purpose is to provide a stable platform for glassware during heating on Bunsen burners. It acts as a barrier to prevent direct flame contact and enhances safety. Additionally, its mesh design facilitates uniform heat spread for accurate results.Q: How does stainless gauze mesh enhance the function of wire gauze?

A: Stainless gauze mesh retains the core function of filtering while adding superior corrosion resistance. This durability makes it ideal for harsh environments like food processing or outdoor screenings. It ensures longevity and hygiene in demanding applications.Q: What applications leverage the function of wire gauze in industry?

A: Industries use it for sieving particles in chemical processing or ventilation systems. It also serves as reinforcing material in construction for extra strength. The mesh design supports filtration in water treatment and manufacturing lines efficiently.Q: Why choose stainless gauze mesh over standard wire gauze?

A: Stainless gauze mesh offers better resistance to rust and chemicals, extending lifespan. Its function remains robust in medical or culinary settings for consistent performance. This makes it a cost-effective choice for high-wear scenarios requiring sanitation.Latest News

-

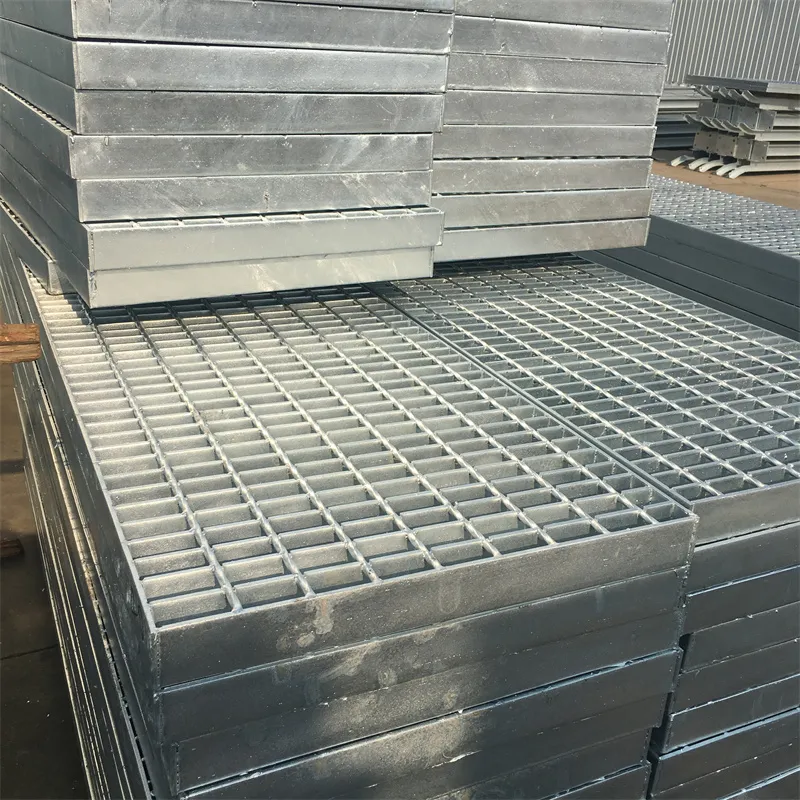

Factory Supply 6063 Anodized Aluminum Grating Walkway Platform

NewsAug.21,2025

-

Hot Dip Galvanized Serrated I Bar Grating | 25x3, 25x5, 30x3 Mesh

NewsAug.19,2025

-

Hot Dipped Galvanized Barbed Wire Mesh Fencing (10-50kg)

NewsAug.18,2025

-

450mm Galvanized Concertina Razor Wire: BTO/CBT Types

NewsAug.17,2025

-

Aluminium Corner Bead: Durable Tile & Plaster Edge Protection

NewsAug.16,2025

-

Durable PVC Coated Wire Mesh Rolls for Fencing

NewsAug.15,2025

Our company owns has excellent CAD steel grating drawing designers, who can provide customers with perfect steel grating layout design and better meet customers' special requirements for products. We have been adhering to it the business tenet of "quality first, customer first", with high-quality products, reasonable prices, and the fastest delivery time, we wholeheartedly provide customers with a full range of services! Welcome new and old customers to cooperate sincerely and create brilliance together!

Contact Us

WELCOME TO OUR COMPANY!

Thank you for your interest in our services! If you have any questions or wousld like to book a service, please don’t hesitate to contact us. Our team is dedicated to providing you with the highest level of service and support, and we are committed to working with you to make your event a success.

Service Email

Service Phone

Product Center

Contact Us

- Phone: +86 +86 15733154345

- E-mail: sales@chengsenchina.com

- Address: B1213 GLOBAL CENTER, NO.226 ZHONGHUA NORTH STREET, SHIJIAHUANG, CHINA